Cnc programming – Lenze ETC Motion Control User Manual

Page 181

CNC programming

Data fields

P field

3.5

3.5.1

l

181

EDSTCXN EN 2.0

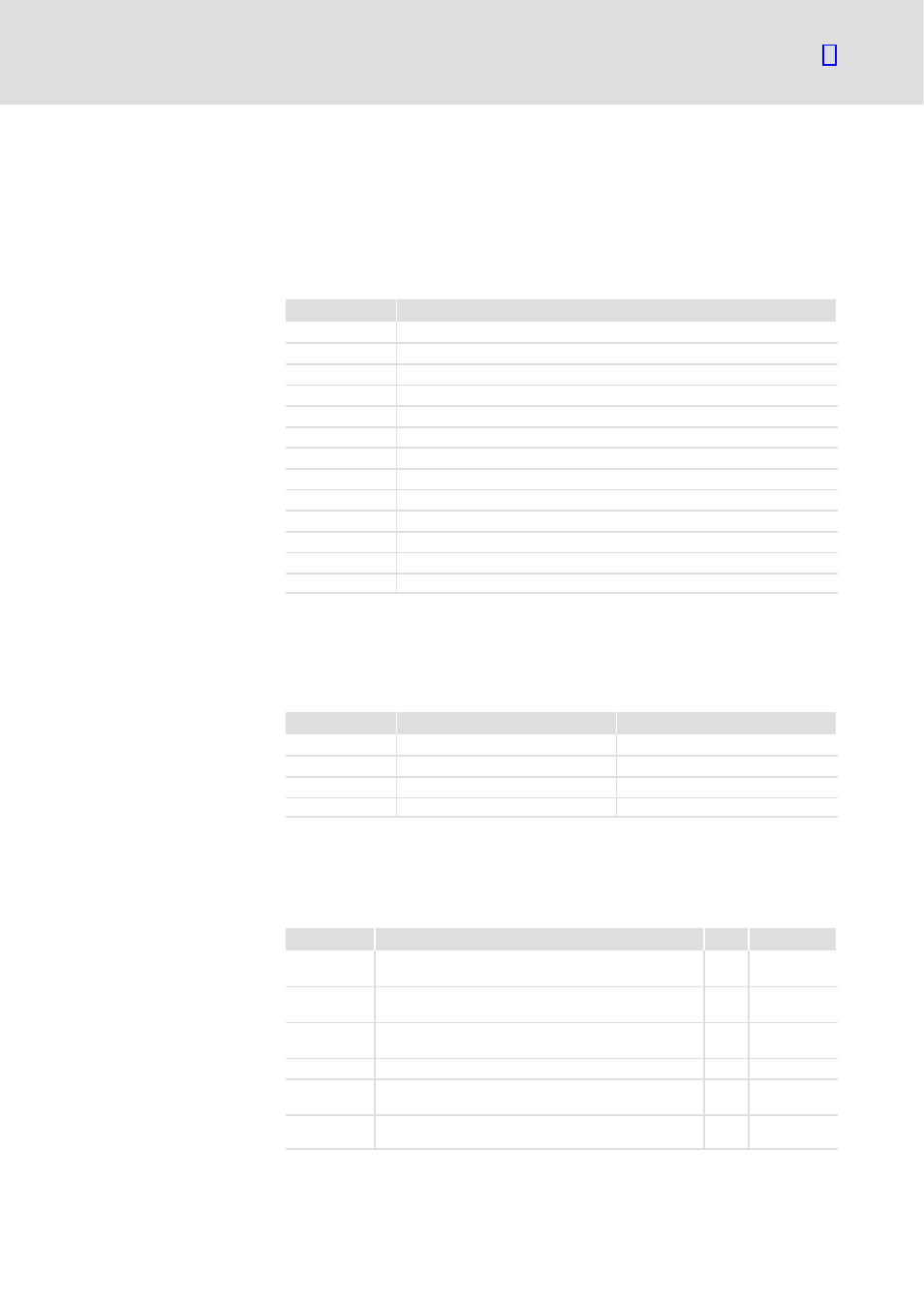

The assignment of the area of the parameter field, in which the internal data

of the NC computer is stored, is specified in the following. The specified digits

correspond to the parameter numbers under which the variables are

addressed. Axis−related values are always entered in the sequence in which

they are defined in the machine constant MK_APPLACHSIDX.

Meaning of the units in the following tables:

Unit

Meaning

Inc

Increments

°

Degree

Unit

Translative path input unit, machine constant−dependent (default = mm)

mm

Millimeter

m

Meter

h

Hour

min

Minute

s

Second

ms

Millisecond

GIT

Coarse interpolation cycle

MC

Unit is dependent on the machine constants

%

The parameter is specified in percent

−−−

The parameter has no unit

With some parameters, the unit is dependent on whether the parameter

belongs to a linear axis or a rotation axis. In the case of linear axes, the input

unit is also dependent on the value in the machine constants

MK_METRISCH, MK_CONST_REL_MM and MK_CONST_REL_INCH. The

following enhanced table applies to these parameters.

Unit

Meaning with linear axes

Meaning with rotation axes

mm *

Input unit

Degree

mm/min *

Input units/minute

Revolutions/minute

m/s

2

*

Meter/second

2

Revolutions/second

2

Inc/mm *

Increments/input unit

Increments/degree

A cross in field "Sync" indicates that the access to the corresponding

parameter is time synchronized, i.e. that the contents of the parameter in a

NC program is only read when the block was executed before. The further

interpretation of the NC program is also stopped until this has happened.

Index

Meaning

Sync

Unit

0 ... 15

NC actual position of the axes in reference to the

current coordinate system

x

mm *

16 ... 31

Total of modal actual position and NC actual position of

the axes (P160ff+P0ff)

x

mm *

32 ... 47

NC target position of the axes in reference to the

current coordinate system

x

mm *

64 ... 79

Zero point offset of coordinate system S0

x

mm *

80 ... 95

Zero point offset of coordinate system Sn (−> P586) from

channel N

x

mm *

96 ... 111

Zero point offset of coordinate system Sn (−> P554) from

channel 0

x

mm *

Assignment of system

parameters

Axis−specific parameters