7b.8.3 fuel level sender and gauge, 7b.8.4 fuel lift pump inspection and testing, 7b.8.5 fuel filter – SkyTrak 8042 Service Manual User Manual

Page 395: 7b.8.6 venting air from the fuel system, 7b.8.7 fuel injectors, 7b.8.3, Fuel level sender and gauge b.28, 7b.8.4, Fuel lift pump inspection and testing b.28, 7b.8.5

Engine: Cummins QSB4.5T

7B.28

Model 8042, 10042, 10054 Legacy

Rev. 10/03

7B.8.3

Fuel Level Sender and Gauge

The fuel level sender and gauge assembly is described in

Section 9.14.15, “Fuel Level Indicator and Fuel Level

Sender.”

7B.8.4

Fuel Lift Pump Inspection and Testing

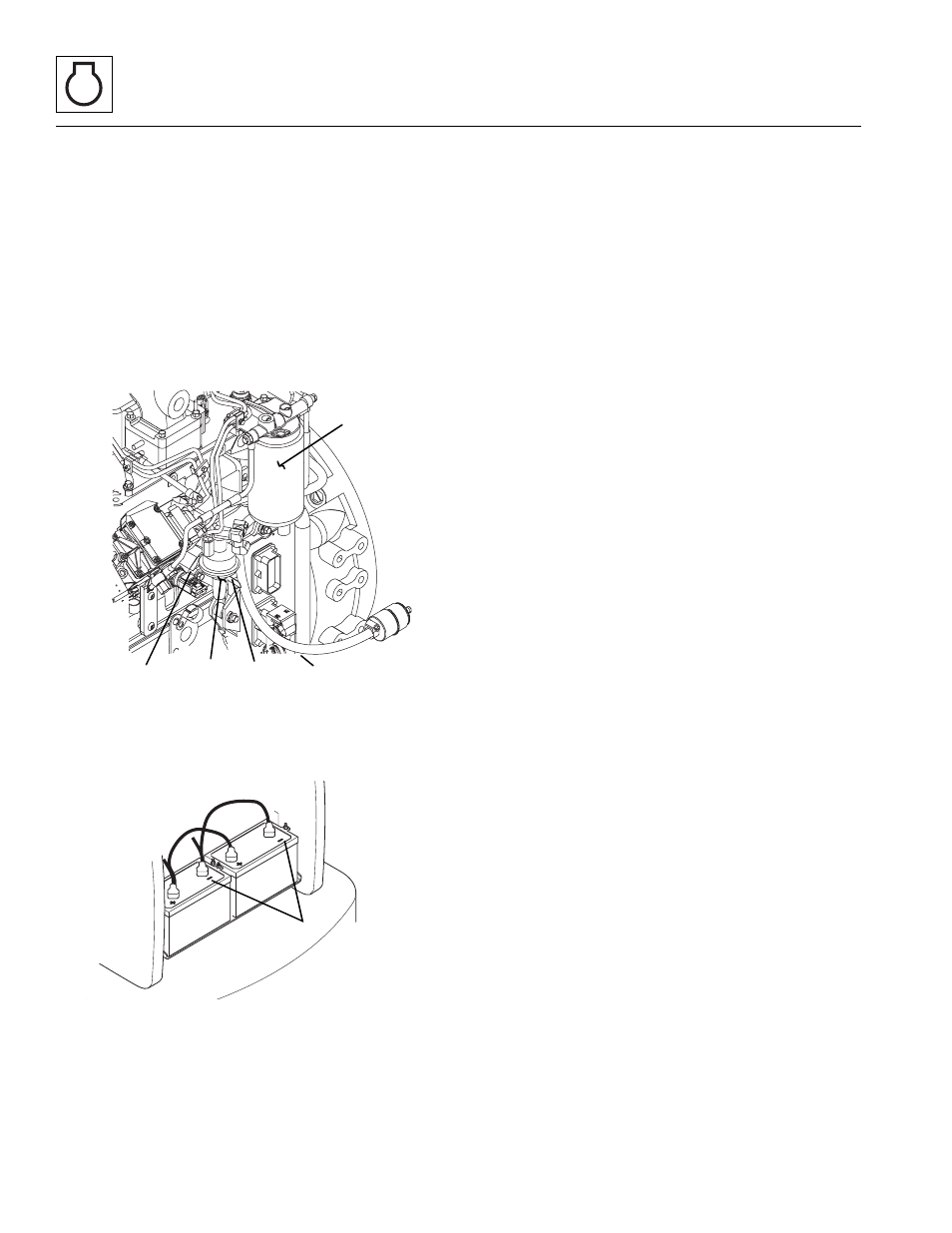

1. To test the diaphragm, remove the fuel inlet line (1)

from the fuel lift pump (2). Block the fuel inlet with a

finger and operate the hand plunger (3). A properly

operating pump will provide suction that will remain

until the finger is removed from the inlet.

a. Fuel Lift Pump Removal

1. Disconnect the negative (-) battery cables (6) from the

batteries.

2. Clean debris from around the fuel lift pump (2).

3. Disconnect the fuel inlet line (1).

4. Remove the capscrews (5), gasket and fuel lift

pump (2).

b. Cleaning and Drying

Clean the exterior of the pump with mineral spirits, and

blow dry with compressed air.

Note: Parts replacement is not practical. The fuel lift

pump is serviced as an entire assembly.

c. Fuel Lift Pump Installation

1. Clean the mounting surface on the cylinder block.

2. Install the fuel lift pump (2) with a new gasket. Install and

torque the capscrews (5) to 18 lb-ft (24 Nm).

3. Connect the fuel line (1). Vent air from fuel system.

Refer to appropriate Owners/Operators Manual.

4. Connect the negative (-) battery cables (6) to the

batteries.

7B.8.5

Fuel Filter

Refer to the appropriate Owners/Operators Manual for

your vehicle for the correct fuel filter (4) removal procedure.

7B.8.6

Venting Air from the Fuel System

Refer to the appropriate Owners/Operators Manual for

your vehicle for the correct fuel system venting procedure.

7B.8.7

Fuel Injectors

The engine uses Bosch 17-mm, closed nozzle, hole-type

injectors. The injectors have different part numbers for

different engine ratings. The last four digits of the Cummins

part number (stamped on the bottom portion of the

injector) identify the injector.

IMPORTANT: Use only the specified injector for the engine.

Damage to the engine can occur if incorrect injectors are

used.

During the injection cycle, high pressure from the

injection pump rises to the operating (or “pop”) pressure,

which causes the needle valve in the injector to lift. Fuel

is then injected into the cylinder. A shimmed spring is

used to force the needle valve closed as the injection

pressure drops below the pop pressure to seal off the

nozzle after injection.

Failure of the needle valve to lift and to close at the

correct time, or a needle valve that is stuck open, can

cause the engine to misfire and produce low power. Fuel

leaking from the open nozzle can cause a fuel knock,

poor performance, smoke, poor fuel economy and rough

running.

MH4660

1

2

3

4

5

MH4440

6