Table 3-1. sampling time intervals, 8 datalink – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 87

If the BACKGROUND SCAN INDEX is left at one, the display will be updated with each control

algorithm execution because it will be determined solely by the SCAN INDEX. A number greater than

one configured into the BACKGROUND SCAN INDEX causes that many control algorithm updates to

occur before the display is updated with new data.

There is a standard display algorithm for each display of the 53MC5000 Process Control Station.

(The controller displays are covered in detail in Section 4.) If the controller has

extended function-

ality (model number 53MC5

♦♦

2 etc., where

♦

is a selectable item), F-TRAN can be used to create

personalized display algorithms to supplement the standard display complement. The display is

generated when the microprocessor interprets the active display algorithm to produce a pattern in

memory which corresponds to the elements in the display. This pattern is then transferred into a

special memory which can be accessed by two processors. Here a second processor uses the

contents of the memory to light individual elements in the display. The dynamics of the display

require that each element be on only a fraction of a second. Therefore, to give the appearance of

being continuously lit, the second processor refreshes the screen by turning the individual elements

on and off 80 times a second.

The horizontal and vertical keypads are scanned 20 times a second (every 50 ms). When a key is

detected as being pressed, that information is temporarily stored for synchronization with the control

algorithms and display processing. If a slewing key is pressed (setpoint up arrow, etc.), the

appropriate database location is manipulated. For controllers with multiple loops, e.g., 2 loop or 4

loop controllers, a pointer appears on the display to identify which algorithm is affected by the keypad

push buttons. The pointer directs the keypad inputs to the individual control algorithm databases.

The pointer is shifted from one loop to another with a push button on the vertical keypad.

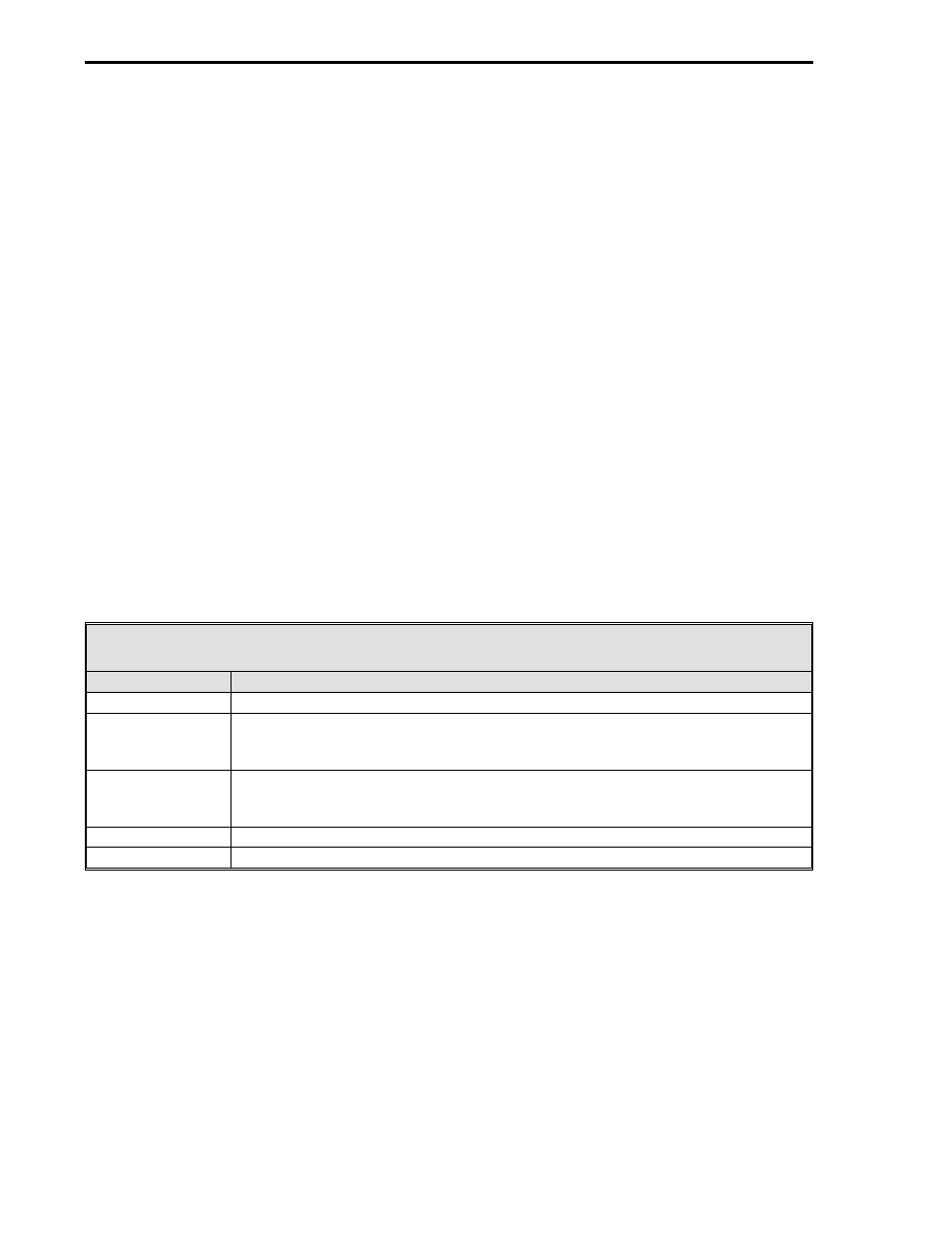

A summary of the sampling time intervals is provided in Table 3-1 as follows:

Table 3-1. Sampling Time Intervals

Time Interval

Event

50 ms

Analog and digital input signal sampling.

50 ms - 1500 ms

Input signals are digitally processed through user selected algorithms (50 ms =

1/20 s = SCAN INDEX set to 1. 1500 ms = 1 1/2 seconds = SCAN INDEX set

to 30).

1 s

Time between successive trend and totalizer updates. Each trend and each

totalizer is updated sequentially in ascending order every 50 ms. Trends are

updated first, then totalizers.

80 times/s

Display elements are turned on and off to refresh the screen.

50 ms

Keypads are scanned.

3.8 DATALINK

The Datalink port is at the rear of the unit on either the Standard Rear Terminal Board (pins 19

through 22) or the optional Cord Set Connector Board (J10 and J11). It provides the standard

RS-485 MICRO-DCI multidrop network connection. A personal computer with the appropriate soft-

ware application package loaded and running (see the table of software application packages in

Section 3.2) can function as the network server and therefore be a central operating station for the

network. The maximum data transfer rate for a Datalink network is 28,800 baud.

53MC5000 Process Control Station

3-4