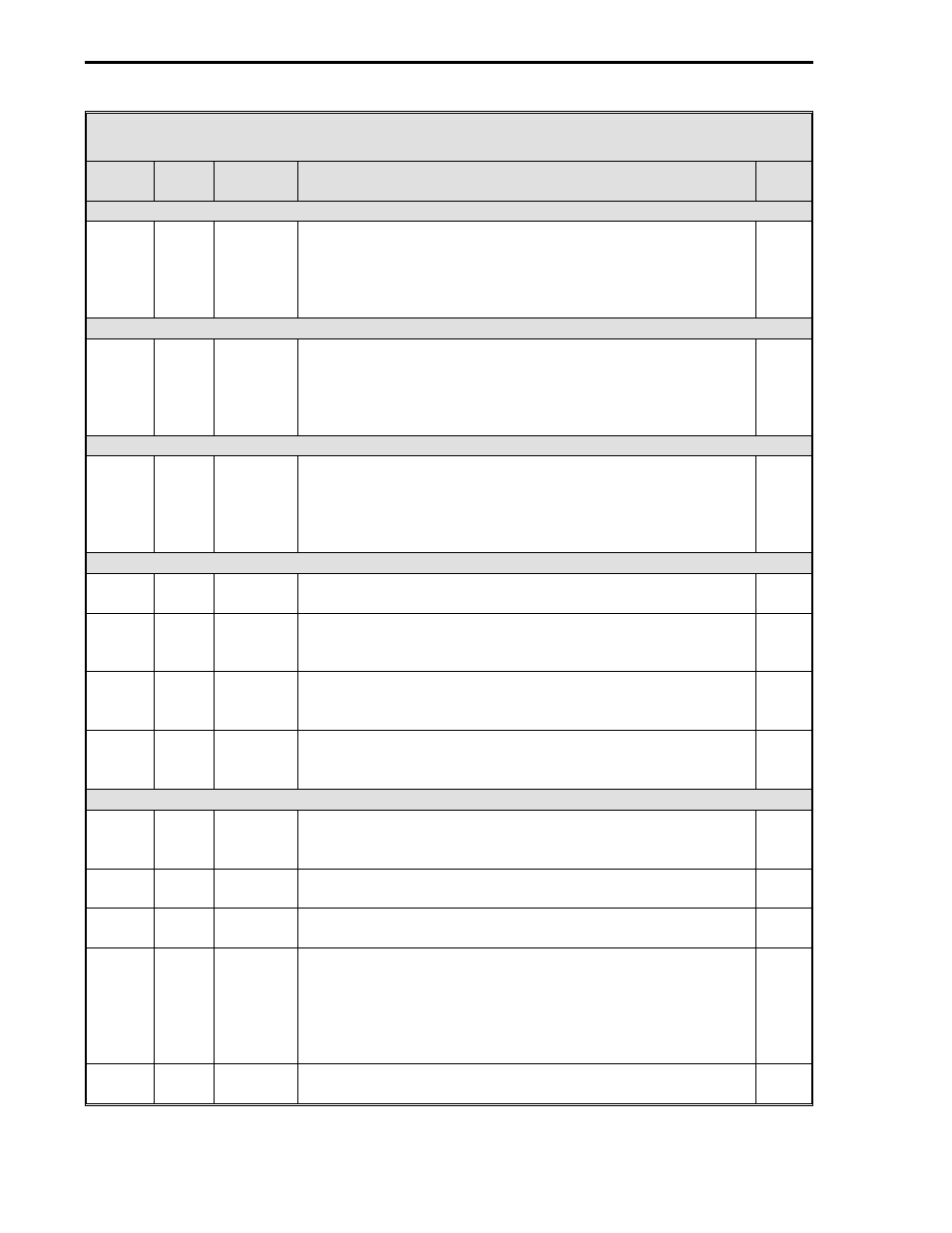

Table 6-3. cs1 single loop con0 datapoints – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 193

Table 6-3. CS1 Single Loop CON0 Datapoints

Data-

point

Table

Module

Title and Function

De-

fault

DI1 - Remote Setpoint Enable

L265

5-6

DI1

Contact Input Invert - Normally, Remote Setpoint Enable is

permitted if DI1 is closed (datapoint L115 - Remote Setpoint

Enable is set to 1 by DI1). Set to 1 to reverse the DI1

condition required to activate remote setpoint (DI1 open =

Remote Setpoint Enable).

0

DO0 - Process Alarm 1

L288

5-7

DO0

Contact Output Invert - Normally, Process Alarm 1 is enabled

if DO0 is closed. Set to 1 to reverse the DO0 condition

required to activate Process Alarm 1 (DO0 open = the PV

value is not within the C103 limit).

0

DO1 - Process Alarm 2

L289

5-7

DO1

Output Invert - Normally, Process Alarm 2 is enabled if DO1

is closed. Set to 1 to reverse the DO1 condition required to

activate Process Alarm 2 (DO1 open = the PV value is not

within the C104 limit).

0

Alarms Related Datapoints

B335

5-9

CON0

Control Alarm Mode - Used to select one of six alarm types

or none. See Table 5-9 for details and examples.

1

C103

5-9

CON0

Alarm Limit 1 - Point in engineering units where an alarm is

triggered because the PV is not within the limit value set in

C103.

100

C104

5-9

CON0

Alarm Limit 2 - Point in engineering units where an alarm is

triggered because the PV is not within the limit value set in

C104.

0

C105

5-9

CON0

Alarm Dead Band - Sets the activation/deactivation gaps for

the alarm limit points. It is in engineering units.

2

Setpoint Related Datapoints

C114

5-9

CON0

Control Zone - A gap on both sides of setpoint. When PV is

within this gap, the proportional and integral output changes

are suppressed. Derivative output is unaffected.

0

C125

5-9

CON0

Setpoint High Limit - It is the maximum control setpoint value

allowed.

100

C126

5-9

CON0

Setpoint Low Limit - It is the minimum control setpoint value

allowed.

0

C117

5-9

CON0

Setpoint Slew Rate - It is a rate limit applied to the setpoint.

When configured to a non-zero value, the setpoint used in

the PID algorithm is only allowed to change by this amount

each scan time. The final value of the setpoint always

appears on the units display. A zero disables setpoint

slewing.

0

L118

5-9

CON0

SP Track Enable - 1 = allow setpoint to track the process

variable when in manual.

0

4 of 5

53MC5000 Process Control Station

6-8