Rockwell Automation 2094-xMxx-S Kinetix 6000 Multi-axis Servo Drives User Manual User Manual

Page 166

166

Rockwell Automation Publication 2094-UM001H-EN-P - June 2013

Chapter 7

Troubleshooting the Kinetix 6000 Drive System

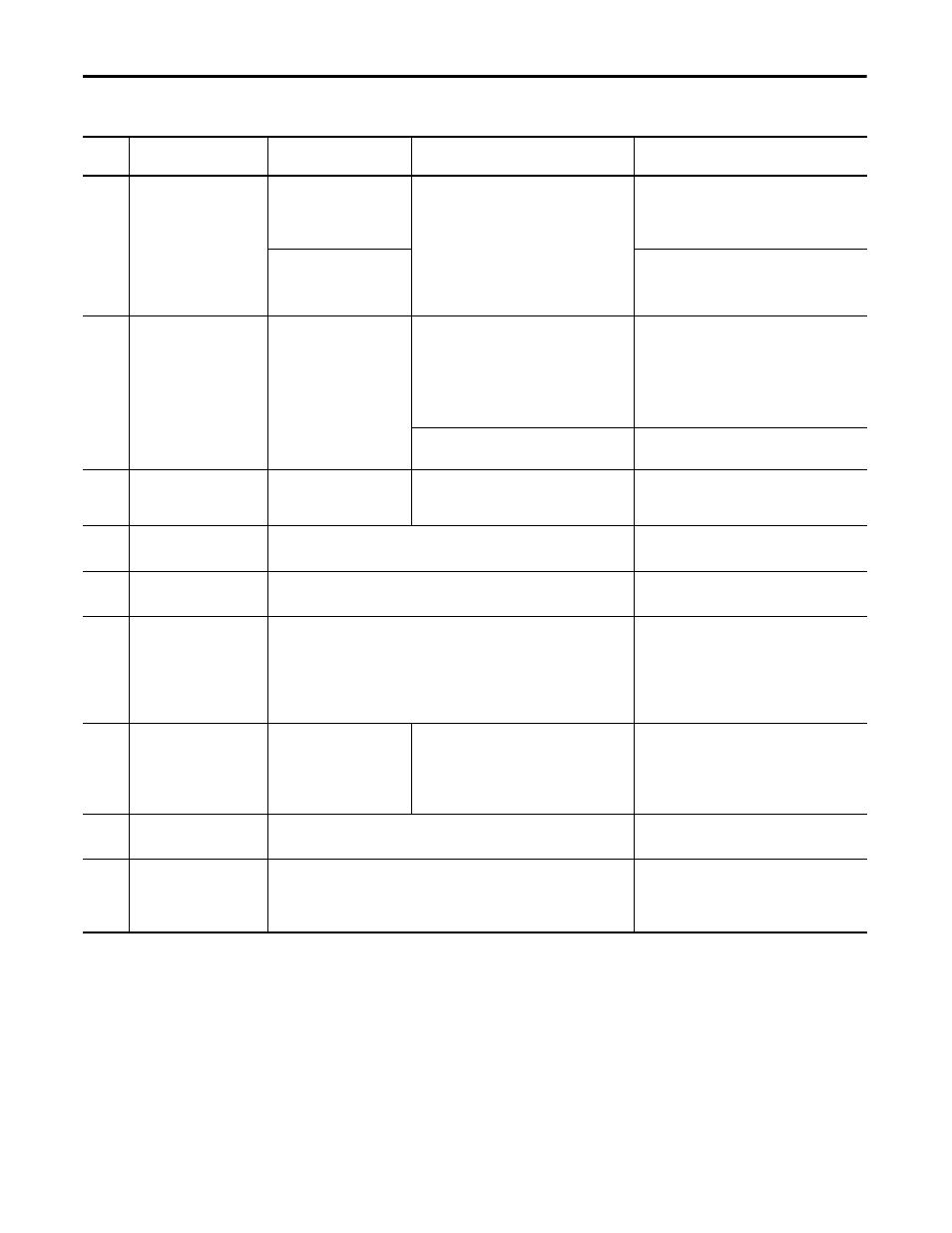

E09

BusUndervoltage Fault

(Bus Undervoltage)

With three-phase power

present, the DC bus voltage is

below limits.

• DC bus voltage for 460V system is below 275V

• DC bus voltage for 230V system is below 137V

• Verify voltage level of the incoming AC power.

• Check AC power source for glitches or line drop.

• Install an uninterruptible power supply (UPS) on

your AC input.

DC bus voltage fell below the

undervoltage limit while an

axis on the follower power rail

was enabled.

Disable follower axis before removing power.

E10

DriveOvervoltage Fault

(Bus Overvoltage)

The DC bus voltage is above

limits.

Excessive regeneration of power.

When the motor is driven by an external

mechanical power source, it can regenerate too

much peak energy through the drive power

supply. The system faults to save itself from an

overload.

• Change the deceleration or motion profile.

• Use a larger system (motor and Kinetix 6000

drive).

• Install shunt module.

• DC bus voltage for 460V system is over 820V

• DC bus voltage for 230V system is over 410V

Verify input is within specifications.

E11

MotFeedbackFault

(Illegal Hall State)

State of Hall feedback inputs is

incorrect.

Improper connections.

• Verify the Hall wiring at the MF connector on the

IAM/AM module.

• Verify 5V power supply to the encoder.

E16

Softovertravel Fault

(+/- Software Overtravel)

Axis position exceeded maximum software setting.

• Verify motion profile.

• Verify overtravel settings are appropriate.

E18

OverSpeedFault

(Overspeed Fault)

Motor speed has exceeded 150% of maximum rated speed. The 100% trip point is

dictated by the lesser of the user velocity limits or the motor rated base speed.

• Check cables for noise.

• Check tuning.

E19

PositionErrorFault

(Follow Error)

Position error limit was exceeded.

• Increase the feed forward gain.

• Increase following error limit or time.

• Check position loop tuning.

• Verify sizing of system.

• Verify mechanical integrity of system within

specification limits.

E20

MotFeedbackFault

(Mtr Fdbk AQB)

Motor Encoder State Error

The motor encoder encountered an illegal

transition.

• Use shielded cables with twisted pair wires.

• Route the feedback away from potential noise

sources.

• Check the system grounds.

• Replace the motor/encoder.

E21

AuxFeedbackFault

(Aux Feedback Comm)

Communication was not established with an intelligent encoder.

Verify auxiliary encoder wiring.

E30

MotFeedbackFault

(Motor Feedback Comm)

Communication was not established with an intelligent encoder.

• Verify motor selection.

• Verify the motor supports automatic

identification.

• Verify motor encoder wiring.

Table 99 - Seven-segment Status Indicator Error Codes (continued)

Error

Code

Fault Message - Logix

Designer (HIM)

Anomaly or Symptom

Potential Cause

Possible Resolution