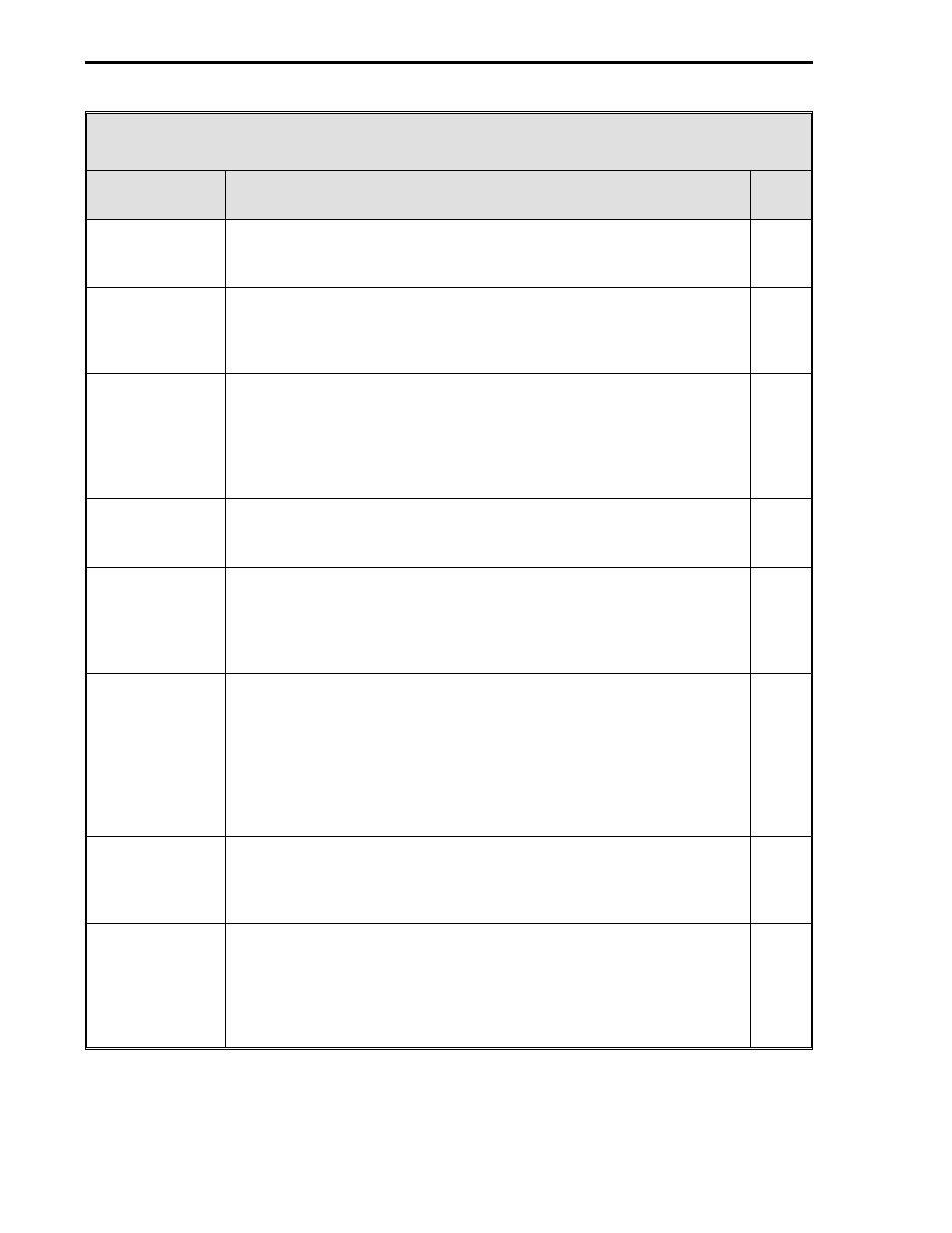

Table 5-3. database modules – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 149

Table 5-3. Database Modules

Name

Purpose

See

Table

Discrete Out

Modules

These modules allow the action of a DOs to be reversed (normally a

closed contact = 1, but can be changed to = 0). The 18 Contact

Closure Output (DO0-17) Modules can be configured separately.

5-7

External

Module

This module provides the ability to transfer data to/from other MICRO-

DCI controllers or instruments through the MicroLink peer-to-peer

communications network. It provides 24 (0-23) tasks, each capable of

performing a read, write, or bidirectional operation.

5-8

Control

Modules

The primary purpose of these modules are to affect the action of the

control algorithms and the content of the control loop displays. They

are used to set the controller’s responsiveness, Alarm Limits 1 & 2,

Alarm Dead Band, and the range limits (e.g., 0 - 100, -20 - 80.), etc.

There are four Controller Modules (CON0-3) that can be configured

separately, one for each control loop display.

5-9

Status

Modules

There are two Status Modules that can be configured separately.

Each module displays eight logical status indicators that can also

generate alarms when enabled.

5-10

Parameter

Modules

These modules provide quick push button display access to any three

selected datapoints for viewing or modifying (e.g., Alarm Limits 1 & 2

and Alarm Dead Band) without the necessity of entering Engineer

mode and addressing the datapoints. There are eight Parameter

Display Modules that can be configured separately.

5-11

Trend Modules

There are eight Trend Modules that can be configured separately.

Each Trend Module provides storage of the last 80 samples of the

specified input. The first four Trend Modules can be attached to the

four CON Modules if the Trend Rate datapoint in the appropriate CON

Module is non-zero. When a Trend Module is attached to its

appropriate CON Module, height, rate, mode, span, zero, and

designator parameters are overwritten with values from the CON

Module.

5-12

Totalizer Modules There are eight totalizer modules that can be configured separately.

Each module provides a

totalization (integration) of a specified input.

Sampling occurs once a second, whenever the input parameter

contains a valid datapoint specification.

5-13

System Module

This module contains unit level parameters for controlling overall

operations as well as selecting and enabling various features. It is

used to select the desired controller operating algorithm and execute

rate, build the display list, configure Datalink, Microlink, and gateway

parameters (to configure the MicroLink and gateway parameters, see

Instruction Bulletin 53MC9011, Revision 2, MicroLink.)

5-14

2 of 2

53MC5000 Process Control Station

5-4