Software block diagram – Rockwell Automation 1336E IMPACT Adjustable Frequency AC Drive User Manual V 1-4.XX User Manual

Page 332

A-6

Specifications

–

Classes 7 and 8 may have their respective circuits pulled in

the same conduit or layered in the same tray.

Note: Encoder cables run in a bundle may experience some amount

of EMI coupling. The circuit application may dictate separate

spacing.

–

Classes 9, 10, and 11 may have their respective circuits pulled

in the same conduit or layered in the same tray.

Communication cables run in a bundle may experience some

amount of EMI coupling and corresponding communications

faults. The application may dictate separate spacing.

3. All wires of classes 7 through 11 must be shielded per the

recommendations.

4. In cable trays, steel separators are advisable between the class

groupings.

5. If conduit is used, it must be continuous and composed of

magnetic steel.

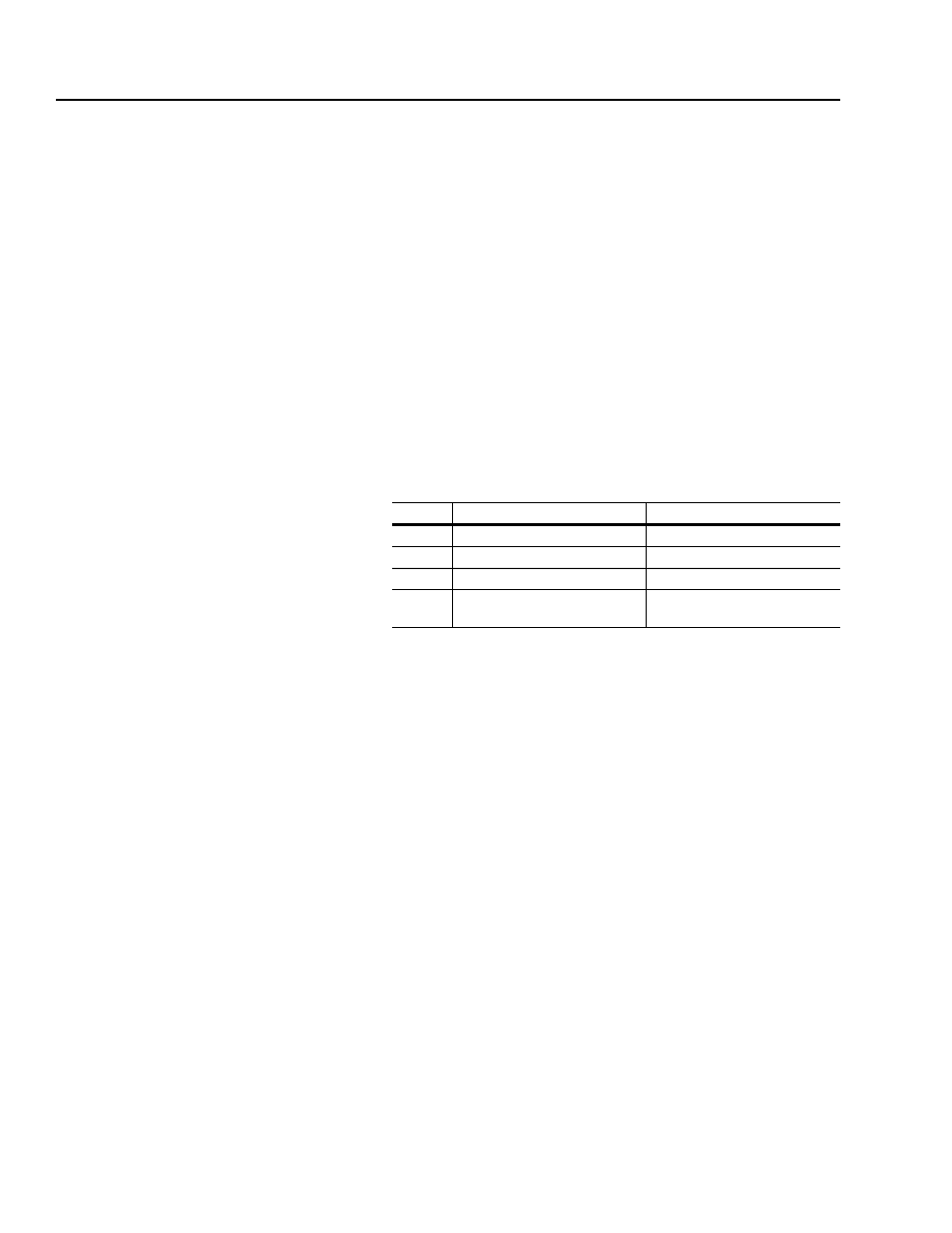

6. Spacing of communication cables classes 2 through 6 is:

General Notes

•

Steel conduit is recommended for all wiring classes

(Classes 7 – 11).

•

Spacing shown between classes is the minimum required for

parallel runs less than 400 feet. Greater spacing should be used

where possible.

•

Shields for shielded cables must be connected at one end only.

The other end should be cut back and insulated. Shields for cables

from a cabinet to an external device must be connected at cabinet

end. Shields for cables from one cabinet to another must be

connected at the source end cabinet. Splicing of shielded cables,

if absolutely necessary, should be done so that shields remain

continuous and insulated from ground.

•

Power wire is selected by load. 16 AWG is the minimum

recommended size for control wiring.

Software Block Diagram

The following figures show the parameter linking and interactions

within the 1336 IMPACT drive. For more information about

parameter linking, refer to Chapter 6, Starting Up Your System.

Volts

Conduit Spacing

Through Air

115

1 inch

2 inches

230

1.5 inches

4 inches

460/575

3 inches

8 inches

575

proportional to 6 inches per 1000

volts

proportional to 12 inches per

1000 volts