Application examples, 1 replacement of a mechanical cam – Lenze EVS9332xK User Manual

Page 364

Application examples

4.1

Replacement of a mechanical cam

4−4

l

EDSVS9332K−EXT EN 4.0

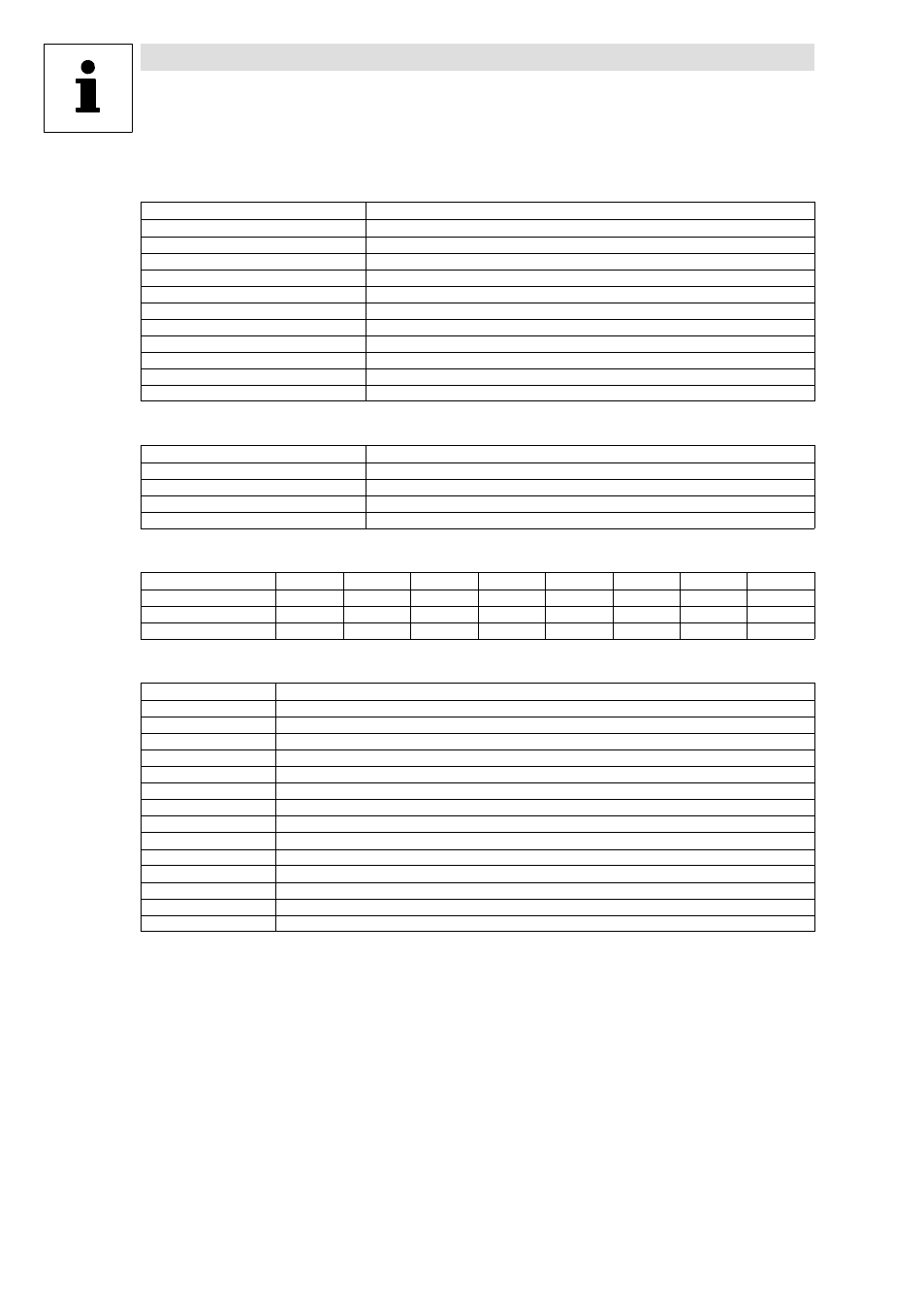

Digital signals

Terminal

Function

X5/28

Controller enable

X5/E1

Selection of event profile (C1420)

X5/E2

Profile selection (see table for terminal layout)

X5/E3

Profile selection (see table for terminal layout)

X5/E4

Profile selection (see table for terminal layout)

X5/E5

Error reset (TRIP reset) / profile acceptance

X5/A1

Error (TRIP)

X5/A2

Following error limit reached

X5/A3

Ready for operation (RDY)

X5/A4

Following error warning limit reached

Analog signals

Terminal

Function

Analog input 1: X6/1, X6/2

Not assigned

Analog input 2: X6/3, X6/4

Not assigned

Analog output 1: X6/62

Actual speed

Analog output 2: X6/63

Actual torque

Terminal layout for profile selection

Profile No.

0

1

2

3

4

5

6

7

X5/E2

0

1

0

1

0

1

0

1

X5/E3

0

0

1

1

0

0

1

1

X5/E4

0

0

0

0

1

1

1

1

Application−specific codes

Code

Function

C0425

Encoder constant of the master value

C1420

Selection of the event profile (X5/E1 = HIGH)

C1380/1

Hysteresis of following error evaluation

C1380/2

Hysteresis of following error warning

C0472/1

Stretching/compression of X axis (100% = no stretching/compression)

C0472/2

Influence of speed feedforward control

C0472/3

Influence of torque feedforward control

C0472/4

Reduction factor for following error warning (warning limit = C0472/4 x C1477/2)

C0472/9

Stretching/compression of Y axis (100% = no stretching/compression)

C0472/10

Torque limit value

C1476/1

Angle trimming in X direction

C1476/16

Touch−probe position in X direction

C1477/1

Angle trimming in Y direction

C1477/2

Following error limit (in s_units)

For the generation of profile data and its transmission to the controller please refer to the System

Manual.