Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 271

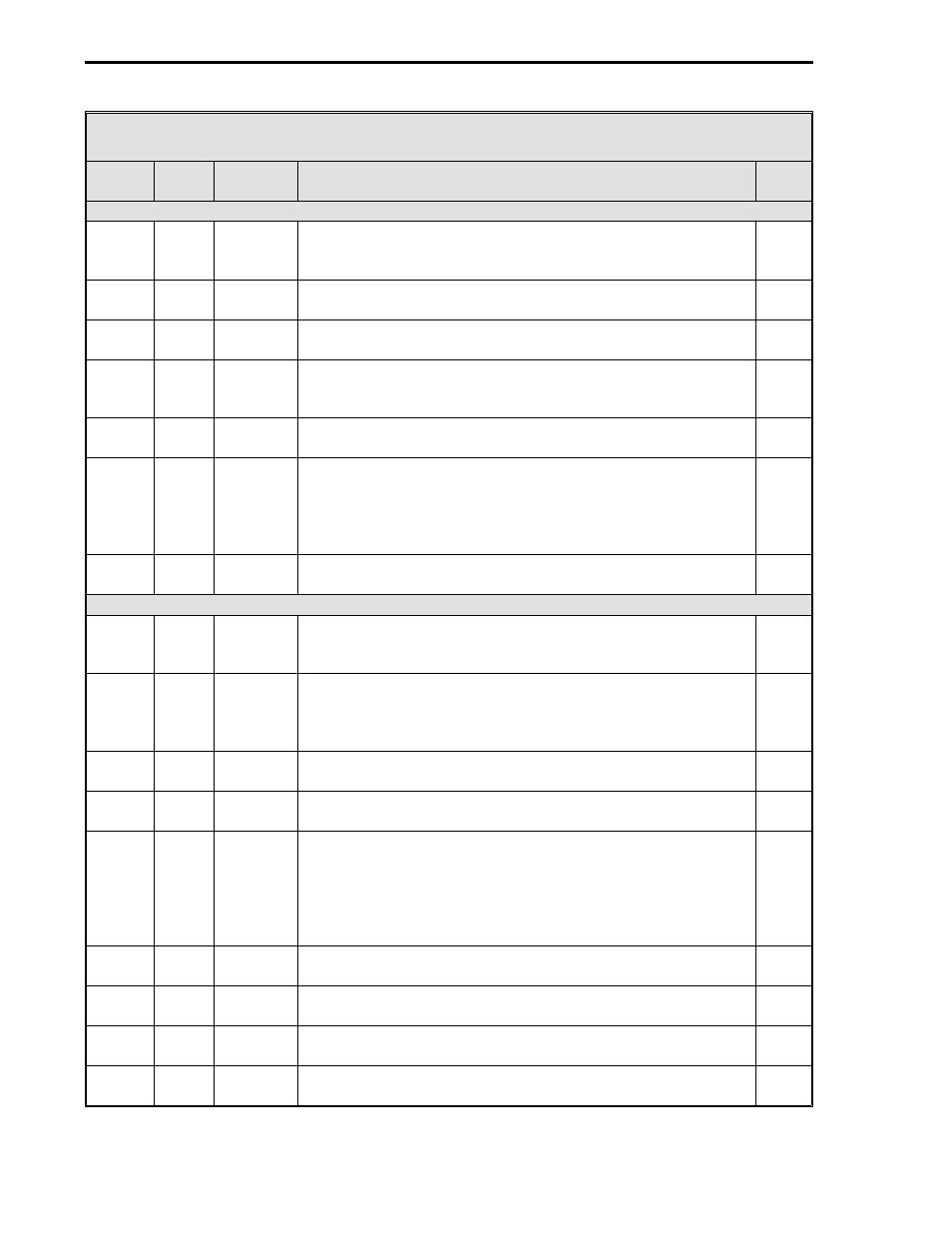

Table 14-3. CS40 Dual Two Loop Cascade Controller Datapoints

Data-

point

Table

Module

Title and Function

De-

fault

CON 2 #1 Secondary Control Output (LOOP 3) Related Datapoints (Cont)

C183

5-9

CON2

Manual Reset - It determines output valve position when the

controller Loop 3 is in Auto and the error = 0. It is mutually

exclusive with Reset Time.

50

L154

5-9

CON2

Reverse Switch - 0 = Loop 3 output

↑

if PV

↑

; 1 = Loop 3

output

↓

if PV

↑

.

1

L162

5-9

CON2

Auto Enable - Output is from the PID algorithm when set to 1

and the A/M push button is in Auto.

1

C187

5-9

CON2

Controller Span - Enter a value, that when added to the Loop

3 Control Lower Range value, will produce the Control upper

range value in engineering units.

100

C188

5-9

CON2

Controller Lower Range - Enter a value that represents in

engineering units the Loop 3 Control lower range value.

0

C184

5-9

CON2

Remote Setpoint Bias (B1) - This datapoint and Remote

Setpoint Ratio (K1) allow the CON0

•

OUT to be modified by

the CON2 Setpoint Generator.

Secondary Setpoint = [CON0

•

OUT X Ratio] + Bias

Secondary SP = [CON0

•

OUT X K1] + B1

0

C185

5-9

CON2

Remote Setpoint Ratio (K1) - See Remote Setpoint Bias (B1)

above.

1

CON1

•

OUT (Setpoint from Loop 2 to Loop 4)

L144

5-9

CON1

Manual Fallback Disable - 0 = always power up Loop 2 in

manual; 1 = Loop 2 auto/manual selector unchanged at

power up.

0

L146

5-9

CON1

Hard Manual Limit - 1 = apply output limits to the final output

of the Loop 2 Auto-Manual Generator. Affects both the

manual push buttons and the controller’s result. 0 = do not

apply limits.

1

C145

5-9

CON1

Output High Limit - Sets maximum CON1

•

OUT signal value

in engineering units.

100

C146

5-9

CON1

Output Low Limit - Sets minimum CON1

•

OUT signal value in

engineering units.

0

C154

5-9

CON1

Output Slew Rate - It is a rate limit applied to the output

value (setpoint from Loop 2 to Loop 4). When configured to

a non-zero value, the output from the Loop 2 Auto-Selector is

only allowed to change by this amount each scan time. A

zero disables output slewing. It does not affect manual

operation.

0

C142

5-9

CON1

Proportional Band - Is the percent of error required to move

the CON1

•

OUT full scale for proportional action.

100

C143

5-9

CON1

Reset Time - Is the number of minutes per repeat of integral

action. It is mutually exclusive with Manual Reset.

0

C144

5-9

CON1

Rate Time - Represents the minutes proportional action is

advanced.

0

L130

5-9

CON1

Reverse Switch - 0 = CON1

•

OUT

↑

if PV

↑

;

1 = CON1

•

OUT

↓

if PV

↑

.

1

4 of 7

53MC5000 Process Control Station

14-10