3 derivative action (td), 4 controller pid loop tuning, Table 16-2. trial and error tuning method – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 299

16.3 DERIVATIVE ACTION (TD)

Derivative action augments proportional action by responding to the rate of change of the process

variable. It is used to make each controller PID loop more responsive to sudden process

disturbances. The datapoints to set the Rate parameters for CON0 through CON3 are C108,

C144, C180, and C216; they each have a default value of 0 minutes. The minimum value for de-

rivative action is 0.01 minutes and the maximum value is 8 minutes; 0 is off. The derivative time in

minutes is the amount of time by which the proportional action (or proportional plus integral action)

is advanced.

16.4 CONTROLLER PID LOOP TUNING

Table 16-1 provides summary information for the tuning parameters referenced in the three tuning

methods that follow. The Trial and Error Method (Table 16-2) is usually preferred for process

loops that respond quickly, requiring no waiting to determine steady cycling process conditions.

The Proportional Cycle Method (Table 16-3) and Step Response Method (Table 16-4) are expedi-

ent procedures for slow processes. See Figure 16-1 for the Step Response Method Curve.

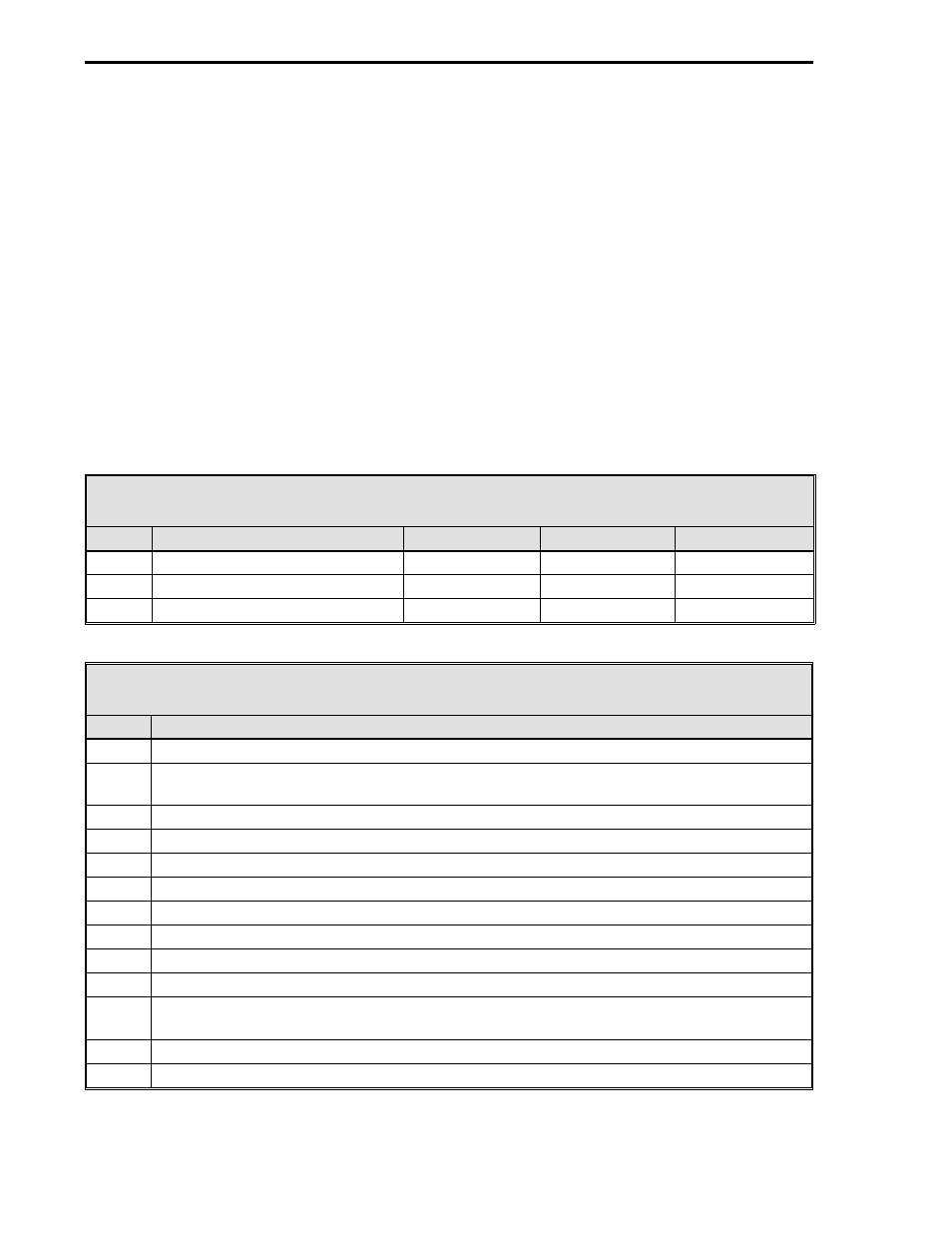

Table 16-1. Summary Information for Tuning Parameters

Abbr.

Datapoint (CON0, 1, 2, 3)

Min. Affect

Max. Affect

Parameter

P.B.

C106, C142, C178, C214

1000%

2%

Proportional Band

TR

C107, C143, C179, C215

200 min/rep.

0.02 min/rep.

Reset

TD

C108, C144, C180, C216

0.01 minutes

8 minutes

Rate

Table 16-2. Trial and Error Tuning Method

Step

Procedure

1

Set the process to approximately normal conditions in

Manual mode.

2

Set TR first to minimum value (0.02 minutes/rep.) for several moments, then set it to the

extreme maximum (200 minutes/rep.) to lock in a fixed reset value.

3

Set P.B. to the widest value (1000%).

4

Set TD to the lowest value (0.01 minutes).

5

Switch to

Auto mode..

6

Slowly reduce the P.B. value from 1000% until process cycling starts.

7

Increase TD slowly from 0.01 minutes until process cycling stops.

8

Reduce P.B. until process cycling starts again.

9

Increase TD again until cycling stops.

10

Repeat steps 8 and 9 until no improvement can be made when TD is increased.

11

Increase P.B. to a safe margin approximately 1.5 times the value attained in steps 8

through 10.

12

Introduce automatic reset slowly by decreasing TR until cycling starts.

13

Back off TR to a safe margin of about 1.5 times the value attained in step 12.

53MC5000 Process Control Station

16-2