Siemens Sinumerik 810T User Manual

Page 271

4 Monitoring Functions

09.91

4.6 Listing of the alarms/alarm description

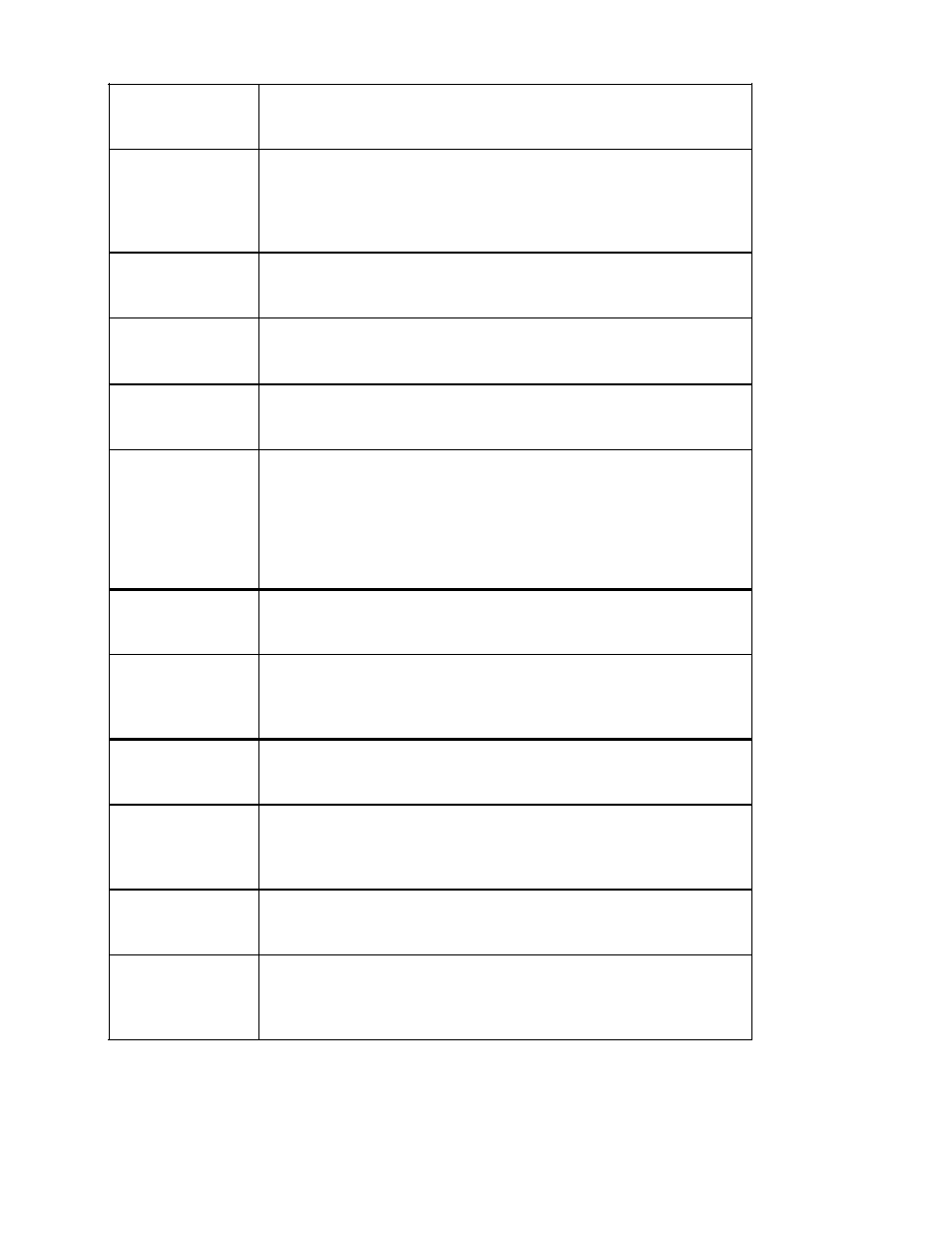

Alarm No.

Alarm Text:

3012

”Block not in memory”

Reason:

Remedy:

– The program has not been terminated with M02/M30/M17

– In a jump instruction (@ 100, 11y, 12y, 13y) the given block number

was not found in the given direction

– A @ instruction was programmed in the function “block transfer”.

As for alarm 3000

Alarm No.

Alarm Text:

3013

”Simulation disabled”

Reason:

Remedy:

When the appropriate machine data is set, graphic simulation (for

testing part programs) is only possible when a program is not being

simultaneously run on the machine.

Alarm-No.

Alarm Text:

3016

”External data input error”

Reason:

Effect:

Remedy:

During external data input from PLC to NC:

– the code is incorrect

– the value is too large

– the dimension identifier is invalid

– the option is not fitted

Data transfer is interrupted

– Check PLC program or call Service

Alarm-No.

Alarm Text:

3017

”Part prog. no. occurs twice”

Reason:

Effect:

Remedy:

There is a program present on the cycles EPROM submodule, which

is also present in the part program (RAM) memory.

Inhibiting of NC START

Delete the program in RAM

Alarm-No.

Alarm Text:

3018

”Distance from contour too great (NC MD9)”

Reason:

Effect:

Remedy:

After repositioning to a circular contour, the distance between the axes

and the contour is too great.

The NC inhibits ”Program start”.

Retraverse to the contour to reduce the distance.

Alarm-No.

Alarm Text:

3019

”Option RS232C (V.24) not available”

Reason:

Remedy:

The 2nd RS232C (V.24) interface has been started, either from the

PLC or with the softkey, but the option is not fitted.

– Transfer data via the 1st RS232C (V.24) interface.

– Retrofit option C62 (2nd RS232C (V.24) interface)

4-28

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EP02

SINUMERIK 810T, GA3 (BN)