Siemens Sinumerik 810T User Manual

Page 256

4 Monitoring Functions

01.93

4.6 Listing of the alarms/alarm description

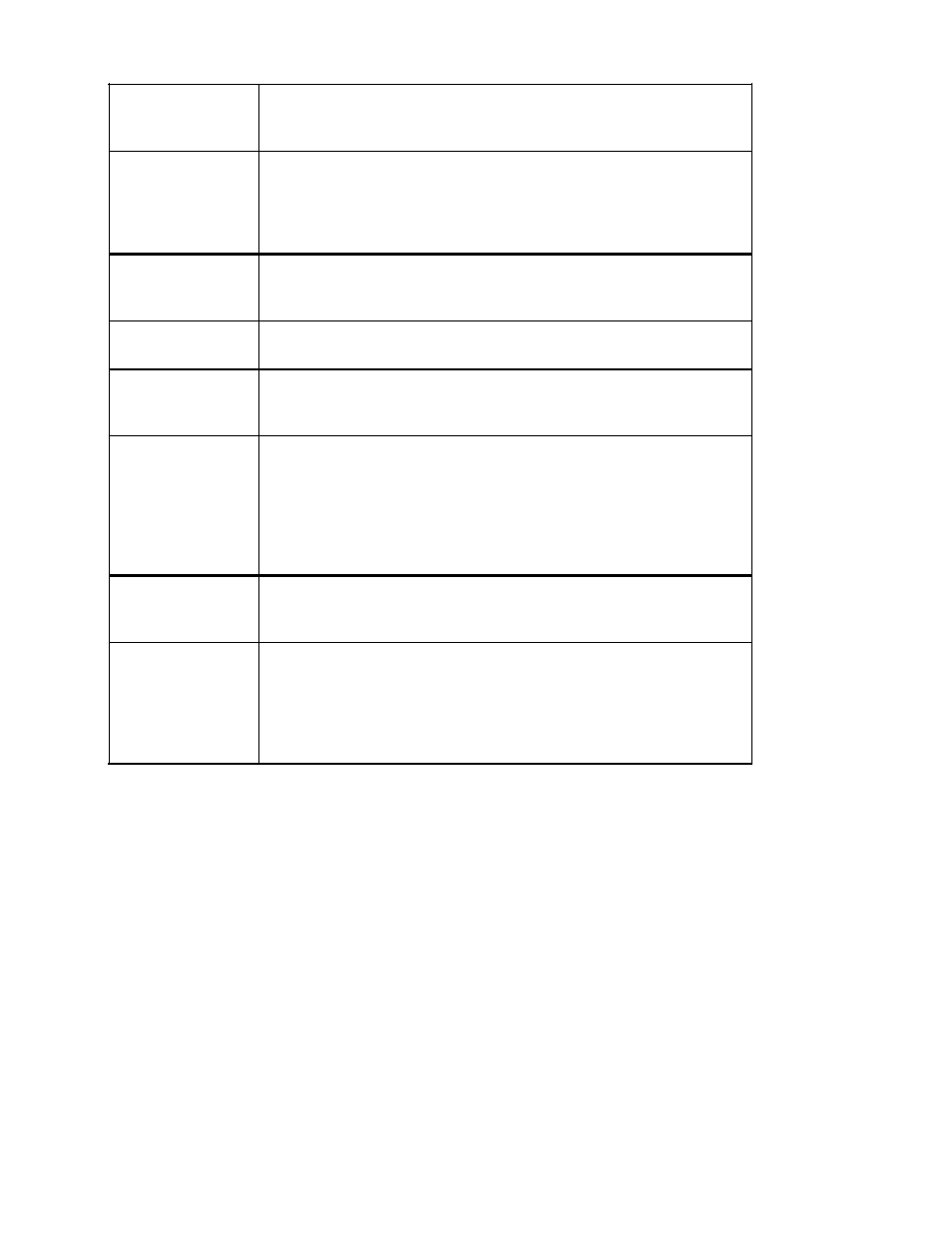

Alarm No.

Alarm Text:

184

*

”Stop behind ref. point”

Reason:

Effect:

Remedy:

When traversing to reference point, the axis was stopped between the

reference cam and the zero mark of the measuring system

– Inhibiting of NC START

– Reference point not reached

Approach reference point again

Alarm No.

Alarm Text:

196

*

”Follow-up /park for axis”

Reason:

Remedy:

Spindle is not active as rotary axis.

Switch spindle to axis mode.

Alarm No.

Alarm Text:

2000

”Emergency Stop”

Reason:

Effect:

Remedy:

The EMERGENCY STOP signal is output from the PLC to the NC

– Inhibiting of NC START

– Operation is brought to a defined stop

– Servo enable is removed

– Follow up operation

Check to see if the EMERGENCY STOP cam was traversed to, or if

the EMERGENCY STOP switch was operated

Alarm No.

Alarm Text:

2030

”Wrong path increment”

Effect:

Remedy:

Explanation:

–

Locking of NC START

–

Locking of NC Ready

–

Machining stop

Check G06 block, recalculate and correct if necessary.

Distance-to-go contains an incorrect value which does not match the

programmed contour

_______

”*” stands for : ”0” = axis 1, ”1” = axis 2, ”2” = axis 3, ”3” = axis 4, ”4” = axis 5

4-14

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EP02

SINUMERIK 810T, GA3 (BN)