Table 5-9. controller modules (con0-3) – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 166

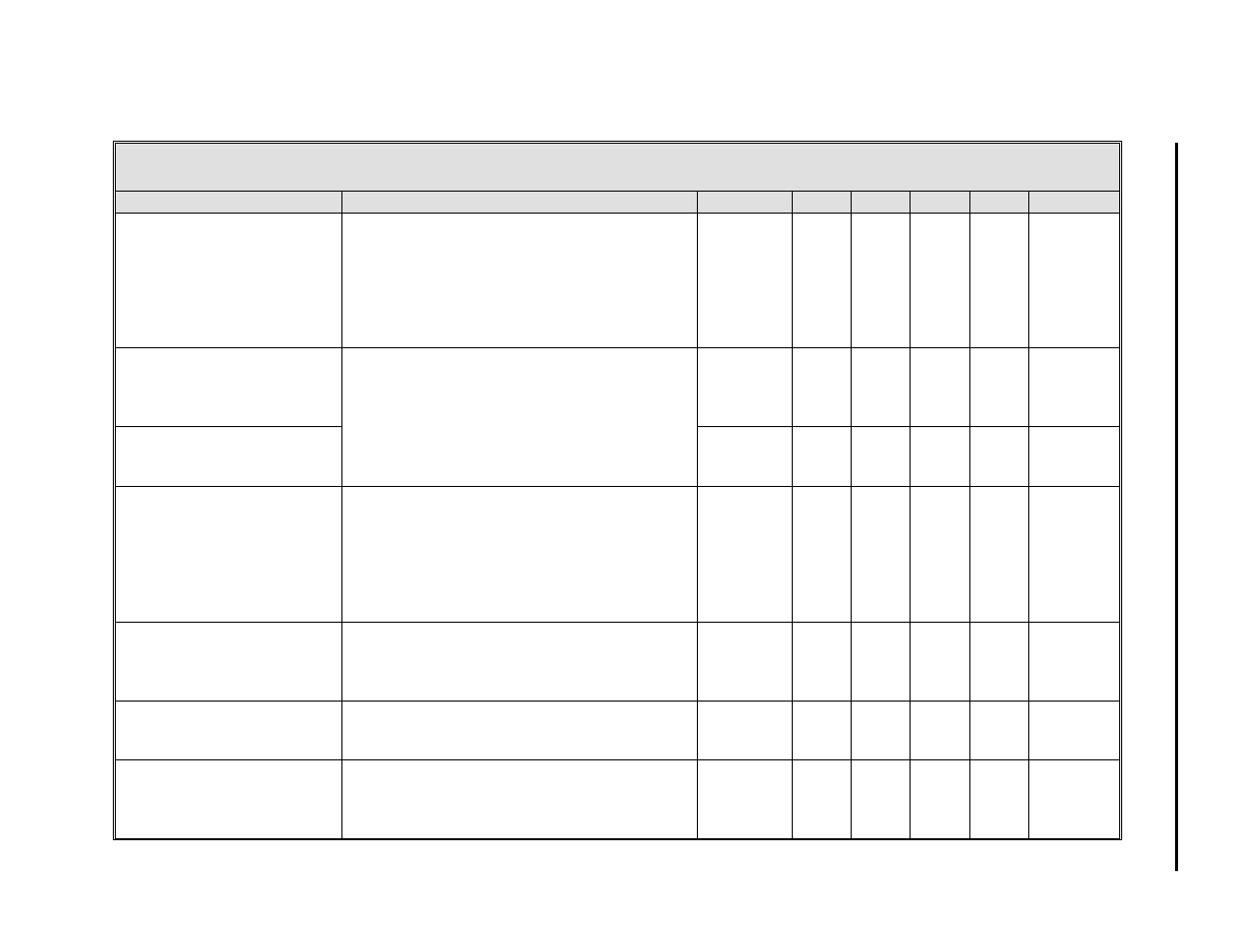

Table 5-9. Controller Modules (CON0-3)

Title

Definition

Atom

CON0

CON1

CON2

CON3

Default

Control Zone

This parameter defines a gap or dead band on

either side of the setpoint. When the process

variable is within this gap, proportional and

integral output changes are suppressed.

Note

that derivative changes are based on the PV

and are therefore not affected.

CZ

(0-3)

C114

C150

C186

C222

0

Controller Span

These two parameters set the upper and lower

values on the controller display. They permit

the control action to be defined over a range

independent of the process variable input

range. They also determine the speed at which

the setpoint changes when the up or down

arrow push buttons are pressed.

IR (0-3)

C115

C151

C187

C223

100

Controller Lower Range

ILR (0-3)

C116

C152

C188

C224

0

Setpoint Slew Rate

This parameter imposes a ramp limit on the

setpoint. When configured to a non-zero

value, the setpoint used in the PID algorithm is

allowed to change each scan time only by the

amount configured. The final value of the

setpoint is always displayed on the units

display.

T1

(0-3)

C117

C153

C189

C225

0

Output Slew Rate

This value is the maximum output change in

percent allowed for the PID algorithm. A zero

disables output slewing. This value has no

effect on the manual operation of the output.

T3

(0-3)

C118

C154

C190

C226

0

Control Setpoint

The setpoint value that has setpoint slewing

applied and is used internally to calculate the

deviation for the PID function.

TSP

(0-3)

C119

C155

C191

C227

0

Remote Setpoint

The value used to determine the setpoint when

Remote Status (RMT) is a

1 and Setpoint

Track Status (SPTS) is a

0.

SP = [RSP x K1] + B1

RSP

(0-3)

C120

C156

C192

C228

0

8 of 9

5-

2

1

Se

ctio

n 5.

Co

nf

igu

rat

ion

Pa

ra

m

e

te

rs