7a.12.3 coupler and drive shaft installation, 7a.12.3, Coupler and drive shaft installation a.40 – SkyTrak 8042 Service Manual User Manual

Page 363

Engine: Cummins 4BT3.9 and 4BTA3.9

7A.40

Model 8042, 10042, 10054 Legacy

Rev. 10/03

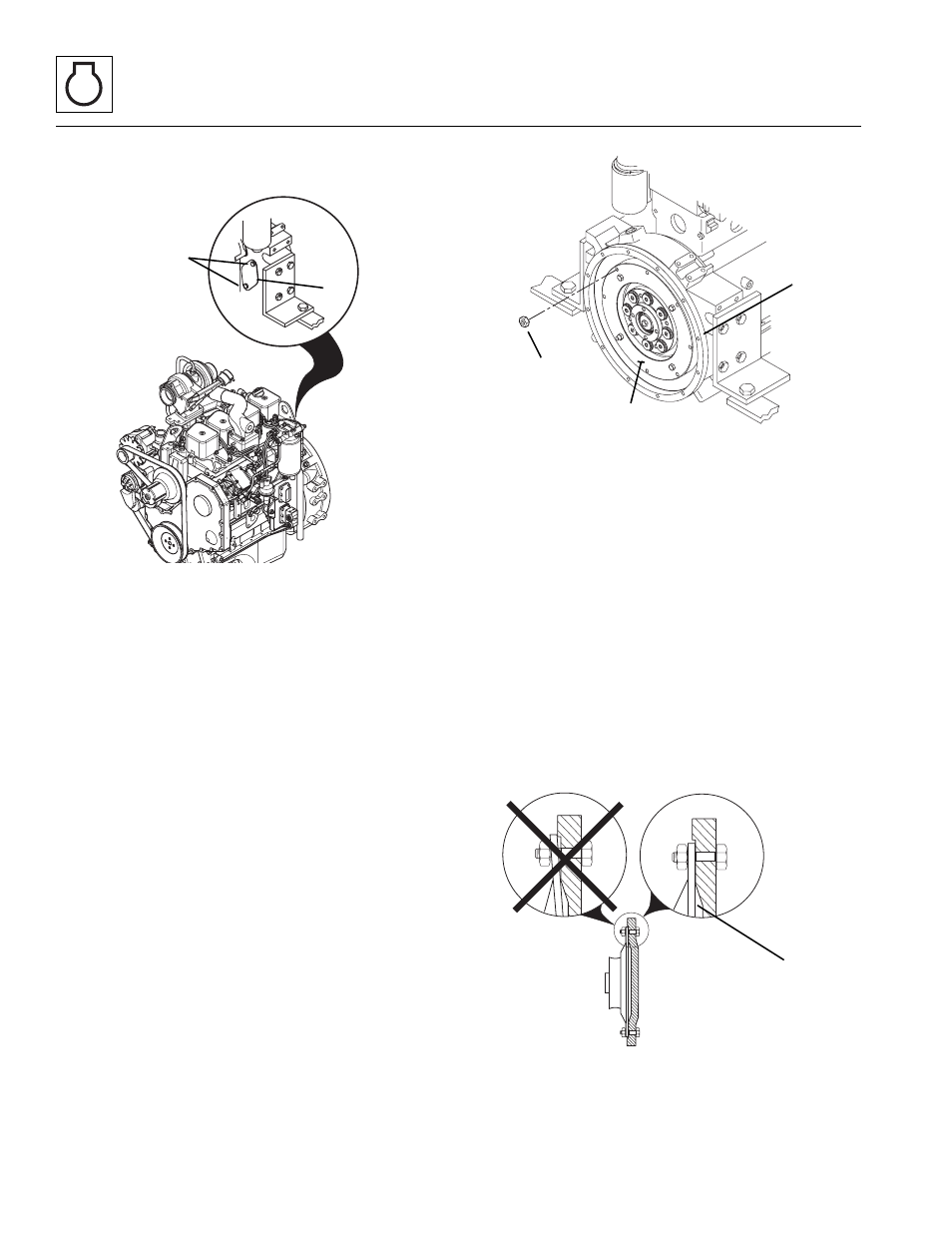

4. Remove the capscrews (1) securing the small

access cover (2).

5. Remove the capscrews and locknuts (3) securing

the coupler (4) to the flywheel. Turn the engine by

hand, using the fan belt, until the capscrews line up

with the access hole (2).

6. At this time, use a suitable cleaner/solvent and

thoroughly clean the mounting lip of the flywheel.

Wipe any debris from the inside of the bell housing.

Use the cleaner to clean the threaded holes (5)

around the flange of the bell housing.

7A.12.3

Coupler and Drive Shaft Installation

1. Use cleaner to clean the backside of the coupler,

where it comes in contact with the flywheel.

Note: The new coupler weighs approximately

56 lbs (25,4 kg) and requires two people, one on each

side, to install.

Note: ALWAYS replace elastic locknuts with new elastic

locknuts to help ensure proper fastening.

2. Place the new coupler (4) into the indentation of the

flywheel and use new Grade 8 capscrews and

locknuts (3) to secure the coupler to the flywheel.

3. Insert one capscrew into the access hole (2) on the

rear right side of the bell housing and through the

flywheel and coupler. Assemble a new elastic

locknut onto the capscrew. DO NOT fully tighten at

this time.

4. Turn the flywheel 180° and insert another capscrew

and assemble with another new elastic locknut.

DO NOT fully tighten until all of the capscrews and

locknuts are in place.

5. After all the capscrews are in place, check to be sure

the coupler is resting squarely in the indentation of

the flywheel (6). Torque all the capscrews to 37 lb-ft

(48 Nm).

6. Install the small access cover plate (2), to the right

side of the engine and tighten the hardware securely.

SH3060

1

2

SH3070

3

4

5

SH1100

6