Table 16-3. proportional cycle method, Table 16-4. step response method (ziegler-nichols) – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 300

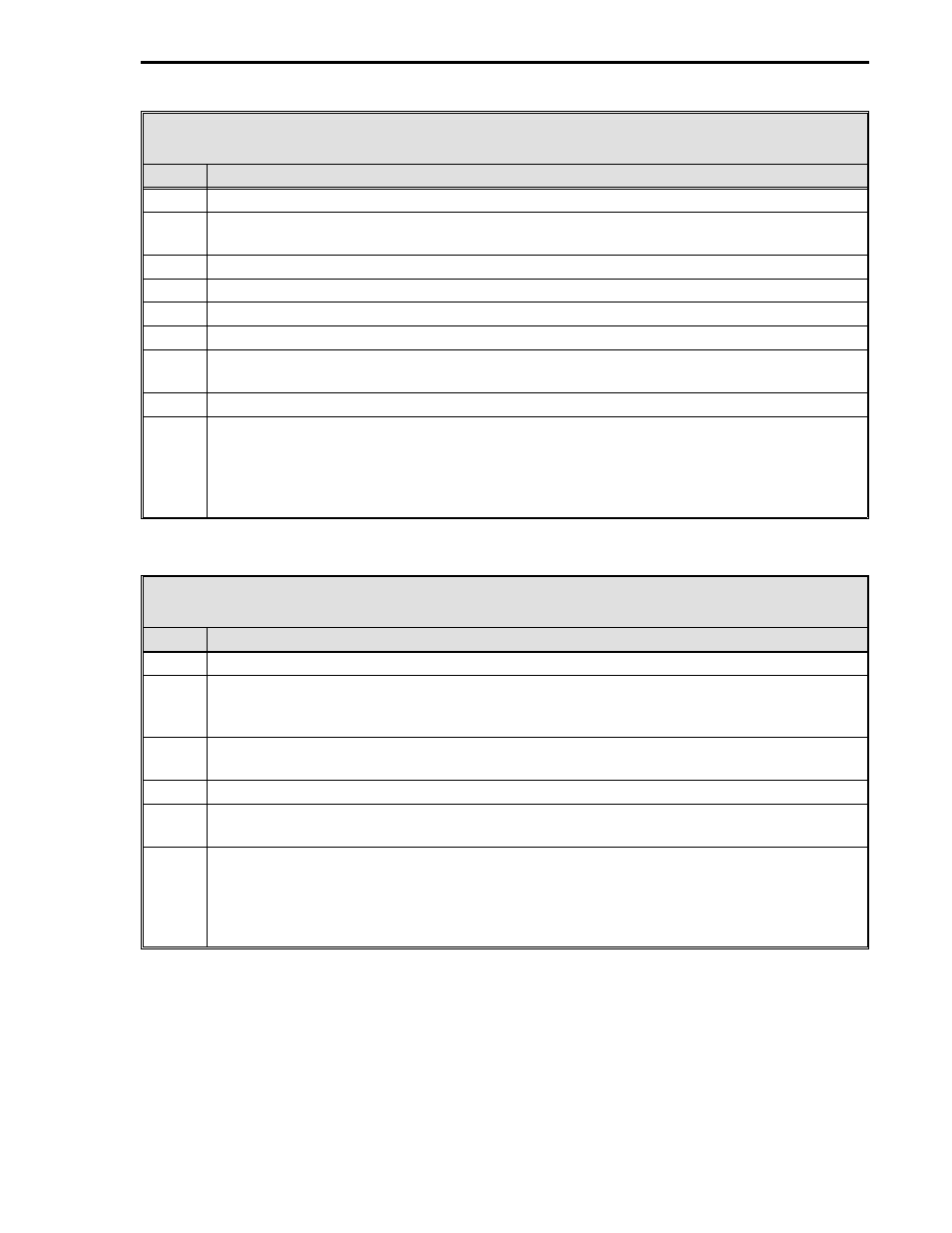

Table 16-3. Proportional Cycle Method

Step

Procedure

1

Set the process to approximately normal conditions in

Manual mode.

2

Set TR first to minimum value (0.02 minutes) for several moments, then set it to the

extreme maximum (200 minutes) to lock in a fixed reset value.

3

Set P.B. to the widest value (1000%).

4

Set TD to the lowest value (0.01 minutes).

5

Switch to

Auto mode..

6

Slowly reduce P.B. until process cycling starts.

7

When a slight cycle is repeatedly established, measure the peak-to-peak period of

oscillation and record it as

T minutes.

8

Observe the P.B. setting and record it as

P.

9

Compute the best settings as follows:

A. Proportional & Integral (PI): P.B. = 2 (P), TR = 0.8(T)

B. Proportional & Derivative (PD): P.B. = 0.8(P), TD = 0.12(T)

C. Proportional, Integral, and Derivative (PID): P.B. = 1.5(P), TR = 0.5(T),

TD = 0.12(T)

Table 16-4. Step Response Method (Ziegler-Nichols)

Step

Procedure (Reference Figure 16-1.)

1

Set the process to approximately normal conditions in

Manual mode.

2

Introduce a 10% (approximate) step change to the manually regulated signal to the

valve. Observe the magnitude of the step in percent of full signal span

F . Also plot a

graph of the resulting transient curve traced by the controlled variable.

3

Draw a straight line tangent to a point on the curve having the greatest slope (most

linear).

4

Measure the apparent dead time

L in minutes as shown in Figure 16-1.

5

Measure

RL, the product of the slope and dead time as shown in Figure 16-1. This

value should be expressed in percent of full scale span.

6

Compute the best settings as follows:

A. Proportional (P): P.B. = (100 RL) / F.

B. Proportional & Integral (PI): P.B. = (100 RL) / F, TR = 3L

C. Proportional, Integral, and Derivative (PID): P.B. = (80 RL) / F, TR = 2L,

TD = 0.5L.

Section 16. Tuning PID Parameters

16-3