A1-a3, Figure 3.2 drive connections for frames a1 – a4 – Rockwell Automation 1336E IMPACT Adjustable Frequency AC Drive User Manual V 1-4.XX User Manual

Page 50

3-2

Mounting and Wiring Information Specific to Frames A1, A2, A3, and A4

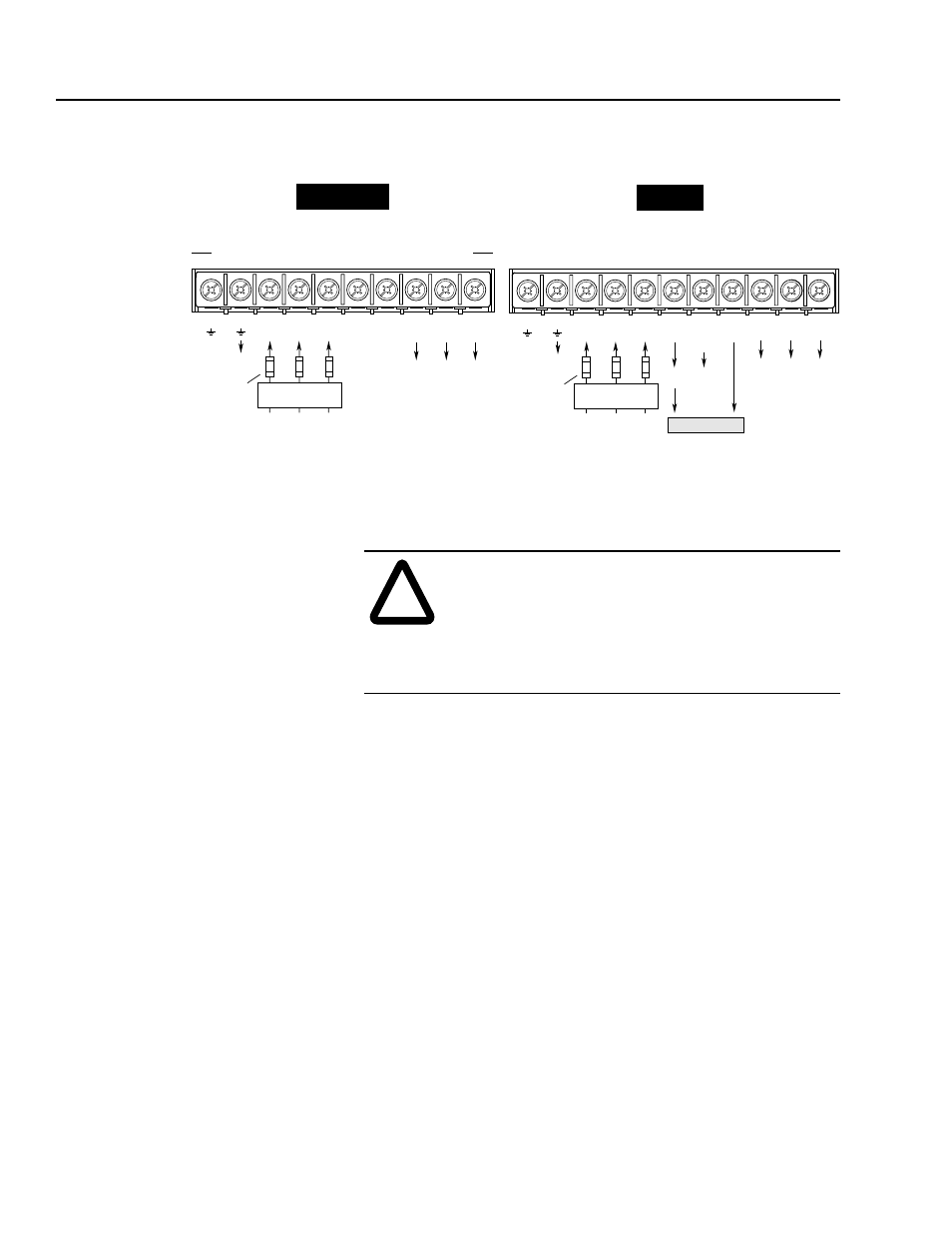

The drive connections for TB1 are shown in Figure 3.2.

Figure 3.2

Drive Connections for Frames A1 – A4

GRD

GRD

To Motor

Required

Input Fusing

R

(L1)

S

(L2)

T

(L3)

DC

+

DC

–

U

(T1)

V

(T2)

W

(T3)

AC Input Line

To Motor

200-240V, 0.37-3.7 kW (0.5-5 HP) Terminal Designations

380-480V, 0.37-3.7 kW (0.5-5 HP) Terminal Designations

Dynamic Brake

Option

A1-A3

Frame

Required Branch

Circuit Disconnect

GRD

GRD

R

(L1)

S

(L2)

T

(L3)

DC

+

BRK

–

DC

–

COM

U

(T1)

V

(T2)

W

(T3)

AC Input Line

To Motor

380-480V, 5.5-7.5 kW (7.5-10 HP) Terminal Designations

500-600V, 0.75-7.5 kW (1-10 HP) Terminal Designations

To Motor

Required

Input Fusing

A4

Frame

Required Branch

Circuit Disconnect

DC Input Line

1

1 User supplied.

2 Before wiring your dynamic brake for the A4 frame, double check the terminals. You should attach the + terminal on

the brake to the DC+ terminal on your drive and the - terminal on the brake to the BRK - terminal on your drive. If your

BRK - terminal is labeled VBUS -, connect the - terminal on the brake to the VBUS - terminal on your drive.

2

!

ATTENTION: If you install control and signal wiring

with an insulation rating of less than 600V, route this

wiring inside the drive enclosure to separate it from any

other wiring and uninsulated live parts. If you do not

separate these wires, you may damage your equipment

or have unsatisfactory drive performance.