SkyTrak 8042 Service Manual User Manual

Page 183

Boom

3.122

Model 8042, 10042, 10054 Legacy

Rev. 03/04

Environments in which material handling vehicles

operate can vary widely, from outdoor moisture to mildly

corrosive or highly corrosive industrial atmospheres, in

addition to abrasive exposures such as sand and grit.

Some effects can be as follows:

• Moisture - Corrosive rusting reduces chain strength

by pitting and cracking.

• Temperature - Low temperature reduces chain

strength by embrittlement. Going in and out of cold

storage results in moisture from condensation.

• Chemical Solutions or Vapors - Corrosive attack on

the chain components and/or the mechanical

connections between the chain components.

Cracking can be (and often is) microscopic. Going

from microscopic cracking to complete failure can be

either abrupt or may require an extended period of

time.

• Abrasives - Accelerated wearing and scoring of the

articulating members of the chain (pins and plates),

with a corresponding reduction in chain strength.

Due to the inaccessibility of the bearing surfaces (pin

surfaces and plate apertures), wear and scoring are

not readily noticeable to the naked eye.

Following are some examples of dynamic shock loading

which can impose abnormal loads above the endurance

limit of a leaf chain:

• High velocity movement of load, followed by sudden,

abrupt stops.

• Carrying loads in suspension over irregular surfaces

such as railroad tracks, potholes and rough terrain.

• Attempting to “inch” loads which are beyond the

rated capacity of the vehicle.

The above load cycles and environmental conditions

make it impossible to predict chain life. It is therefore

necessary to conduct frequent inspections until

replacement life can be predicted.

The boom chain’s normal life expectancy can be expressed

as a maximum percent of elongation. This is generally

3% of pitch. As the chain flexes back and forth over the

sheave, the bearing joints (pins and inside link plates)

gradually incur wear due to articulation.

a. Inspection Guidelines

Expose the extend and retract chains (refer to Section

3.7.1, b. “Expose Extend Chains for Inspection,” Section

3.7.1, c. “Expose Intermediate Boom Retract Chain for

Inspection,” or Section 3.7.1, d. “Expose Inner Boom

Retract Chain for Inspection.”) and inspect the chains for

the following conditions:

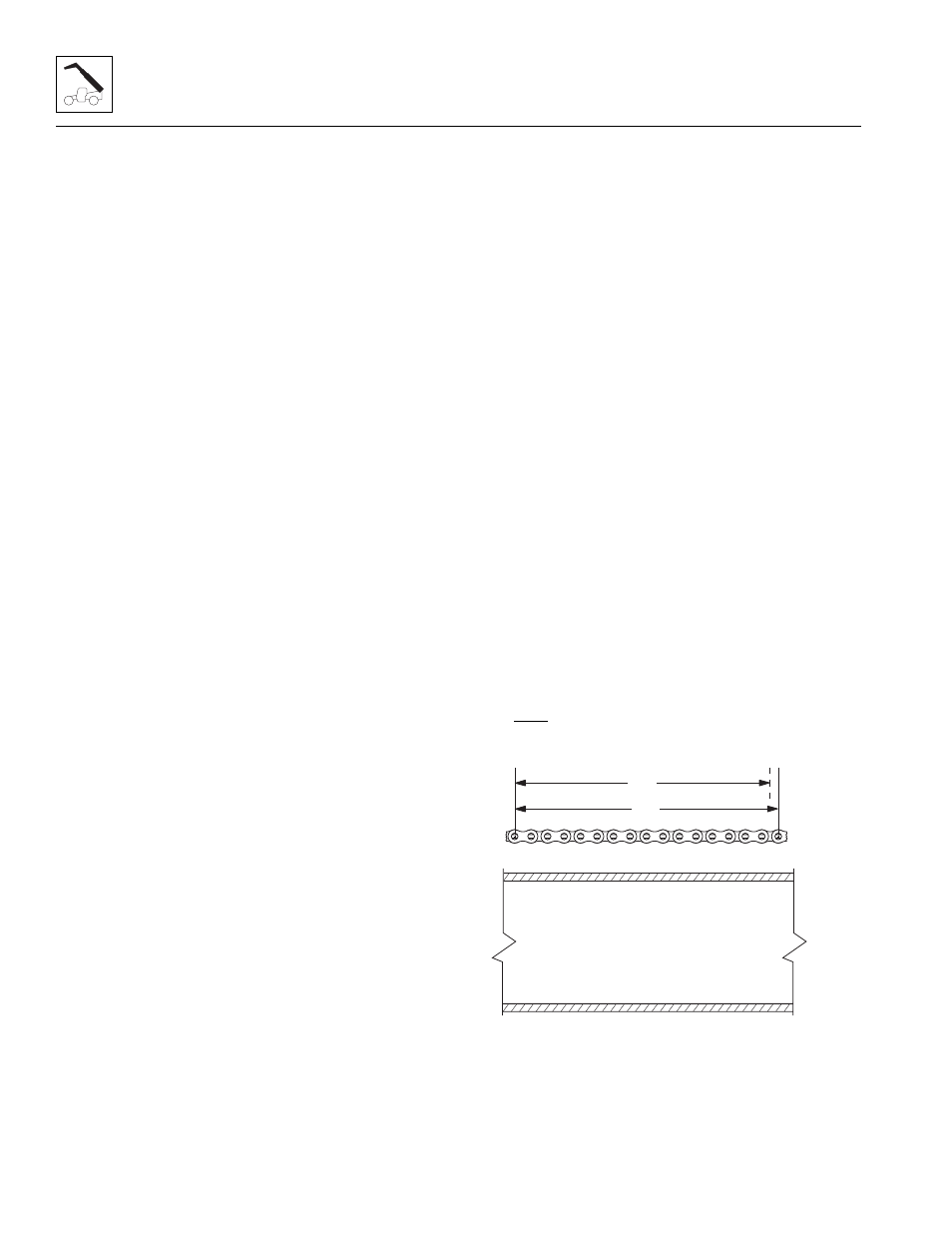

Elongation

When the original length (1) of 12" (305 mm) per foot of

new chain has elongated from wear to a length (2) of

12.36" (313 mm), the chain must be discarded and

replaced. (Refer to Section 3.7.6, “Boom Extend and

Retract Chains Removal and Replacement.”)

It is important to measure the chain in the section that

moves over the sheaves because it receives the most

frequent articulation. Measuring the chain near its clevis

terminals could give an inaccurate reading.

Intermediate Extend Chains and Retract Chains

Measure across a span of 17 pins at the center of the

chain. Measure from pin center to pin center.

Inner Extend Chain

Measure across a span of 13 pins at the center of the

extend chain. Measure from pin center to pin center.

All Chains

The maximum measurement allowed is 12.36" (313 mm).

If the measurement is more than 12.36" (313 mm), the

chain must be replaced. (Refer to Section 3.7.6, “Boom

Extend and Retract Chains Removal and Replacement.”)

MM2120

1

2