12 2a, Hydraulic system, Hydraulic pump flow test – SkyTrak 8042 Service Manual User Manual

Page 430

8.15

Model 8042, 10042, 10054 Legacy

Rev. 10/03

Hydraulic System

Engine Information

Idle . . . . . . . . . . . . . . . . . . . . . 1,050 ±50 rpm

Full Speed. . . . . . . . . . . . . . . 2,750 ±100 rpm

Hydraulic Oil Information

Oil Type - 10W, meet ISO Grade 46

Capacity - Reservoir . . . . . 32.2 gal. (127 liter)

Capacity - System. . . . . . . . 64 gal. (242 liter)

Note: To adjust relief settings, pressure reducing

settings or standby pressure, turn the

adjustment screw clockwise to increase

pressure or counterclockwise to decrease

pressure.

The hydraulic oil temperature for the pump flow

test should be between 100-120° F (38-49° C)

(tank hot to the touch) during testing.

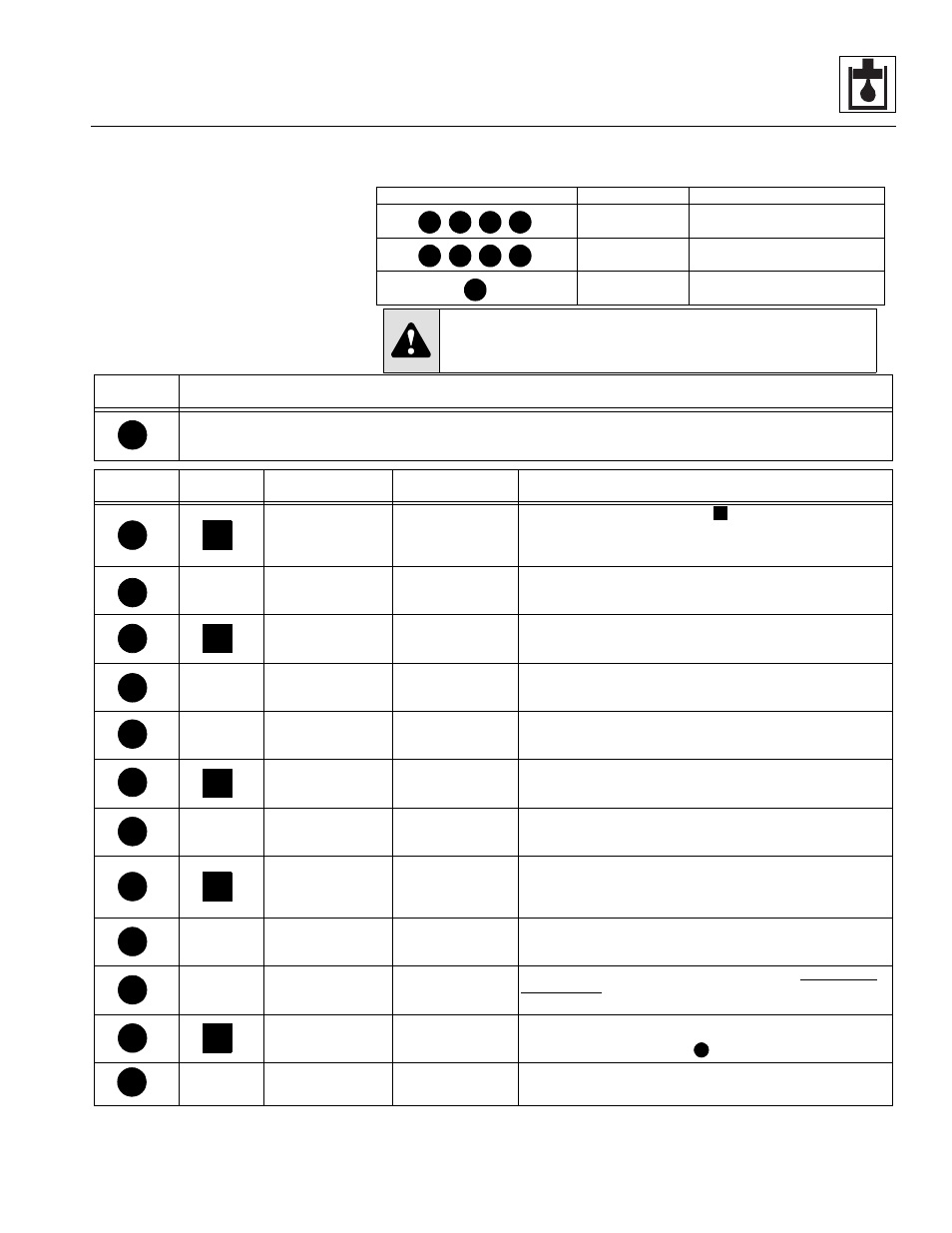

Equipment Needed to Perform Tests

from Hydraulic Diagnostic Test Kit

Test Location

Gauge

Fittings

4,000 psi gauge

(280 bar gauge)

Unit equipped with fittings from

factory.

