Application examples, 2 welding bar, 93xx – Lenze EVS9332xK User Manual

Page 366: Features, Speed−independent welding time, Adjustable welding time, Easy changeover in the event of material changes, Material−specific feed, Analog signals, Digital frequency output x10: virtual master value

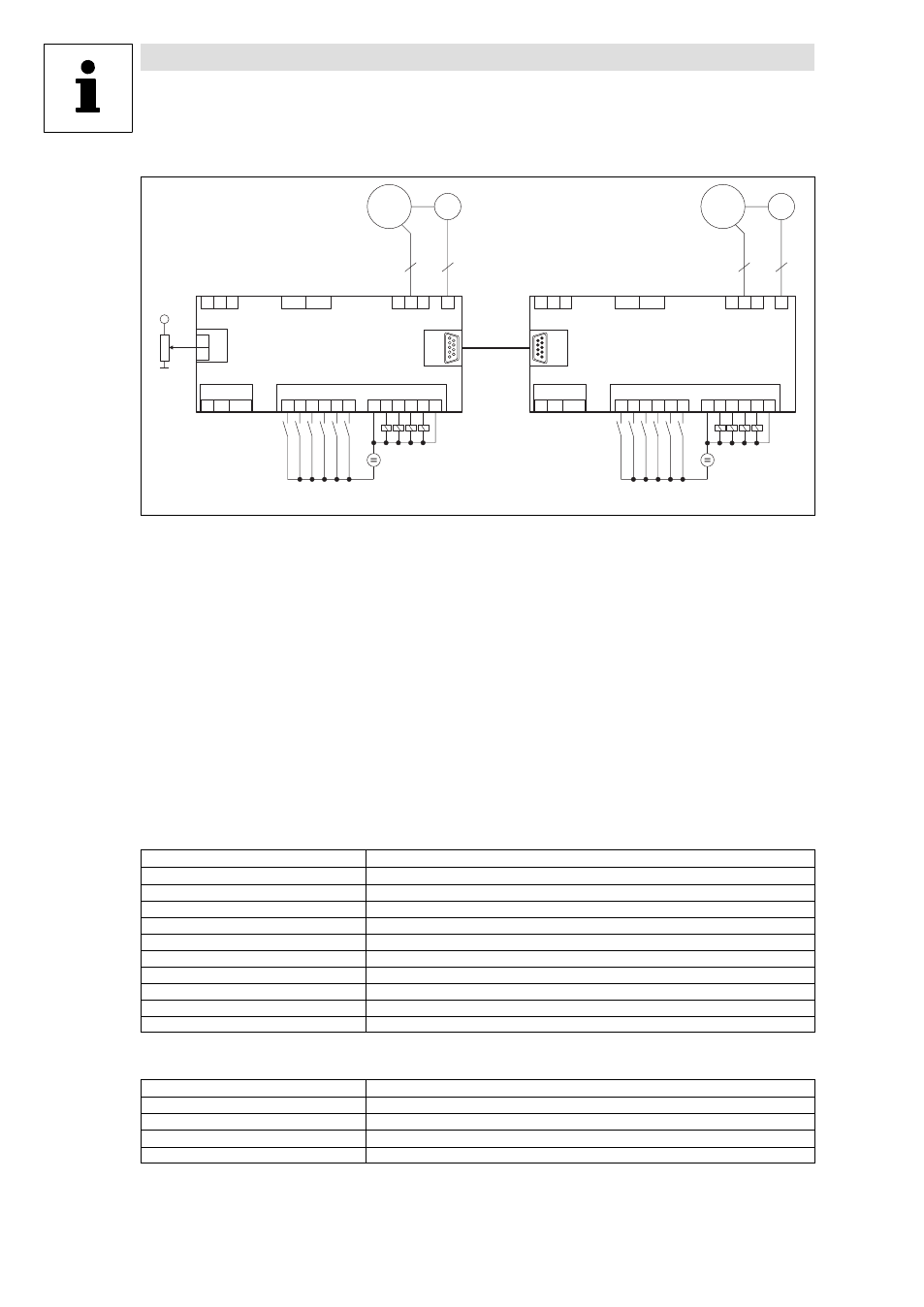

Application examples

4.2

Welding bar

4−6

l

EDSVS9332K−EXT EN 4.0

+UG

+UG

-UG

-UG

X4

X4

HI

HI

X5

X5

93XX

93XX

X10

-

-

DC 24V

DC 24V

M

M

RS

RS

3

3

9

9

+

+

±10V

1 X6

2

GND

GND

LO

LO

59

59

39

39

U

U

L1

2

3

0

1

L1

L2

L2

L3

L3

V

V

W

W

X7

X7

A1

A1

A2

A2

A3

A3

A4

A4

28

28

E1

E1

E2

E2

E3

E3

E4

E4

E5

E5

X9

9300kur046

Fig. 4−5

Wiring principle for the controllers

0

Controller for welding bar drive

1

Controller for feed drive

2

Speed setpoint

3

Virtual master value

RS

Resolver

Features

l

Speed−independent welding time

l

Adjustable welding time

l

Easy changeover in the event of material changes

l

Material−specific feed

l

Virtual master for coordination of feed and welding bar

Digital signals

Terminal

Function

X5/28

Controller enable

X5/E1

Selection of event profile (C1420)

X5/E2

Profile selection (see table for terminal layout)

X5/E3

Profile selection (see table for terminal layout)

X5/E4

Profile selection (see table for terminal layout)

X5/E5

Error reset (TRIP reset) / profile acceptance

X5/A1

Error (TRIP)

X5/A2

Following error limit reached

X5/A3

Ready for operation (RDY)

X5/A4

Welding time error

Analog signals

Terminal

Function

Analog input 1: X6/1, X6/2

Setpoint of the virtual master

Analog input 2: X6/3, X6/4

Not assigned

Analog output 1: X6/62

Actual speed

Analog output 2: X6/63

Actual torque

Digital frequency output X10: virtual master value