Discrete i/o – Rockwell Automation 2711-ND3 PanelBuilder v2.60 Software User Manual User Manual

Page 65

4–9

Communications Overview

Publication 2711-6.0

Discrete I/O addresses communicate directly with the controller and

provide faster updates than block transfers. Discrete I/O is

recommended for:

•

Push buttons (for rapid response times)

•

Any critical values that you want updated immediately

A PLC rack has 128 discrete I/O points (8 input words/8 output

words). If additional rack space is needed for an application, use

block transfers.

You must assign a read or display tag to an output address. If you

assign a read tag to an input address, a validation error occurs. The

read and write tags must have different tag names and reference

different addresses.

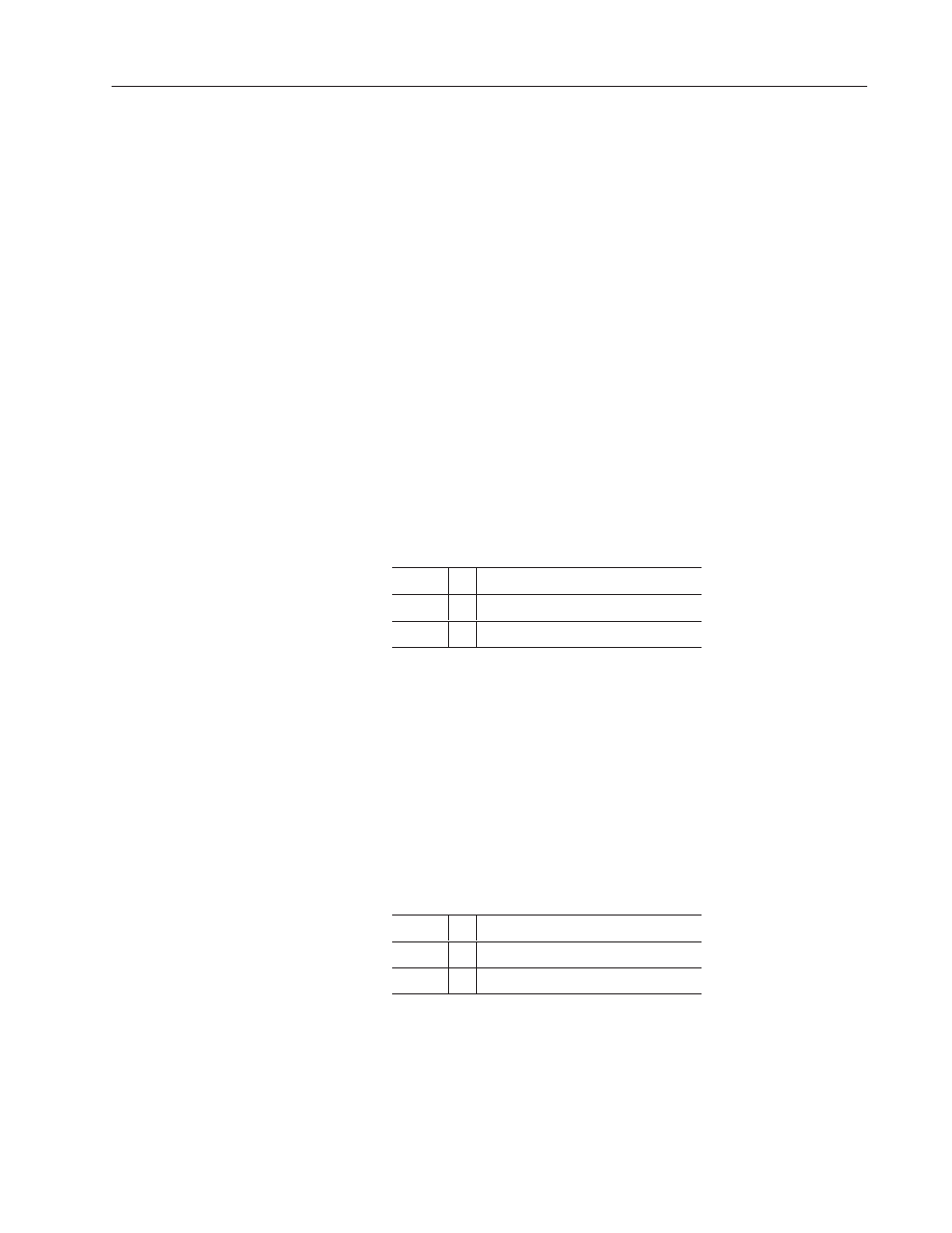

Discrete I/O Addressing for 1771-SN Scanners

The I/O addressing syntax for the 1771-SN Scanner (Series A) is:

I:YYW/BB

O:YYW/BB

where:

YY

=

Rack number

W

=

Word or group address

BB

=

Bit address, 0-7, 10-17 octal

For example:

I:024/10

addresses input bit 10, Rack 2, Module 4.

Discrete Addressing for 1747-SN Scanner, Series A and B

The addressing syntax for the 1747-SN Scanner (Series A and B) is:

I:X.WW/BB

O:X.WW/BB

where:

X

=

Slot where 1747-SN is installed in rack

WW

=

Word address, 0 - 31 decimal

BB

=

Bit address, 0-15 decimal

For example:

I:1.7/13

addresses input bit 13 of Word 7, Slot 1 (where 1747-SN Scanner

resides).

Discrete I/O