Cnc programming – Lenze ETC Motion Control User Manual

Page 188

CNC programming

Data fields

P field

3.5

3.5.1

l

188

EDSTCXN EN 2.0

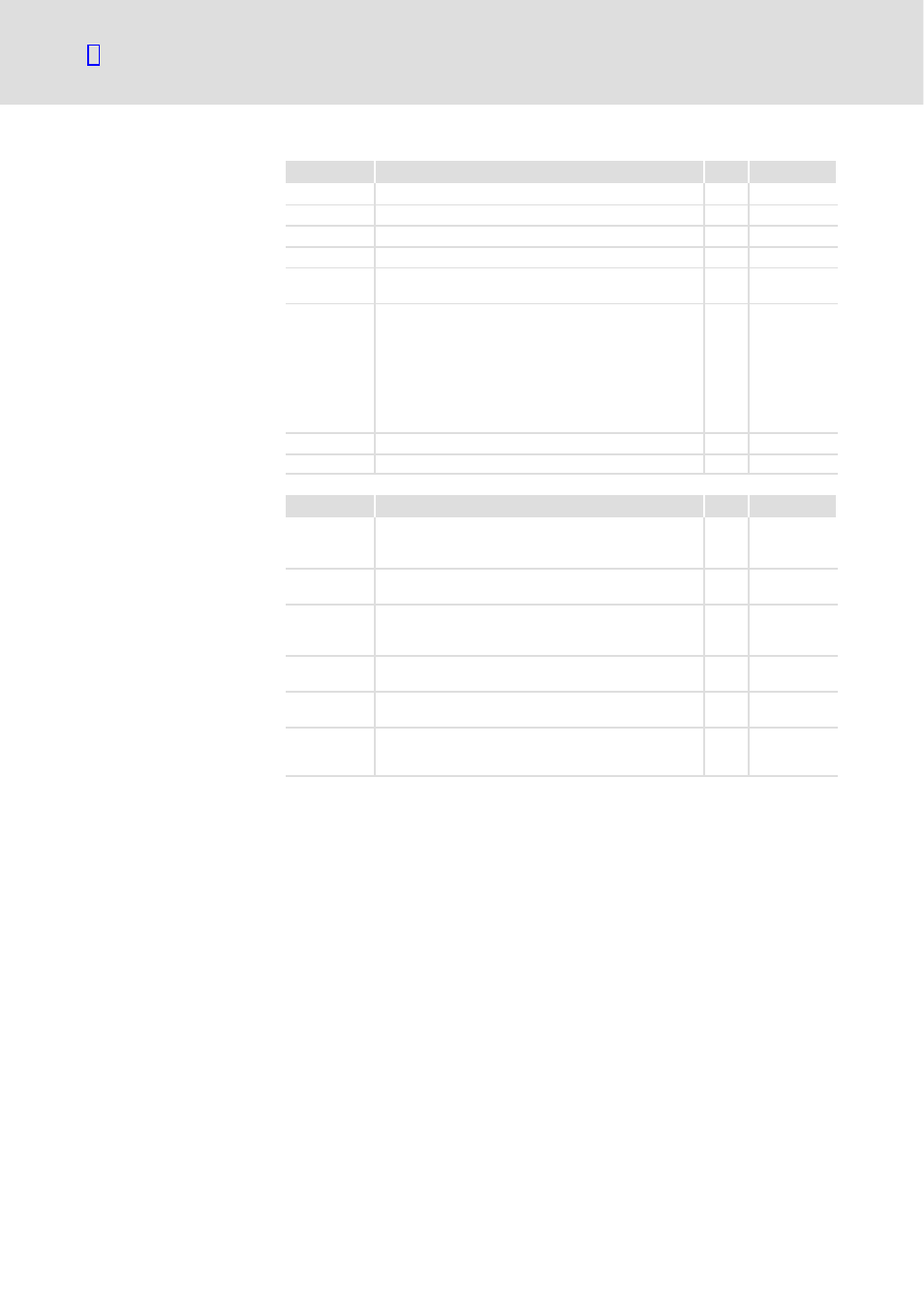

Index

Meaning

Sync

Unit

1040

Intended speed for axis positioning

mm/min *

1041

Target speed on reaching the target point

mm/min *

1042

Intended traverse path after triggering

mm *

1043

Accumulated actual traverse path after triggering

mm *

1044

Number of the input, which should be used as a trigger

signal (0 ... 23)

−−−

1045

Positioning state

0: Standstill,

1: Find trigger signal,

2: Positioning running,

3: Intended traverse path reached or exceeded (P1041

!= 0),

4: Intended traverse path reached, standstill (P1041 ==

0)

−−−

1046

Acceleration and brake ramp

m/s

2

*

1047

Current default speed on the positioning axis

mm/min *

Index

Meaning

Sync

Unit

1050

Y−correction value which is added for each mm of feed

of the X−axis to the position of the Y−axis. Only in the

case of spindle type 6

−−−

1051

Number of stitches of sewing head 1 since the control

was switched on

−−−

1052

Number of stitches of sewing head 2 since the control

was switched on, only in the case of spindle type 5 and

two sewing heads

−−−

1057

Speed specification from PLC to spindle handler for

speed reduction during sewing.

1/min

1058

Path target specification for customer−specific

comparative operation of type 2

mm *

1059

Corner speed of the sewing motor in percent of the

setpoint speed, for reducing the speed for

non−tangential block transitions

%

Axis positioning handler for

handling tasks (G97 X10)

Sewing (G97 X5|X6)