7 supplemental information – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller Instruction Manual User Manual

Page 322

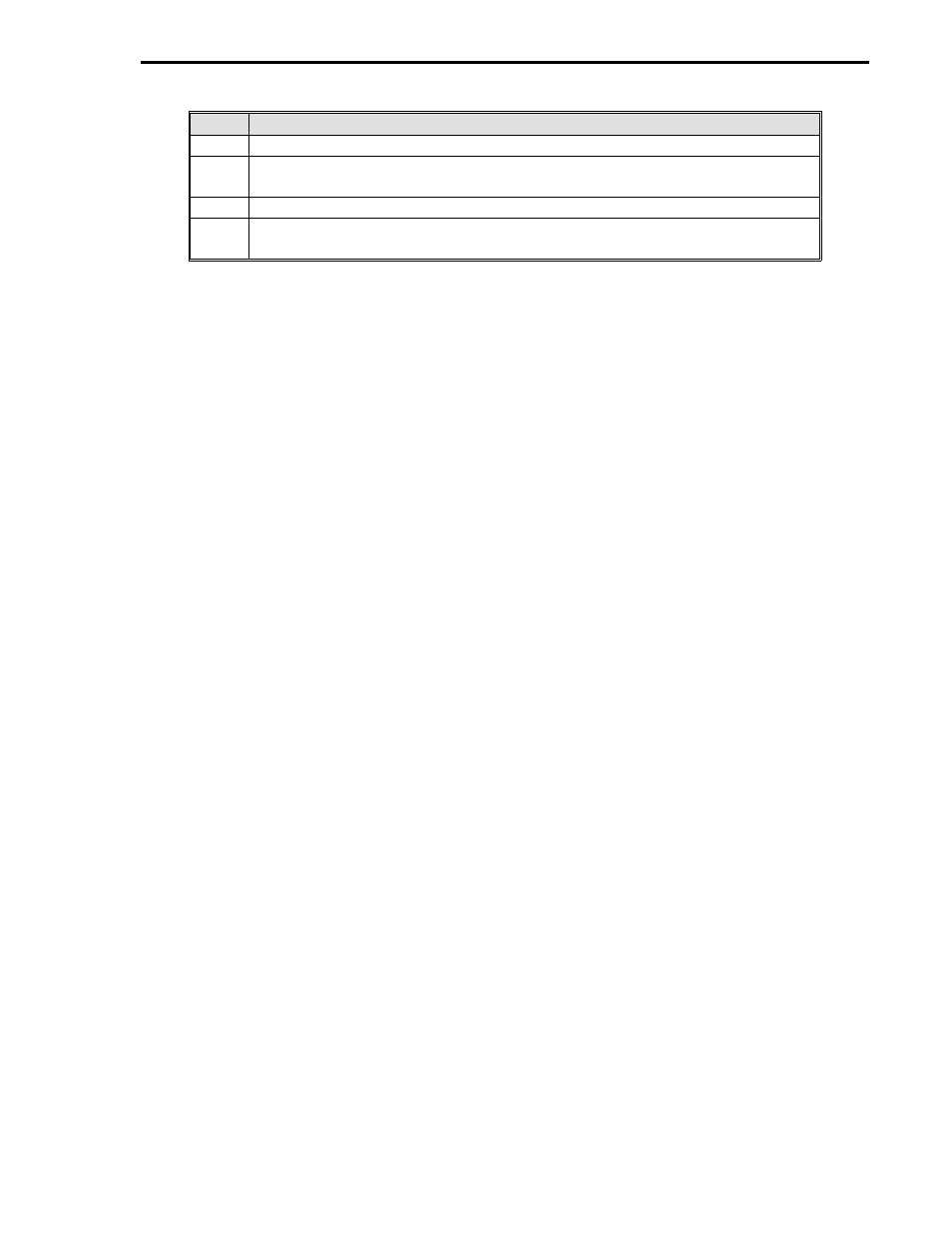

Step

Procedure

1

Press the

F2 push button and DO NOT RELEASE IT.

2

While the

F2 push button is still held pressed, use a paper clip to press the

reset button. DO NOT RELEASE the

F2 push button.

3

The display goes all black and then the default display appears.

4

Release the

F2 push button. (The database is reset to the default values with

the default display present on the controller.)

•

If the

F3 push button is held pressed during controller reset, the controller is forced to FIX 0,

Suspend Control State. In FIX 0 the control program stops, inputs continue to be measured,

and totalizers and trends continue to update. Outputs reflect the contents of their associ-

ated datapoints. The logo appears on the display. Use the same proce-

dure provided in the table above (press the

F3 instead of F2).

18.7 SUPPLEMENTAL INFORMATION

Schematics and pin assignment illustrations are provided as follows:

Backplane:

•

Figure 18-2. Hand Held Configurer and Valve Holder Pin Assignments

•

Figure 18-3. Cord Set Connector Pin Assignments

Interconnection Terminal Boards (ITBs):

•

Figure 18-4. Cord Set ITB Schematic

•

Figure 18-5. Dual Relay ITB Schematic

•

Figure 18-6. 6 Digital Input/4 Digital Output (6DI/4DO) ITB Schematic

•

Figure 18-7. 16 Digital Input/Digital Output (16DI/DO) ITB Schematic

•

Figure 18-8. Analog ITB Schematic

•

Figure 18-9. Communication ITB Schematic

Expansion Board Option Cards:

•

Figure 18-10. 6 Digital Input/4 Digital Output (6DI/4DO) PCB Option

•

Figure 18-11. 16 Digital Input/Digital Output (16DI/DO) PCB Option

•

Figure 18-12. Single Channel Analog Input PCB Option

•

Figure 18-13. Multi I/O Analog PCB Option

•

Figure 18-14. High Speed Communications PCB Option

Section 18. Maintenance and Parts List

18-13