Siemens Sinumerik 810T User Manual

Page 104

3 Operating Sequences

01.93

3.1.4 Tool offset

4

Diameter/radius

2

L1 Geometry

Under points P = ”2” and P = ”3”, you enter

the geometry values of the turning tools into

the input field

Under point P = ”4” you enter the value of the

cutter radius.

3

L2 Geometry

2.

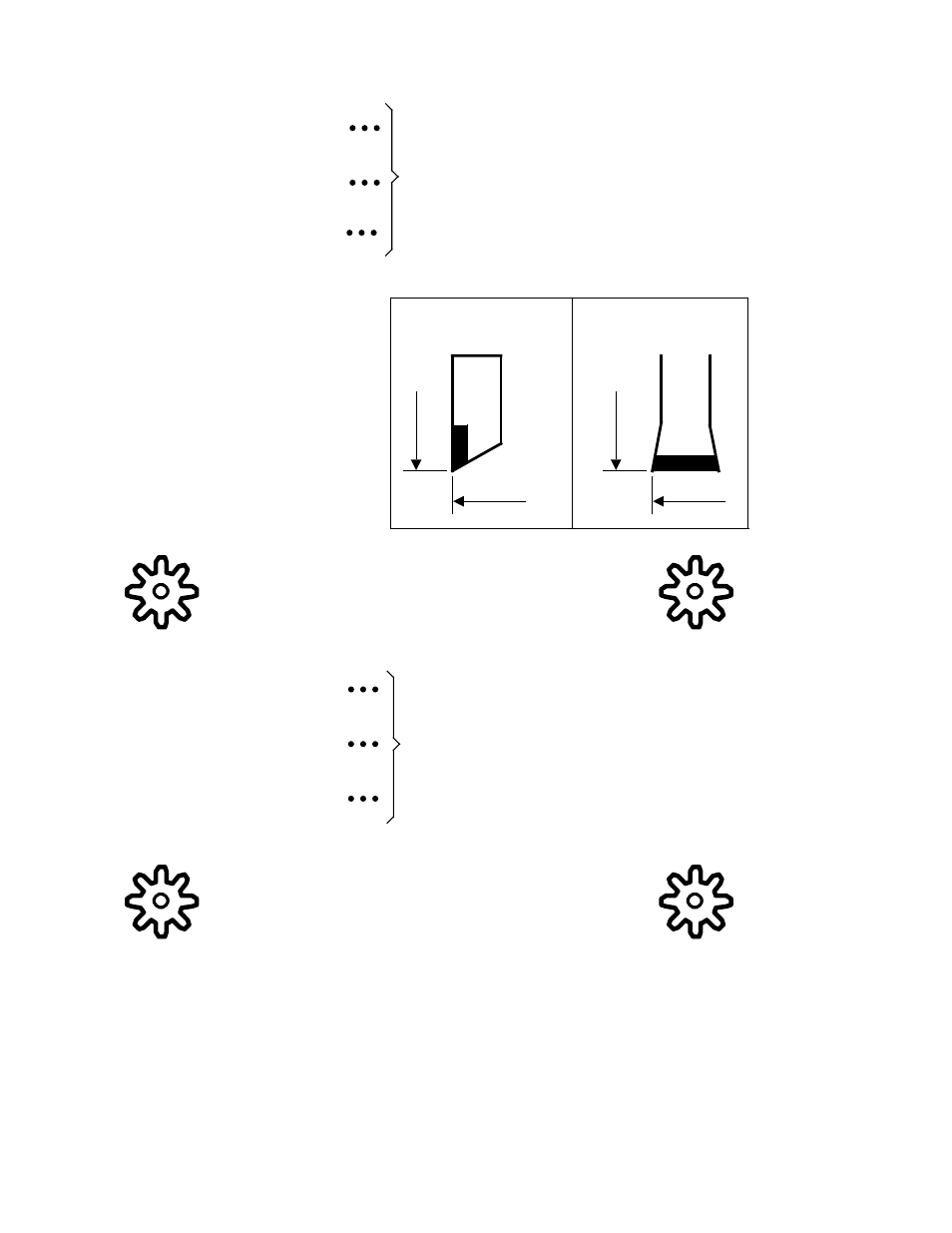

Grooving tool

(left tip)

1.

Turning tool

Facing tool

L2

L1

L2

L1

Geometry values of the available

tool types:

The input of tool geometry values can be inhibited with

a key switch.

5

L1 Wear

Under points P = ”5” to P = ”7”, you can (not

obligatory) enter the wear data of the tools into

the input form.

The machine tool manufacturer can set the

maximum wear input to ± 0.999 mm.

6

L2 Wear

7

Diameter/radius

The input of tool wear data can be inhibited by means

of a key switch!

3-6

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0EP02

SINUMERIK 810T, GA3 (BN)