Cnc programming – Lenze ETC Motion Control User Manual

Page 143

CNC programming

G functions

G functions individual descriptions

3.2

3.2.2

l

143

EDSTCXN EN 2.0

N10 G31

Path operation

N20 G01 X50 C0 F5000

Approach starting position

N30 G60 X0

Switch Look Ahead "on"

N40 G142 D500 X20 L0 E0

Noncircular grinding for smooth profile "on"

N41 G5 X24.142 Y−14.142 I3 L1

Switch spline interpolation for closed curve "on"

N42 G143 X15 D7.5 F5000 L3 I0

Rough−grinding two revolutions

N43 G143 X5 D5 F5000 L3 I1

Finish grinding with a spark−out revolution

N44 G143 X−20 D20 F5000 L3

Withdraw

N45 G5

Switch spline interpolation off

N46 G140

Noncircular grinding "off"

N50 G60

Switch Look Ahead "off"

N60 M30

Program end

%3

N10 X24.142 Y14.142

Subprogram for describing the finished profile

N20 X10 Y20

N30 X−4.142 Y14.142

N40 X−10 Y0

N50 X−4.142 Y−14.142

N60 X10 Y−20

N70 X24.142 Y−14.142

N80 X30 Y0

N90 G99

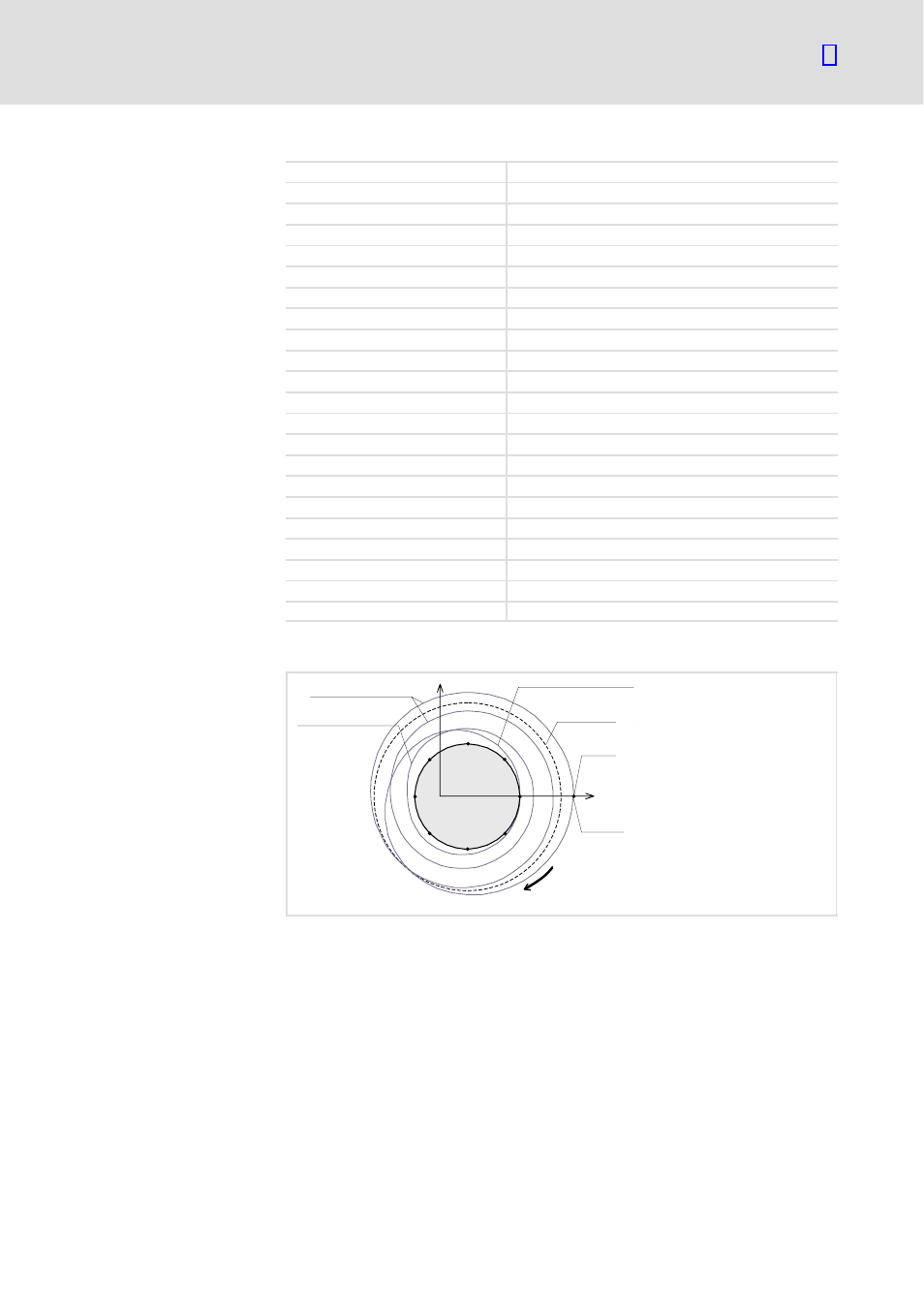

Position of X−axis in the Cartesian coordinate system:

C0

C90

Drehrichtung

des Werkstücks

G143 X15 D7.5 L3 F5000

G143 X5 D5 L3 F5000 I1

Anfangsaufmass

Startpunkt

2

0

1

ETCN052

0 Start overmeasure

1 Starting point

2 Direction of rotation of the workpiece

The workpiece is only approached during the first revolution because the

actual overmeasure is smaller than the defined overmeasure.

The withdrawal from the finished profile also takes place via G143, by

programming the overmeasure and the positioning amount negatively.

Example