Interface plc <˘> nc operating system – Lenze ETC Motion Control User Manual

Page 257

Interface PLC <˘> NC operating system

Definitions

Data block 1

5.1

5.1.2

l

257

EDSTCXN EN 2.0

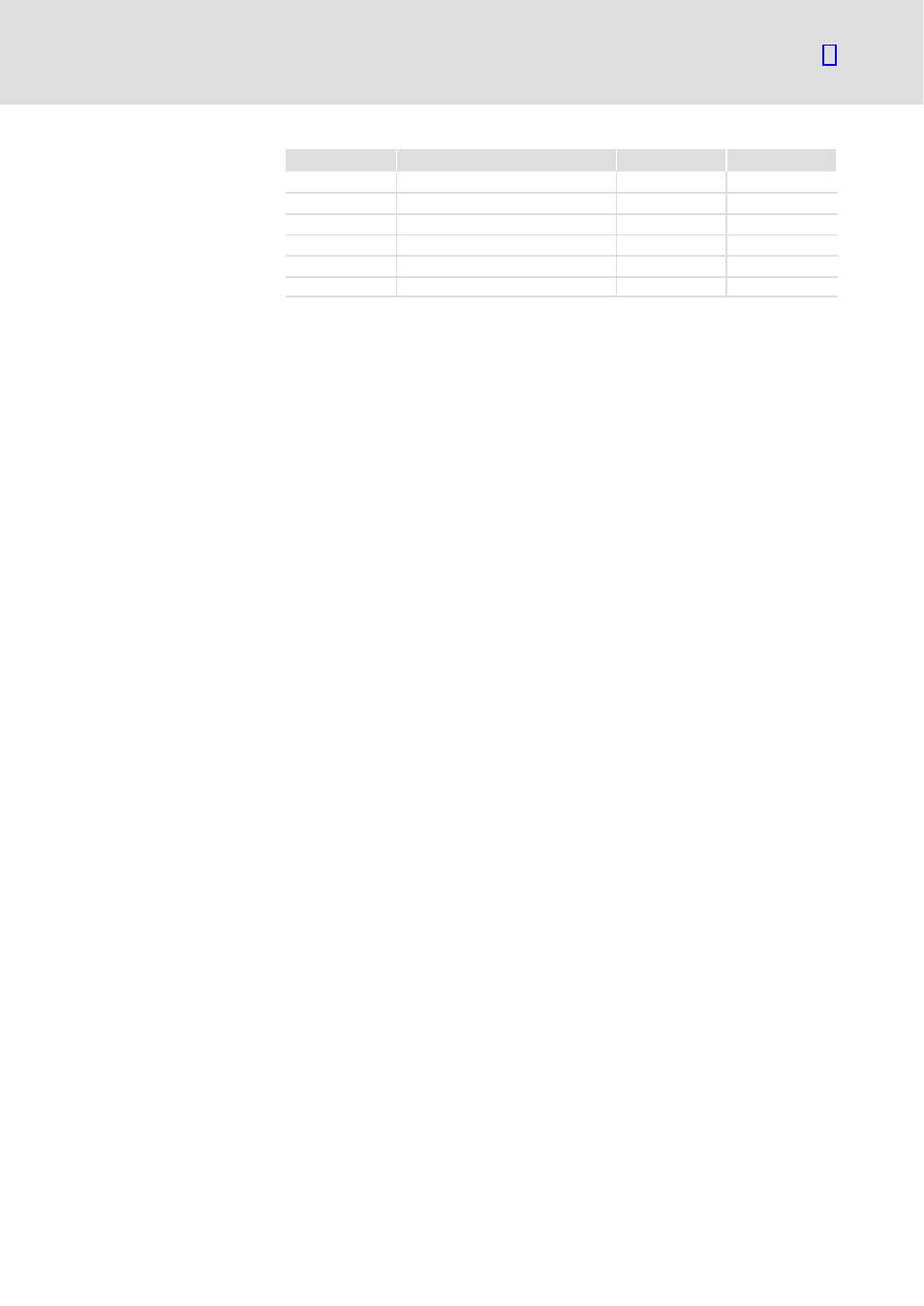

Data word

Name

Direction

Type of signal

084.00−07

Traverse key axis 0

PLC

→

NC

static

084.08−15

Traverse key axis 1

PLC

→

NC

static

...

...

...

...

...

...

...

....

091.00−07

Traverse key axis 14

PLC

→

NC

static

091.08−15

Traverse key axis 15

PLC

→

NC

static

These signals are used for traversing the axes. One byte is available for each

axis. By writing the bytes, the respective action is executed. These traverse

keys are only active if traverse keys enable is not set.

Effect in the NC:

−100 ... +100: traversing with % of the maximum speed. The sign defines the

direction.

+/−101: inching by increments (corresponding to DB15 DW44 ... 47) on the

path if there is no feed enable. Only available for a programmed traversing

movement.

+/−102: home position approach (sign is ignored)

+/−103: setting zero point (sign is ignored)

+/−104: step travel (P673 increment)

+/−105: handwheel active − evaluation factor 1

+/−106: handwheel active − evaluation factor 3

+/−107: handwheel active − evaluation factor 10

+/−108: handwheel active − evaluation factor 30

+/−109: handwheel active − evaluation factor 100

+/−110: traverse command for PLC axis

+/−111: traversing with the speed from P208−223.

The sign specifies the direction.

Description of the traverse command for PLC axes: The PLC can move any

axis to a specific position that has been entered in the P field. The following

parameters are used for this purpose:

P176 ... 191 = target position specification by PLC for axes 0 ... 15 [mm] or [

°

]

P208 ... 223 = speed specification by PLC for axes 0 ... 15 [mm/min] or [rpm]

P240 ... 255 = speed specification by PLC for axes 0 ... 15 [m/sec

2]

or [rps

2

]

The following parameters are available for display:

P144 ... 159 = accepted target position after positive edge of the traverse key

[mm] or [

°

]

P160 ... 175 = current modal actual position [mm] or [

°

]

A target point approach of an axis starts when the value +/−110 is specified

in its traverse key. Make sure in the process that the NC computer detects the

change of the traverse key (if required, observe handshake; see diagram).