Rockwell Automation 2094-xMxx-S Kinetix 6000 Multi-axis Servo Drives User Manual User Manual

Page 35

Rockwell Automation Publication 2094-UM001H-EN-P - June 2013

35

Planning the Kinetix 6000 Drive System Installation

Chapter 2

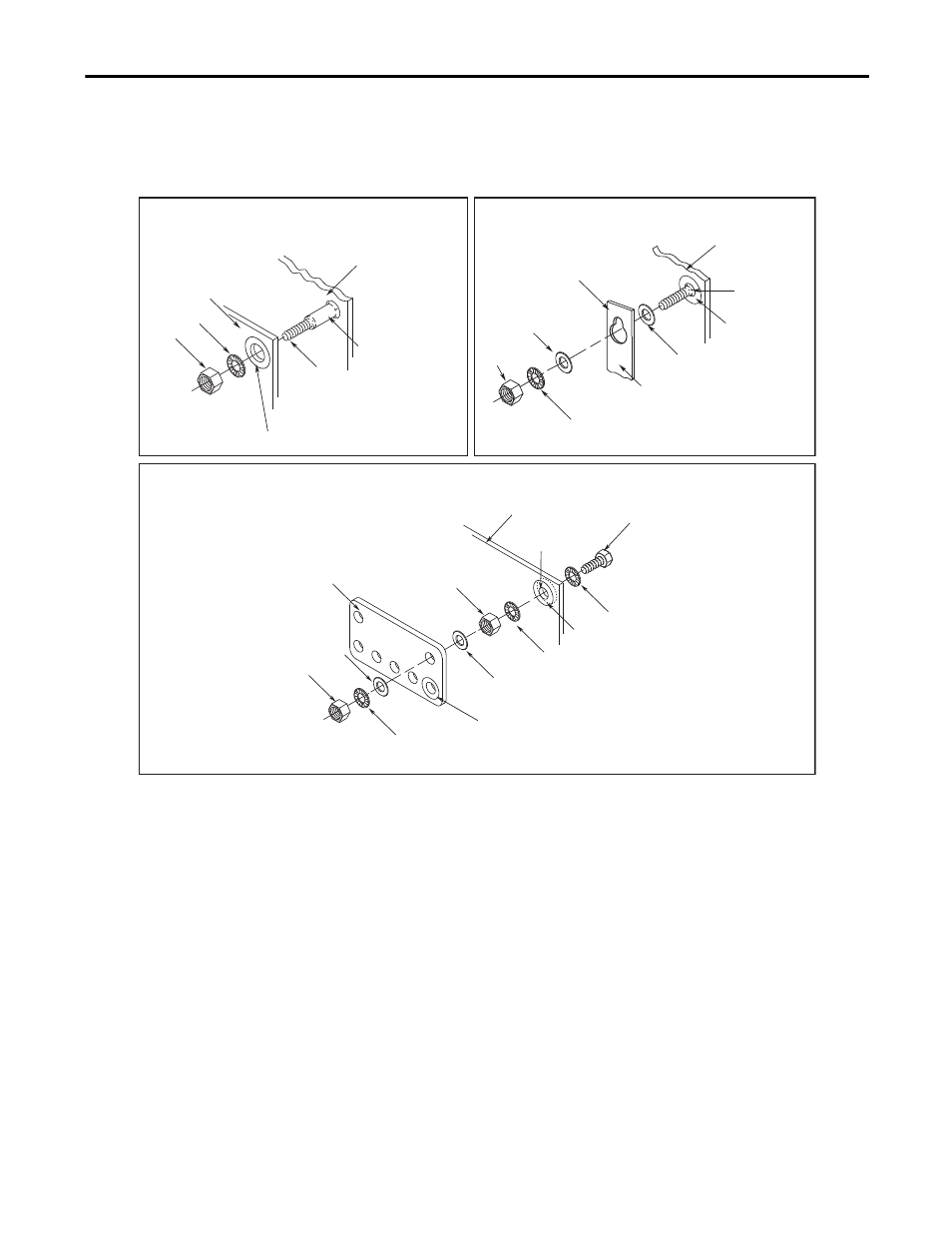

These illustrations show details of recommended bonding practices for painted

panels, enclosures, and mounting brackets.

Figure 8 - Recommended Bonding Practices for Painted Panels

Stud-mounting the Subpanel

to the Enclosure Back Wall

Stud-mounting a Ground Bus

or Chassis to the Subpanel

Subpanel

Welded Stud

Scrape Paint

Flat Washer

If the mounting bracket is coated with

a non-conductive material (anodized

or painted), scrape the material around

the mounting hole.

Star Washer

Nut

Nut

Flat Washer

Mounting Bracket or

Ground Bus

Use a wire brush to remove paint from

threads to maximize ground connection.

Back Wall of

Enclosure

Welded Stud

Subpanel

Star Washer

Use plated panels or scrape paint on

front of panel.

Subpanel

Nut

Nut

Star Washer

Flat Washer

Star Washer

Star Washer

Scrape paint on both sides of

panel and use star washers.

Tapped Hole

Bolt

Flat Washer

Ground Bus or

Mounting Bracket

If the mounting bracket is coated with

a non-conductive material (anodized

or painted), scrape the material around

the mounting hole.

Bolt-mounting a Ground Bus or Chassis to the Back-panel