Cnc programming – Lenze ETC Motion Control User Manual

Page 166

CNC programming

G functions

G functions individual descriptions

3.2

3.2.2

l

166

EDSTCXN EN 2.0

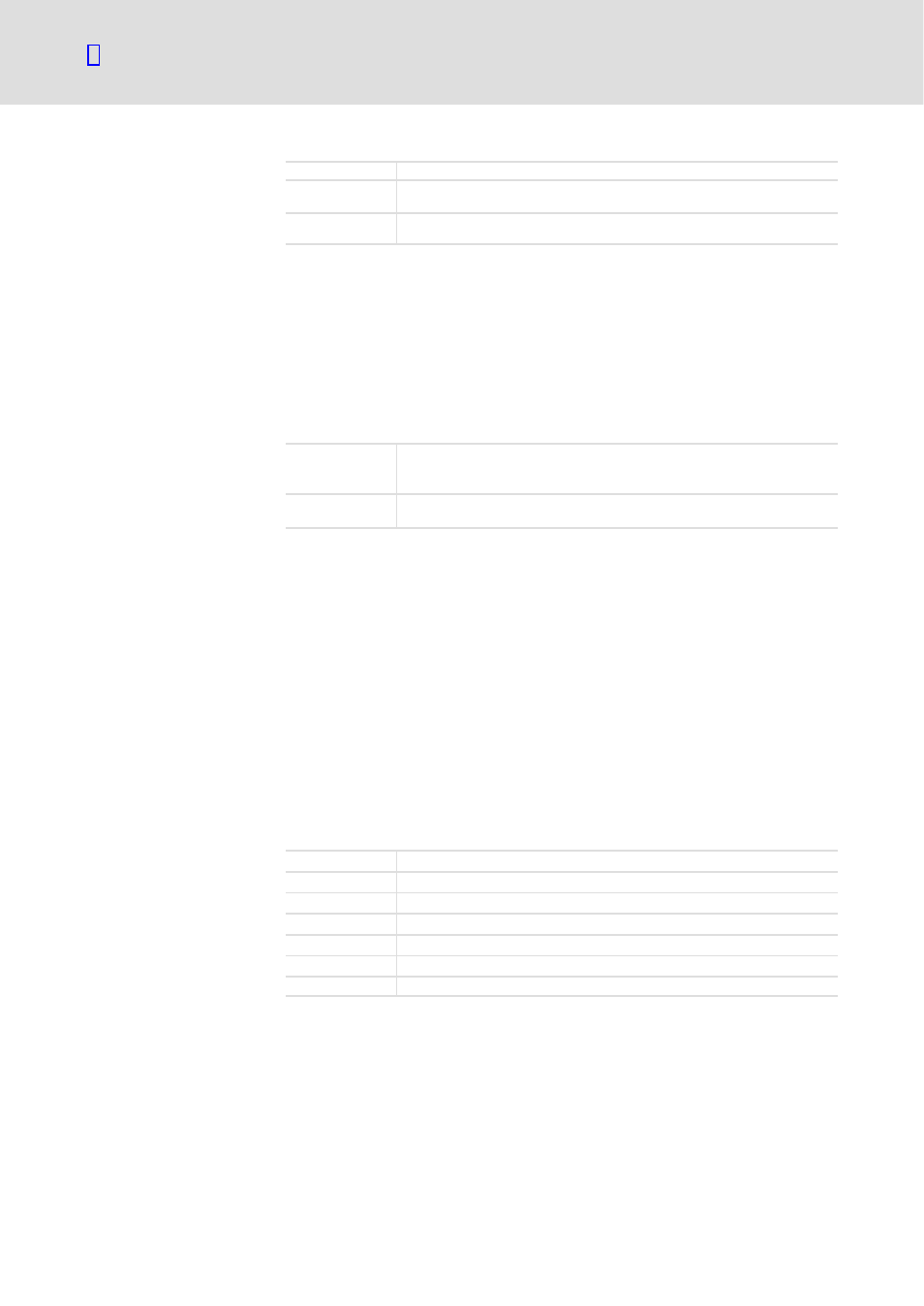

BYTE

unsigned 8−bit integer

ULONG

unsigned 32−bit integer, 4 bytes long, with the byte with the lowest value

first

FLOAT

IEEE single precision floating point, 4 byte long, with the byte with the

lowest value of the mantissa first.

3.2.2.78

G234 Direction−dependent height correction

In the case of direction−dependent height correction, the position of the

specified axis is corrected dependent on the driving direction in the current

plane via a grid point table.

G234 AXE K

AXE

Identification of the axis, which should be corrected.

0: correction "off"

1: correction "on"

K

Parameter field index, from which the correction table is stored in the

P−field.

This function can be used, for example, to correct a Z axis by an offset

dependent on the current driving direction in the XY plane. The correction is

limited to a maximum value of +/−1 input units (e.g. mm or degrees).

With K, the parameter field index is programmed, from which the correction

table is stored in the P field. The first value of the table must contain the

number of the following table values. Every table entry contains a correction

offset for a defined profile angle in the current (time of G234) selected plane.

The table values must cover an angle range of 360

°

, the first table value

applies to a profile angle of 0

°

. The table can have a maximum of 36

entries(10

°

per correction value). The interpolation between the entries is

linear.

The correction is switched off at the end of the program or in the event of a

program termination and by programming G234 without axis letters.

P1200=4

Number of grid points

P1201=0.0

Offset for 0

°

P1202=0.1

Offset for 90

°

P1203=0.2

Offset for 180

°

P1204=0.3

Offset for 270

°

G234 Z1 K1200

Correction of the Z−axis "on"

G234

Correction "off"

Definition of the used data

types

Syntax

Meaning of the addresses

Explanation

Example