Getting started – Lenze ETC Motion Control User Manual

Page 37

Getting started

Parameterising drives via machine constants

Overview of the most important machine constants

2.8

2.8.1

l

37

EDSTCXN EN 2.0

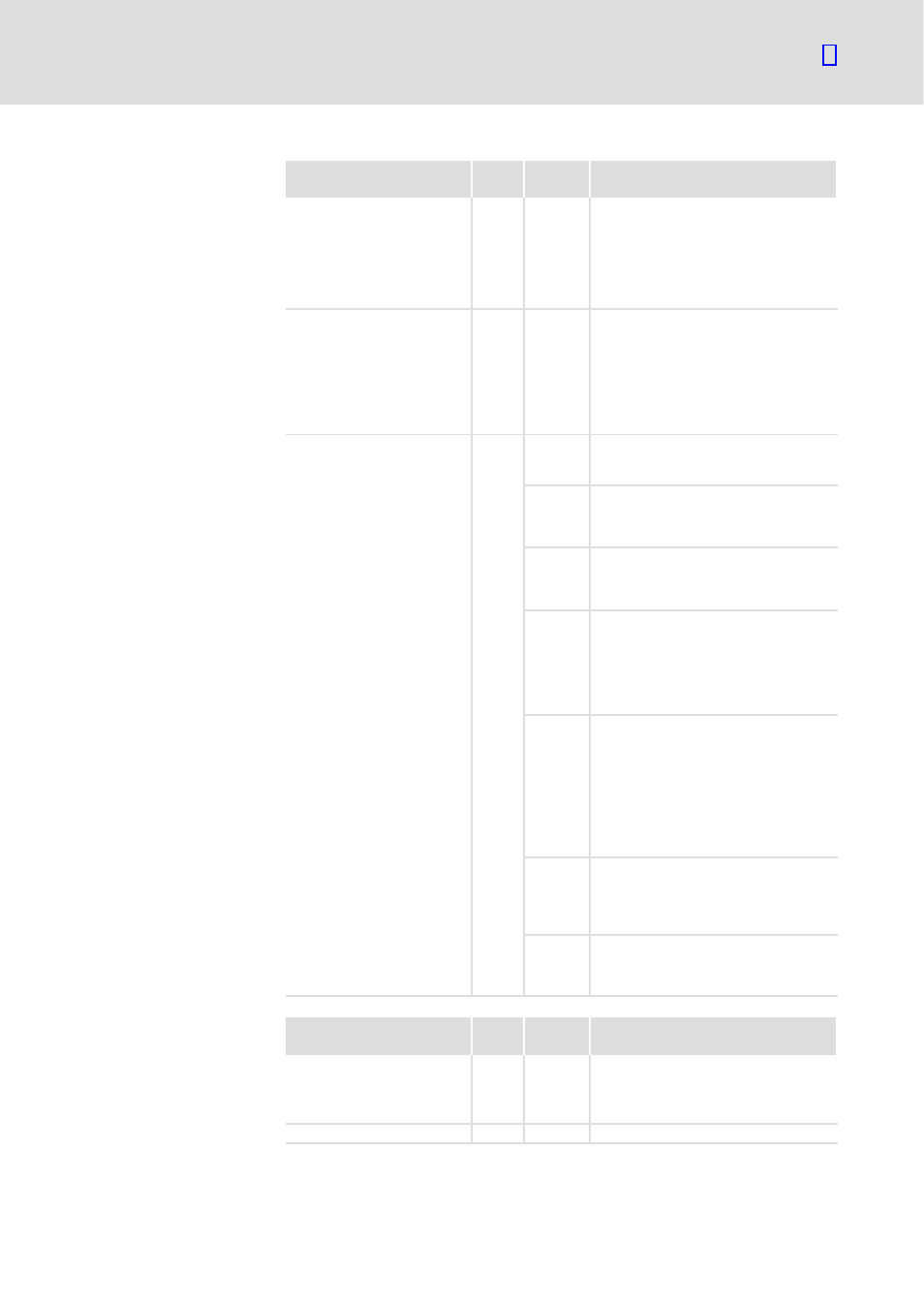

MC keyword

No. of

values

Values

Meaning

MK_CANDRIVES

12

−1, 0 ... 11 Assignment of the axis number 0 ... 11 to

the CAN node address in the order of the

CAN node address 1 ... 12

−1: No axis number is assigned to the

node address

0 ... 11: An axis number is assigned to the

node address

MK_APPLACHSIDX

18

−1, 0 ... 11 Assignment of the axis number 0 ... 11 to

the axis description in the order of the

axis description X ,Y, Z, C, U, V, W, A, B, u,

v, w, x, y, z, a, b, c

−1: No axis number is assigned to the axis

description

0 ... 11: An axis number is assigned to the

axis description

MK_ACHSENART

12

Assignment of the axis type to the axis

number in the order of the axis number 0

... 11

Bit 0 Axis type

xxxxxxx0

Linear axis

xxxxxxx1

Rotation axis

Bit 1 Limit switch

xxxxxx0x

Observe HW limit switch

xxxxxx1x

Ignore HW limit switch

Bit 3/2

Axis type

xxxx00xx

Normal axis

xxxx01xx

Spindle

xxxx10xx

Measurement axis

xxxx11xx

Spindle and measurement axis

Bit 5/4

Only for xxxxxxx1,

rotation axis

xx00xxxx

Rotation axis with absolute

positioning

xx01xxxx

Modulo 360° axis − sign indicates the

direction

xx11xxxx

Modulo 360° axis − shortest distance

is travelled (ETCHC only)

Bit 6 Gantry axis

x0xxxxxx

Normal axis

x1xxxxxx

Gantry axis (synchronous axis with

mechanical coupling)

Bit 7 Handwheel

0xxxxxxx

Normal axis

1xxxxxxx

Handwheel

MC keyword

No. of

values

Values

Meaning

MK_CANOPEN_BAUDRATE

2

0,

10... 1000

1st parameter for CAN1

2nd parameter for CAN1

0: no device connected

>0: baud rate for CAN−Open in kB

MK_DELTAT

1

Rough interpolation cycle in [ms]

Hardware configuration

Software configuration