0 cs5 - ratio automatic/manual station, 1 cs5 - ratio automatic/manual station – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 220

10.0 CS5 - RATIO AUTOMATIC/MANUAL

STATION

10.1 CS5 - RATIO AUTOMATIC/MANUAL STATION

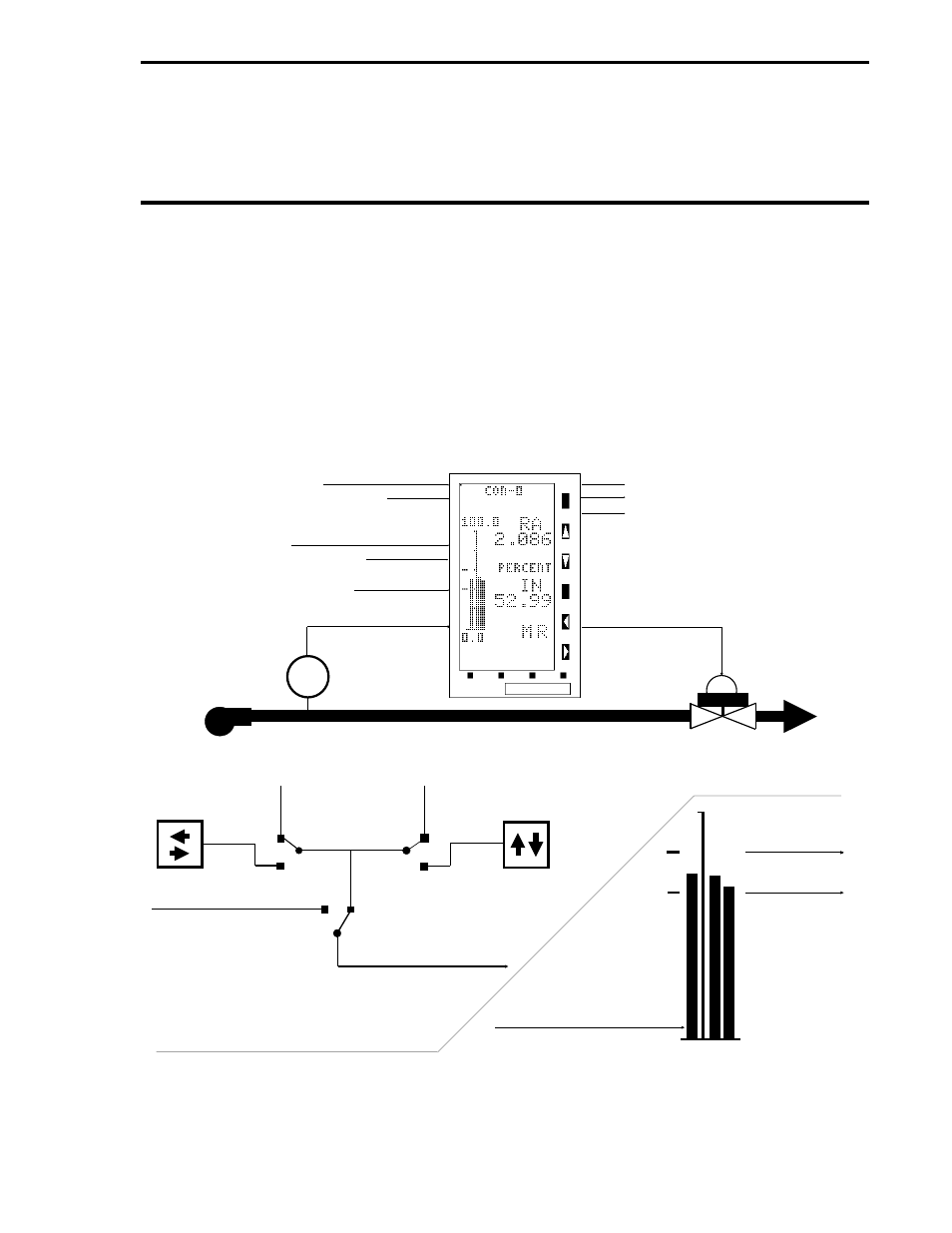

The Ratio Automatic/Manual Station operates as a combination auto/manual selector, a manual

loader, and a ratio station. Transfer from automatic to manual is bumpless after which the output

may be manipulated with the faceplate output push buttons. In automatic, the signal on AI0 is

modified by the ratio value, then passed through to the station’s output at AO0. A closed contact

on DI1 forces the value of the ratio to match AI1. When DI1 has an open contact, the ratio value is

set by the faceplate setpoint push buttons. The station’s output tracks AI3 when an open contact

appears on DI0 and output tracking is enabled (L119 = 1). The station also provides alarming

based on an independent signal, AI2. Alarm conditions are reflected by DO0 and DO1. A typical

low-resolution display Ratio Automatic/Manual Station is illustrated in Figure 10-1.

Figure 10-1. Typical CS5 Ratio Automatic/Manual Station Application

VALVE

PUMP

FT

AI3 - TRACKING INPUT

DI0 - FORCE OUTPUT TRACKING

(OPEN CONTACT)

AI0 - AUTO INPUT

DI1 - SELECT REMOTE RATIO

(CLOSED CONTACT)

AI1 - REMOTE RATIO INPUT

AI2 - ALARMED VARIABLE

AO1 - NOT USED

DO0 - PROCESS ALARM 1

DO1 - PROCESS ALARM 2

AO0 - STATION OUTPUT

AI0 - AUTO INPUT

CLOSED

DI1

OPEN

OPEN

CLOSED

DI0

MANUAL

INPUT

AI3 - TRACKING INPUT

AO0 - STATION OUTPUT

(SHOWN WITH AI0 AND AI1

DRIVING THE OUTPUT)

(L119 = 1)

(CS5 = NO PID CONTROL)

AI2 - ALARMED VARIABLE

DO0 -

PROCESS

ALARM 1

DO1 -

PROCESS

ALARM 2

(ALARM

LIMITS

SHOWN

HIGH/LOW)

A/M

A

M

AI1 - REMOTE RATIO INPUT

(K1)

SETPOINT

PUSH BUTTONS

Section 10. CS5 - Ratio Automatic/Manual Station

10-1