Cnc programming – Lenze ETC Motion Control User Manual

Page 116

CNC programming

G functions

G functions individual descriptions

3.2

3.2.2

l

116

EDSTCXN EN 2.0

3.2.2.22

G41 Tool path correction − left, G42 Tool path correction − right

Switching on the tool radius compensation or an application−specific

correction procedure for the tool path.

G41 R J L

G42 R J L

R

Tool radius to be compensated

J

Tool orientation (value 0 ... 9)

L

Transfer type 0: linear, 1: circular

The preparatory functions switch on the tool radius compensation or an

application−specific correction procedure. The tool radius is transferred from

the parameter field (P700), which is preset with a T change−over or can

possibly be programmed directly with the code letter R. In the case of

application−specific corrections, the dimensions are transferred via agreed

interfaces (parameter field, machine constants). G41 activates a correction

to the left, G42 to the right of the programmed path, related to the direction

of the tool movement. The compensation applies to the selected plane (G17,

G18, G19). After the compensation has been selected, the compensated

path is approached with the following block. The starting point of this block

is the current actual position, the target point lies on the compensated path

(intersection point with following block).

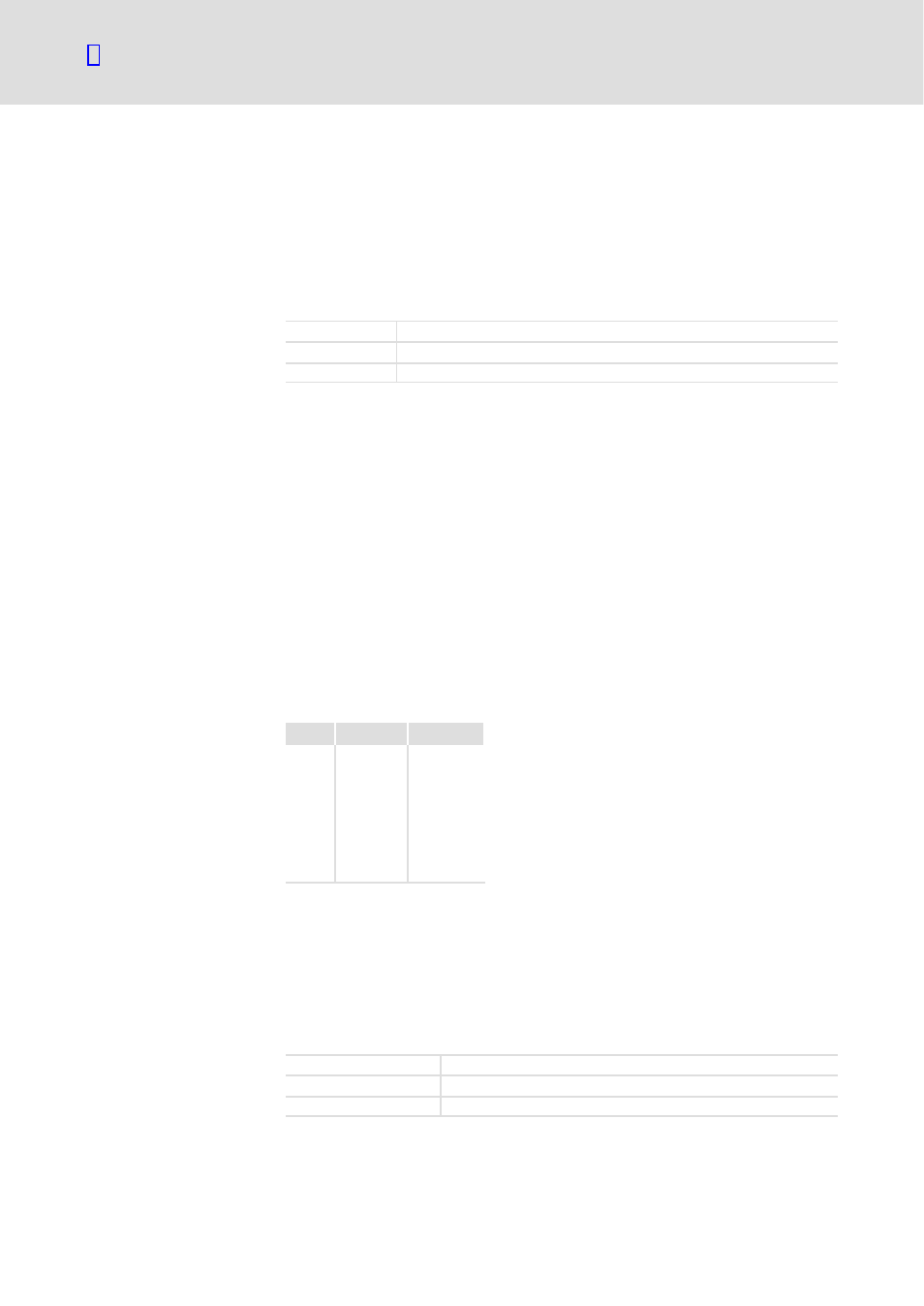

Refer to the following table for the corresponding tool orientation J. It shows

the relation between the coordinates of the cutting center (Xs,Ys) and the

coordinates of the tool cutting point (Xp,Yp) for every orientation value.

J

Xp

Yp

0

1

2

3

4

5

6

7

8

Xs

Xs+R

Xs−R

Xs−R

Xs+R

Xs+R

Xs

Xs−R

Xs

Ys

Ys+R

Ys+R

Ys−R

Ys−R

Ys

Ys+R

Ys

Ys−R

The tool path correction works according to the intersection point

procedure. If the profile transition angle is wide, the intersection point can

be located very far from the path. In this case, linear intermediate blocks (L0,

profile transition angle > 270 degrees) or a circular transition (L1, profile

transfer angle > 180 degrees) are generated. The compensation is switched

off by G40. Changing from G41 <−> G42 without intermediate G40 is

allowed.

N100 G41 R1

Tool radius correction with 1 mm tool radius "on".

N110 G1 X10

Approach block

N120 G1 X20 Y10

First profile block

Syntax

Meaning of the addresses

Explanation

Example