Siemens Sinumerik 810T User Manual

Page 47

09.91

2 Operation

2.1.2 SINUMERIK 810T operator interface with external machine control panel

•

the spindle is brought to a standstill.

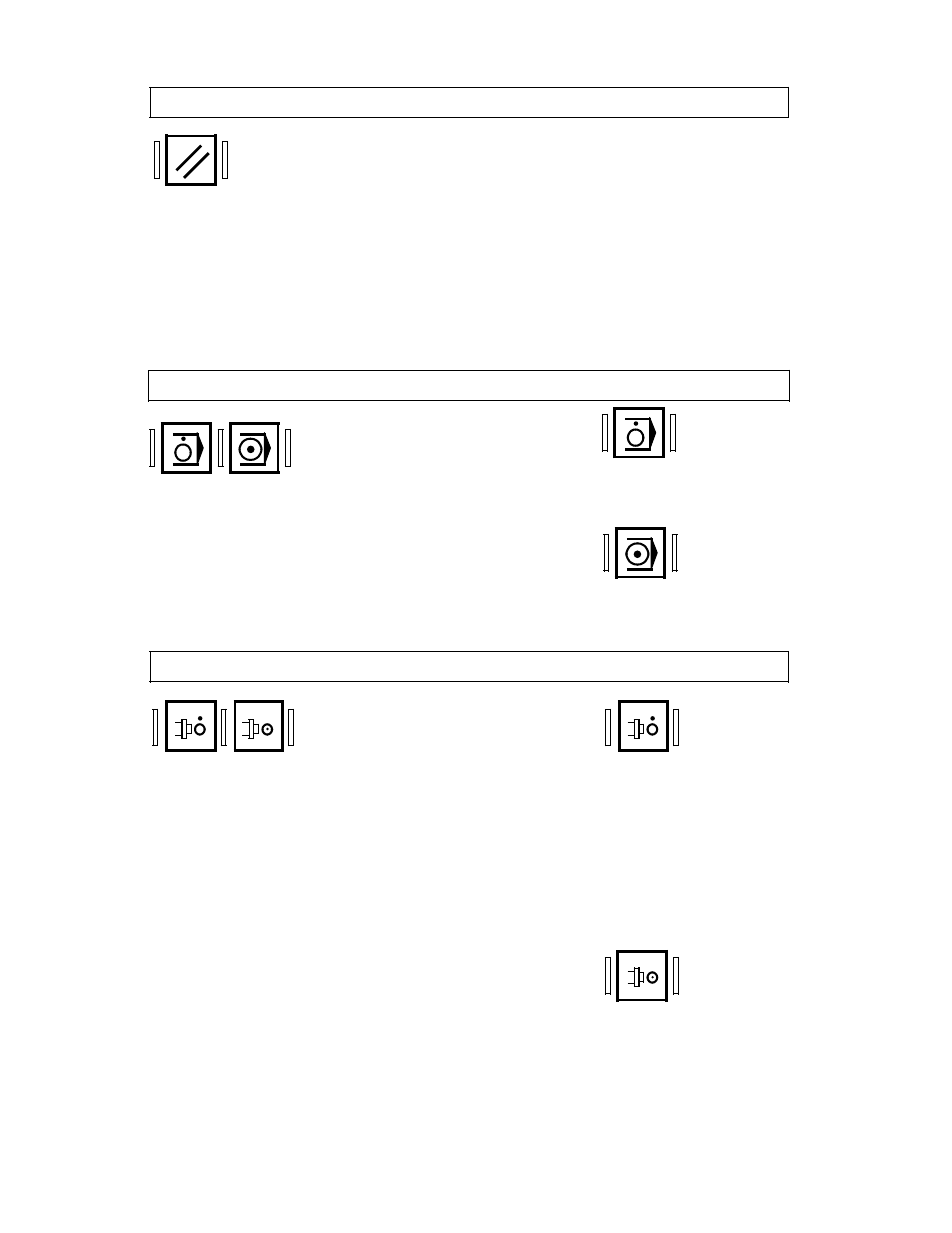

Reset

When you operate the ”Reset” key:

•

The current part program being processed is interrupted.

•

Diagnostics messages are cleared

(Alarm nos. 100 . . . . 2999)

•

The control is switched to the ”Reset” state:

–

the NC remains synchronized with the machine

–

all buffer and working memories are cleared (the part program

memory remains unchanged)

–

the control is in the reset condition and ready for a new program

start.

Program stop / program start (NC stop / NC start)

When you press the ”Program stop” key:

The program being processed is interrupted. You can continue the

operation by pressing ”Program start”.

When you press the ”Program start” key:

The part program called is re-started at the current block. In automatic

operation the overstored functions are transferred to the PLC.

Spindle stop / Spindle start

When you operate the ”Spindle stop” key:

Examples of the use of ”Spindle stop”

•

during operation in ”MDI AUTOMATIC” mode, a block with a fault is discovered

•

in ”JOG”, ”INC..”,”REPOS” modes, e.g. during repositioning to the contour

•

to change a tool

•

to input S, T, H, M functions during setting up

(overstore).

When you operate the ”Spindle start” key:

•

the spindle speed accelerates to the value specified in the part

program.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EP02

2-29

SINUMERIK 810T, GA3 (BN)