Cnc programming, Data fields p field – Lenze ETC Motion Control User Manual

Page 186

CNC programming

Data fields

P field

3.5

3.5.1

l

186

EDSTCXN EN 2.0

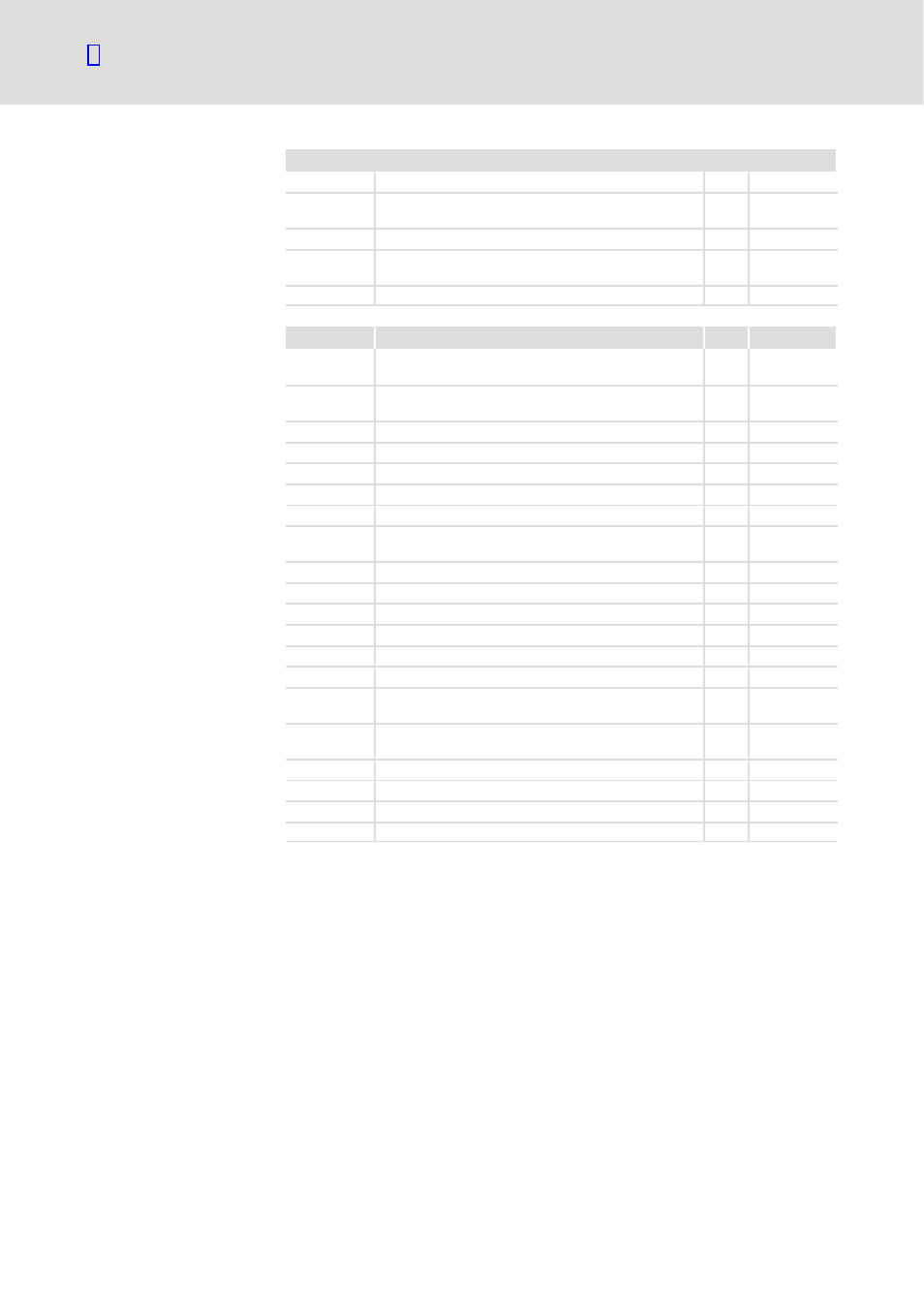

Unit

Sync

Meaning

Index

674

Conversion factor of input units in mm

mm/Einh

675

Conversion factor of m/min by input units/GIT

x

Unit/GIT

m/min

676

Conversion factor of input units/min in input units/GIT

x

min/GIT

677

Conversion factor of m/s

2

in input units/GIT

2

x

Unit/GIT

2

m/s

2

678

Conversion factor of input units/s

2

in input units/GIT

2

x

s

2

/GIT

2

Index

Meaning

Sync

Unit

288 ... 303

Analogue measured value of channel 0 ... 15 (−>

MK_MESS_AUFLOESUNG)

x

MC

368 ... 373

Axis positions, determined by measuring cycles, for a

basic rotation

x

mm *

374 ... 376

Basic rotation angle A, B, C in the YZ, ZX and XY plane

x

°

685

Thread pitch (G33)

x

mm *

686

Thread pitch correction (G33)

x

mm *

687

Thread cylinder correction (G33)

x

mm *

688

Thread measurement distance (G33)

x

mm *

690

Radius in the polar machine coordinate system

(MK_MASCH_POL...)

x

mm *

691

Angle in the polar machine coordinate system

x

°

692

Angle of the C−axis in the polar coordinate system

x

°

696

Angle of the oblique X−axis from MK_X_WINKEL

x

°

697

Sinus of the angle of the oblique X−axis

x

−−−

698

Cosinus of the angle of the oblique X−axis

x

−−−

699

Tangent of the angle of the oblique X−axis

x

−−−

700 ... 725

Tool data (Tn) of channel 0,

P700 = tool radius [mm]

x

−−−

730 ... 755

Tool data of channel N (−> P576)

P730 = tool radius [mm]

x

−−−

760 .. 769

Technology data from MK_TECHNOLOGIEDATEN1

−−−

770 ... 779

Technology data from MK_TECHNOLOGIEDATEN2

−−−

780 ... 789

Technology data from MK_TECHNOLOGIEDATEN3

−−−

790 ... 799

Technology data from MK_TECHNOLOGIEDATEN4

−−−

Technology−specific

parameter