13 scratching, Q – x – z +x +q +z – Siemens Sinumerik 810T User Manual

Page 241

3 Operating Sequences

09.91

3.2.13 Scratching

3.2.13 Scratching

If there is a breakdown during the program process, e. g. a tool breakage, you must leave the

contour by changing to the ”JOG” or ”INC 1 ... INC 10 000” operating mode, in order to

change the tool.

After entry of the new tool length compensation (the cutter radius remains unchanged) you

traverse the tool to return to any point on the contour - within the interrupted block -

(”Scratching”).

Prerequisite :

A tool change has been carried out;

The control is in ”JOG” mode:

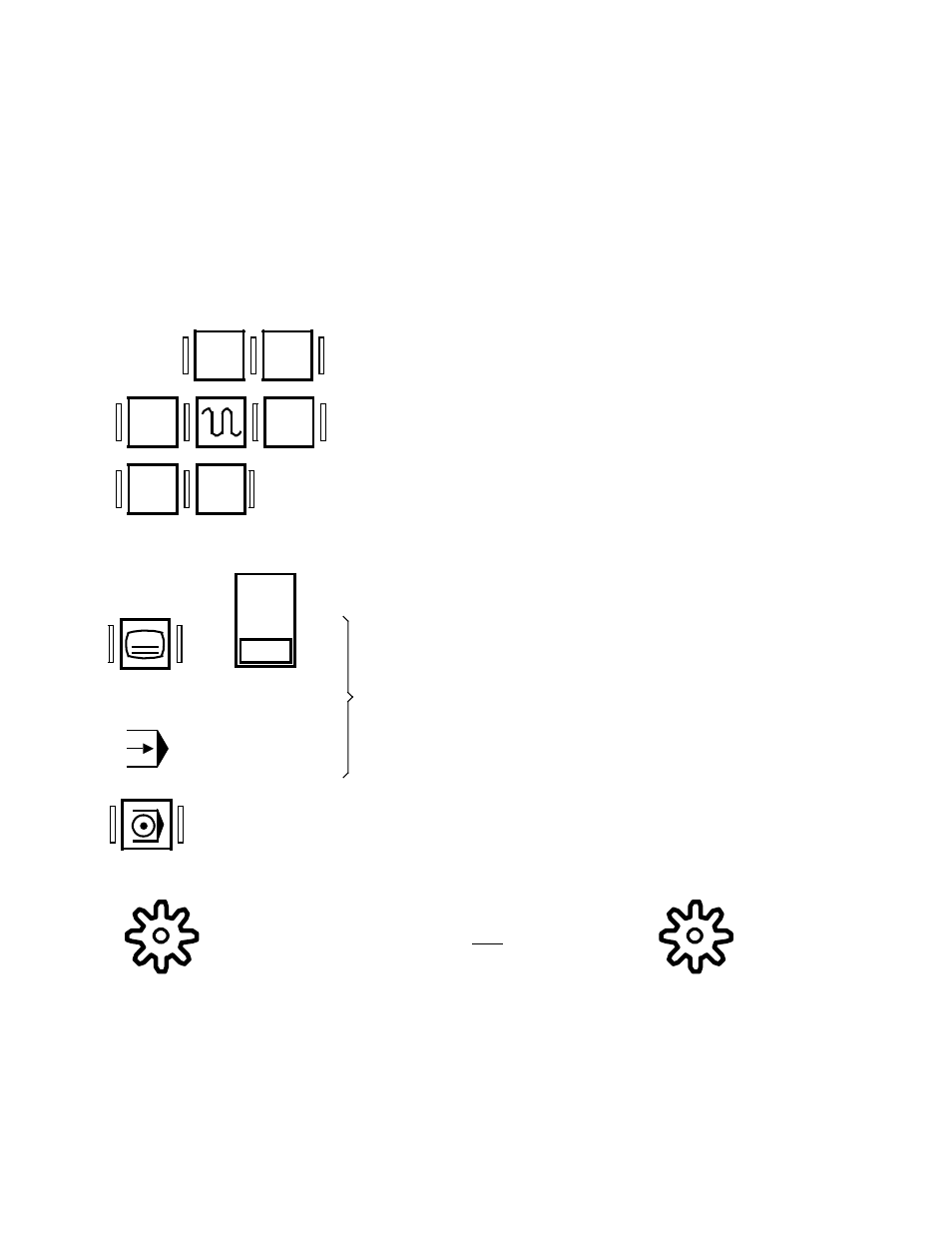

Using the direction keys, now traverse to any point

that lies within the interrupted block.

Using the operating mode selection key (integrated

machine control panel) and softkey ...

or

... with this symbol on the operating mode selector

switch (external machine control panel) select

”AUTOMATIC” mode.

Resume the program process with ”Program start”.

AUTO-

MATIC

and

or

– Q

– X

– Z

+X

+Q

+Z

Sequence of operation

In a block with circular interpolation (G02, G03) the

scratching must take place in a very narrow range.

This range is defined in machine data.

Standard definition via MD ”9”.

If the range is exceeded: alarm 3018:

“Distance from contour too great (NC MD9)”.

3-134

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EP02

SINUMERIK 810T, GA3 (BN)