1,000 psi gauge

(70 bar gauge)

Unit equipped with fittings from

factory.

4,000 psi gauge

(280 bar gauge)

Requires a male or female quick

disconnect coupler

TEST

LOCATION

Hydraulic Pump Flow Test

To check flow readings, a flow meter capable of measuring 60 gpm (3,8 liter/sec) and a load valve capable of

6,000 psi (413,4 bar) will be required (not included with Hydraulic Diagnostic Test Kit).

2,000 psi (137,8 bar) load @ Engine Speed of 2,500 ±25 rpm — Flow rate should be 48.9 GPM (3 liter/sec).

TEST

LOCATION

ADJUST.

LOCATION

COMPONENT

DESCRIPTION

PRESSURE

READINGS

PRESSURE TEST PROCEDURES

Pump Standby

Pressure

550-600 psi

(38-41 bar)

Loosen load sense line at location

to bleed off pressure, and

then retighten line. With engine at idle and no hydraulic functions

operated, check pump standby pressure. If pressure is incorrect,

adjust top screw on compensator.

N/A

Pump Pressure

Compensator

3,300 psi

(228 bar)

With engine at idle, turn steering wheel all the way in one direction.

Hold over relief and check maximum pump pressure. If pressure is

incorrect, consult factory.

Main Control Valve

System Relief

3,000 ±100 psi

(207 ±7 bar)

With engine at FULL throttle, use the boom control lever to fully

retract the boom. Hold over relief and check pressure. If pressure is

incorrect, adjust or replace cartridge.

N/A

Attachment Tilt Relief/

FORWARD or

REARWARD

3,000 ±100 psi

(207 ±7 bar)

CONSULT FACTORY

N/A

Secondary Function

Manifold

Load Sense

0-3,000 psi

(0-207 bar)

With engine at idle, load sense is 0 psi.

With engine at idle, use the boom control lever to fully retract the

boom. Hold over relief. Pressure should be 3000 psi (207 bar).

Secondary Function

Manifold

Steering Relief

2,500 ±100 psi

(172 ±7 bar)

With engine at idle, turn the steering wheel all the way in one

direction. Hold over relief and check pressure. If pressure is

incorrect, adjust or replace the pressure reducing cartridge.

N/A

Secondary Function

Manifold

Park Brake Release

550 ±50 psi

(38 ±3,4 bar)

With engine at idle and no hydraulic functions operated, disengage the

park brake and check pressure. This is not an adjustment.

Secondary Function

Manifold

Park Brake Pressure

550 ±50 psi

(38 ±3,4 bar)

With engine at idle and park brake released, turn the steering wheel all

the way in one direction. Hold over relief and check pressure. If

pressure is incorrect, adjust or replace the pressure reducing cartridge

in the secondary function manifold.

N/A

Brake Valve

(Manual Brake

Pressure)

400 psi minimum

(28 bar)

With engine OFF, pump brake pedal twice. DO NOT overstroke the

brake pedal. If pressure is incorrect, check for external leaks. If no

leaks are found, refer to service manual brake system information.

N/A

Brake Valve

(Service Brake

Pressure)

550 psi minimum

(38 bar)

With engine at idle, depress and hold brake pedal. DO NOT turn

steering wheel. DO NOT overstroke the brake pedal. Check

pressure. If pressure is incorrect, consult service manual.

Auxiliary Hydraulics

3,000 psi

(207 bar)

With engine at low idle, move auxiliary control lever left or right. Hold

auxiliary control lever over relief and check pressure. If pressure is

incorrect, check main relief per

.

N/A

Stabilizer Cylinder

75-150 psi

(5,2-10,3 bar)

With the engine at idle, check the pressure on the cylinder.

3

4

5

2

7

8

10

6

9

CAUTION: GAUGE DAMAGE may occur. Malfunctioning hydraulic system circuits

may have excessive pressure and can cause hydraulic pressure spikes. Test circuit

with the highest reading pressure gauge first. If this gauge cannot record an

accurate pressure reading, use the next lower pressure gauge.

1

2

2a

2b

2

3

3a

3

4

5

4

6

7

5

8

8

9

3b

3

10