SkyTrak 8042 Service Manual User Manual

Page 31

General Information and Specifications

2.6

Model 8042, 10042, 10054 Legacy

Rev. 10/03

b. Straight O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in leaking joints.

Under tightening of the fitting will result in the fitting

loosening during normal operation and the joint leaking.

Damaging the o-ring during assembly will result in

immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the bad part must not be used.

Clean any foreign material from the mating parts

before assembly.

2. Lubricate the o-ring and male thread with a clean

petroleum based lubricant.

3. Screw the fitting into the port.

4. Torque the fitting to the values found in table.

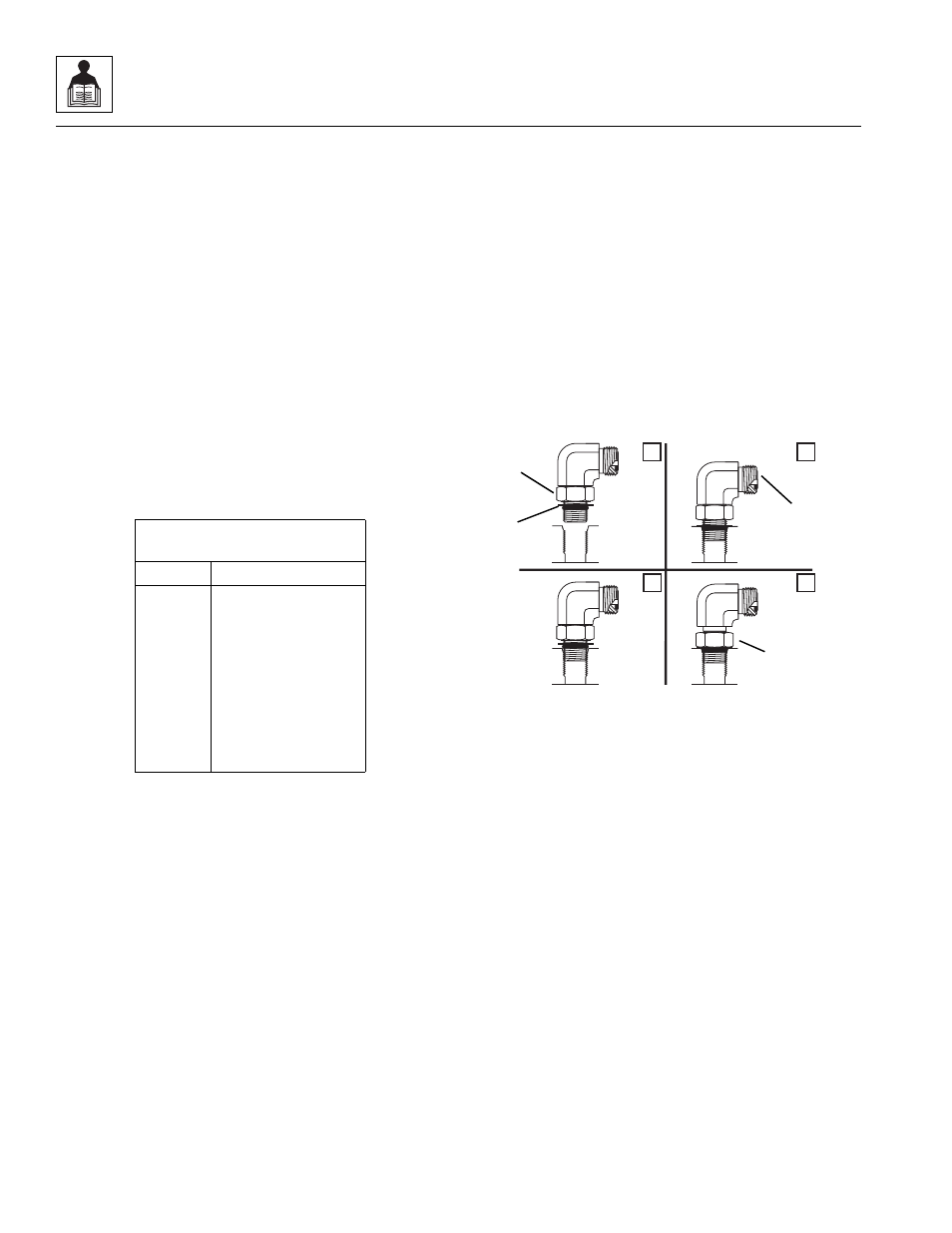

c. Adjustable (Angle) O-Ring Boss Fittings To

O-Ring Boss Ports

Improper assembly of this joint will result in a leaking joint.

Failure to position the locknut properly will result in

damage to the o-ring. Under tightening of the fitting will

result in the fitting loosening during normal operation and

the joint leaking. Damaging the o-ring during assembly

will result in immediate joint leakage.

1. Inspect components to ensure that male and female

port threads and sealing surfaces are free of burrs,

nicks, or scratches, or any foreign material. If any

damage is found the bad part must not be used.

Clean any foreign material from the mating parts

before assembly.

2. Back off the locknut as far as possible (1). Make sure

the back-up washer is not loose. If the back-up

washer is loose the fitting must be rejected.

3. Lubricate the o-ring (2) and male thread with clean

petroleum based lubricant.

4. Screw the fitting into the port as far as possible by

hand (B & C).

5. To align the tube end (3) of the fitting to accept the

mating tube or hose, unscrew the fitting as required

but not more than one turn.

6. Using two wrenches, hold the fitting in the desired

position and tighten the locknut (4) to the appropriate

torque value listed in the table in Section 2.3.3, b.

“Straight O-Ring Boss Fittings To

O-Ring Boss Ports.”

O-Ring Boss Fittings To

O-Ring Boss Ports

SAE Size

Torque lb-ft (Nm)

4

15 ± 1 (20 ± 1)

6

25 ± 1 (34 ± 1)

8

55 ± 5 (75 ± 7)

10

76 ± 5 (103 ± 7)

12

130 ± 5 (176 ± 7)

16

210± 10 (285 ± 14)

20

245 ± 35 (332 ± 47)

24

315 ± 45 (427 ± 61)

A

B

C

D

MA10,0820

1

2

3

4