Cnc programming – Lenze ETC Motion Control User Manual

Page 182

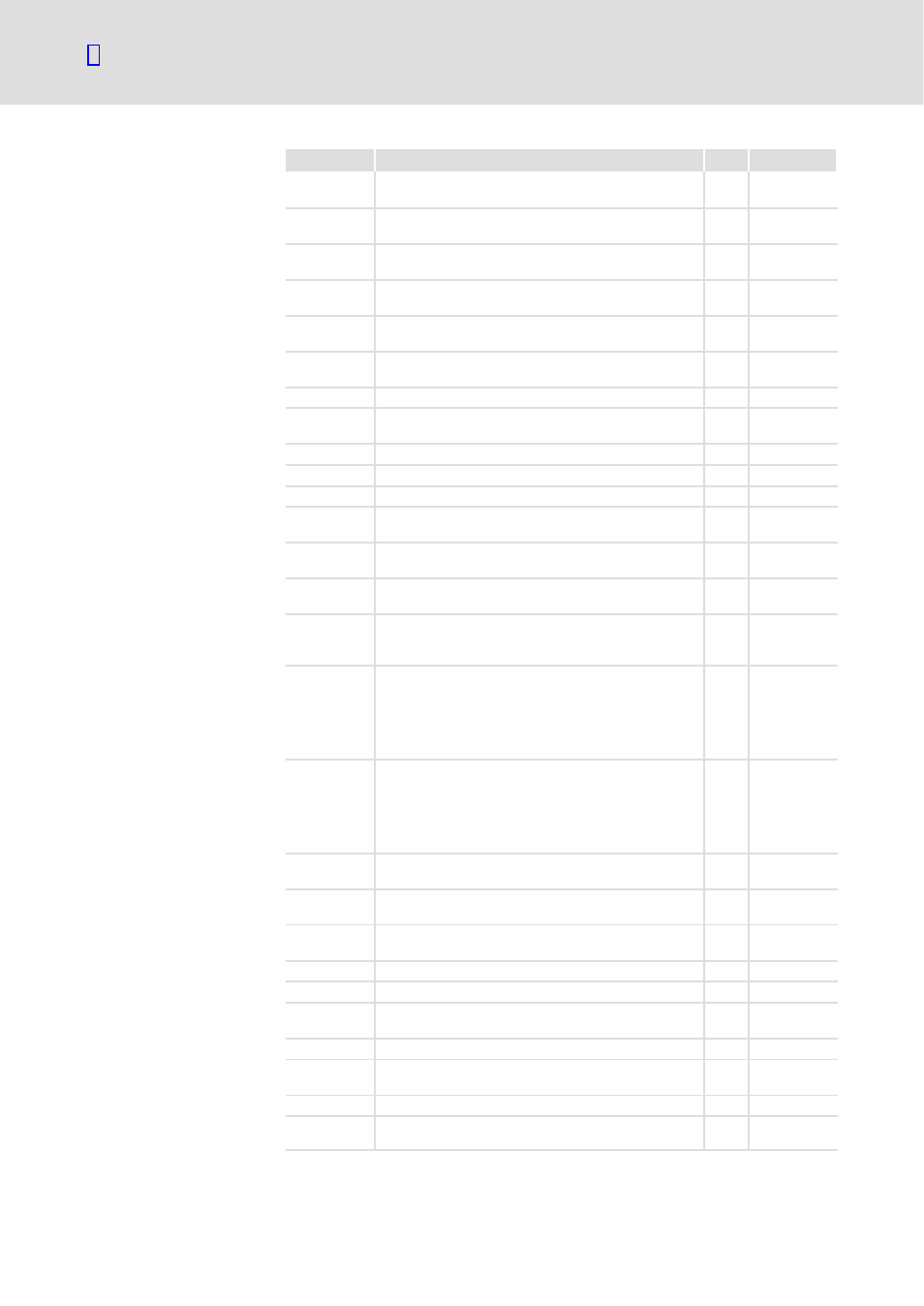

CNC programming

Data fields

P field

3.5

3.5.1

l

182

EDSTCXN EN 2.0

Unit

Sync

Meaning

Index

112 ... 127

Zero point offset of coordinate system Tn (−> P585) from

channel N

x

mm *

128 ... 143

Zero point offset of coordinate system Tn (−> P553) from

channel 0

x

mm *

144 ... 159

Modal target position of the axes in reference to the

current coordinate system

x

mm *

160 ... 175

Modal actual position of the axes in reference to the

current coordinate system

x

mm *

176 ... 191

Modal target position specification in reference to the

current coordinate system

x

mm *

192 ... 207

NC total offset of the axes of S0+Sn+Tn

(channel−independent)

x

mm *

208 ... 223

Modal speed specification of the axes

x

mm/min *

224 ... 239

Real actual position of the axes related to the basic

offset

x

Inc

240 ... 255

Modal acceleration specification of the axes

x

m/s

2

*

256 ... 271

Tolerance margin of the axes

x

Inc

272 ... 287

Modal actual speed of the axes

x

mm/min *

304 ... 319

Negative software traverse limits of the axes related to

the basic offset

x

mm *

320 ... 335

Real actual position of the axes related to the basic

offset

x

mm *

336 ... 351

Positive software traverse limits of the axes related to

the basic offset

x

mm *

352 ... 367

Saved actual positions of the axes related to the basic

offset, these are saved by an external trigger signal at

the same time

x

mm *

394 ... 409

States of the input signals of the axes (limit switch,

reference cam,...)

Bit0: positive limit switch

Bit1: negative limit switch

Bit2: reference cam

Bit3: reserve input

x

−−−

410 ... 425

States of the input signals of the slave axes for

synchronous axes.

Bit0: positive limit switch

Bit1: negative limit switch

Bit2: reference cam

Bit3: reserve input

x

−−−

426 ... 441

Synchronous distance between master and slave axes

for synchronous axes

x

mm *

442 ... 457

Min. synchronous distance, determined via 200 fine

interpolation cycles

x

mm *

458 ... 473

Max. synchronous distance, determined via 200 fine

interpolation cycles

x

mm *

480 ... 495

Conversion factor of input units in increments

x

Inc/mm *

496 ... 511

Basic offset from the MCs (MK_GRUNDOFFSET)

x

mm *

640 ... 655

Default speed of the axes for use in cycles, initialized to

the value of the maximum speed in MK_VMAX

x

mm/min *

928 ... 943

Additional basic offset of the axes (G194)

x

mm *

944 ... 959

Desired positions of the axes including all the

transformations and coordinate system offsets

x

mm *

960 ... 975

Extension factors of the axes (G75)

−−−

992 ... 1007

Programmed target position from the last interpreted

DIN block

mm *