5 liquid handling – schematic process, 1 port definitions of the dosing unit, 2 pipetting equipment – Metrohm 840 PC Control 5.0 / Touch Control User Manual

Page 328

6.5 Liquid handling – schematic process

316

PC Control / Touch Control

6.5 Liquid handling – schematic process

6.5.1 Port definitions of the dosing unit

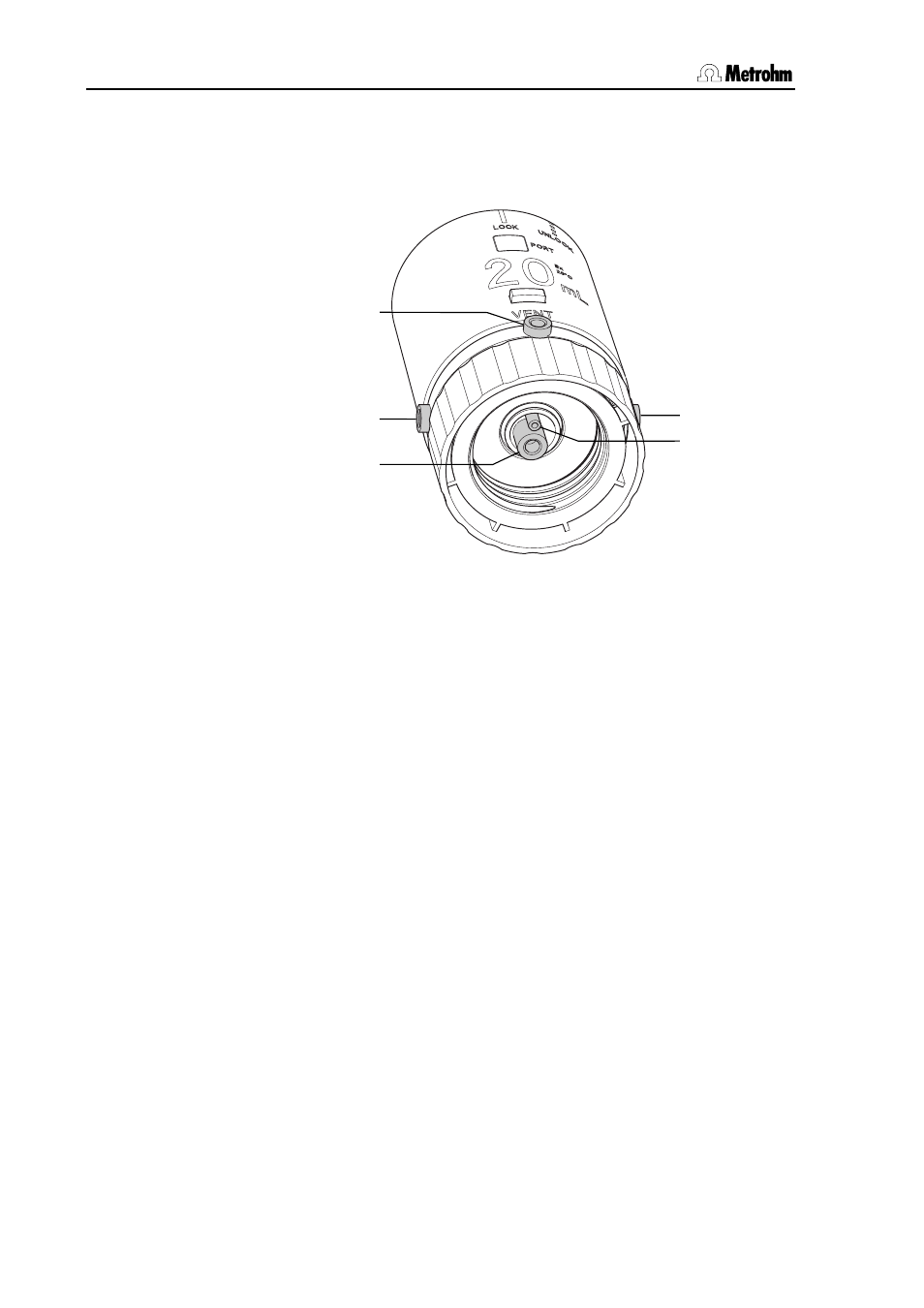

VENT

Port 1

Port 2

Port 4

Port 3

Fig. 6.5: Port occupancy of the Dosing unit

VENT – is intended for venting the storage bottle and is normally fit-

ted with an adsorber tube (filled with a drying agent).

Port 1 – is side-mounted; its default definition is as dosing port 1.

Port 2 – is located at the base; its default definition is as filling port

and it is normally fitted with a riser tube.

Port 3 – is side-mounted; its default definition is as dosing port 2.

Port 4 – is located at the base; its default definition is as air inlet port

for emptying the tubing system.

6.5.2 Pipetting

equipment

Together with an 800 Dosino as the dosing drive (or "pipetting pump")

the USB Sample Processor is exceedingly suitable for pipetting liquids

in a volume range between 0.1 and 10 mL.

Necessary equipment

• USB Sample Processor with 786 Swing Head

• Swing Head with transfer head (e. g. 6.1462.030 or 6.1462.040)

• 800 Dosino with 2 mL, 5 mL, 10 mL or 20 mL dosing unit

• 6.1562.020 Pipetting tubing (3 mL) or 6.1562.100 (10 mL) with

drawn-out tip

• Any sample rack

• Possibly 6.2001.070 Support Stand with titration cell