2 q field, Q field, Cnc programming – Lenze ETC Motion Control User Manual

Page 189

CNC programming

Data fields

Q field

3.5

3.5.2

l

189

EDSTCXN EN 2.0

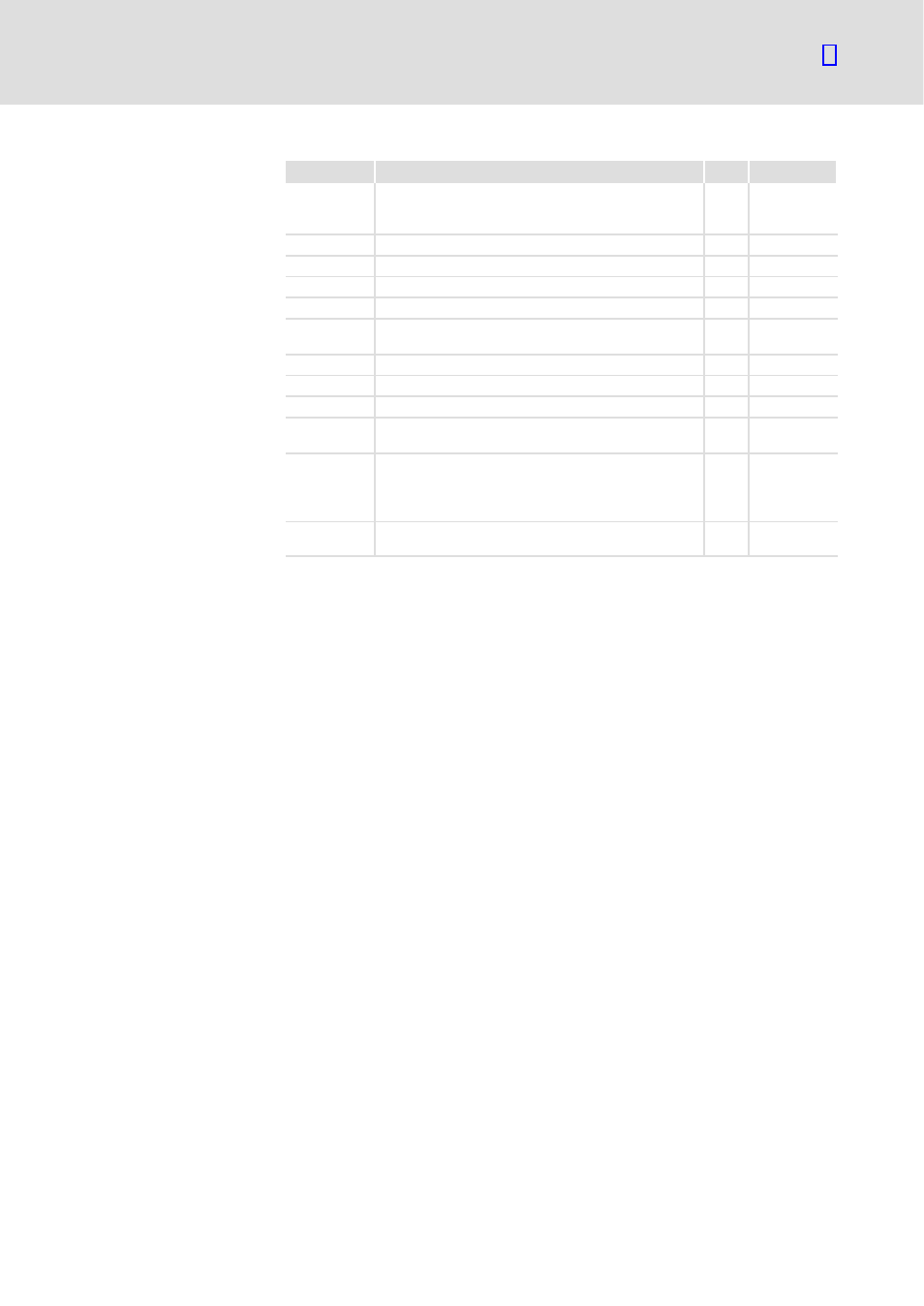

Index

Meaning

Sync

Unit

1060

This is set when a probing has happened. It can be used

in the probe cycle as a condition for a modal branch

(G130)

−−−

1061

Number of error triggered for diagnosis purposes

−−−

1062

Probe path, reserved for probe cycle

mm *

1063

Probe path tolerance, reserved for probe cycle

mm *

1064

Probe speed, reserved for probe cycle

mm/min *

1065

Deceleration ramp to stop the traverse movement after

a probe

m/s

2

*

1066

Rectraction speed after probing

mm/min *

1067

Rectraction acceleration after probing

m/s

2

*

1068

Rectraction path relative to the probing position

mm *

1069

Waiting time after probing triggering for filtering out

triggered errors

ms

1070

Probe status

0: no probing taken place yet

1: valid probing taking place

2: probing could be valid, decision in the next GIT

1071 ... 1086 Saved probing positions. For the pos. edge these are

accepted at the trigger signal.

mm *

3.5.2

Q field

The Q field is a bit−oriented field with a size of 64 bits. The Q field can be used

to control the progress of a NC program (e.g. G150) by means of external

events. The individual bits can be controlled by the PLC in data block 1. The

assignment can be freely defined by the user.

If fast inputs are configured (see MC and NC software manual), the

corresponding Q bits are not read from data block 1 of the PLC, but rather

directly from the corresponding inputs.

Rectraction handler for

measurement machine