Configuration, Basic configurations – Lenze EVS9332xK User Manual

Page 26

Configuration

Basic configurations

2.2.5

Operation with position storage (C0005 = 12000)

2−12

l

EDSVS9332K−EXT EN 4.0

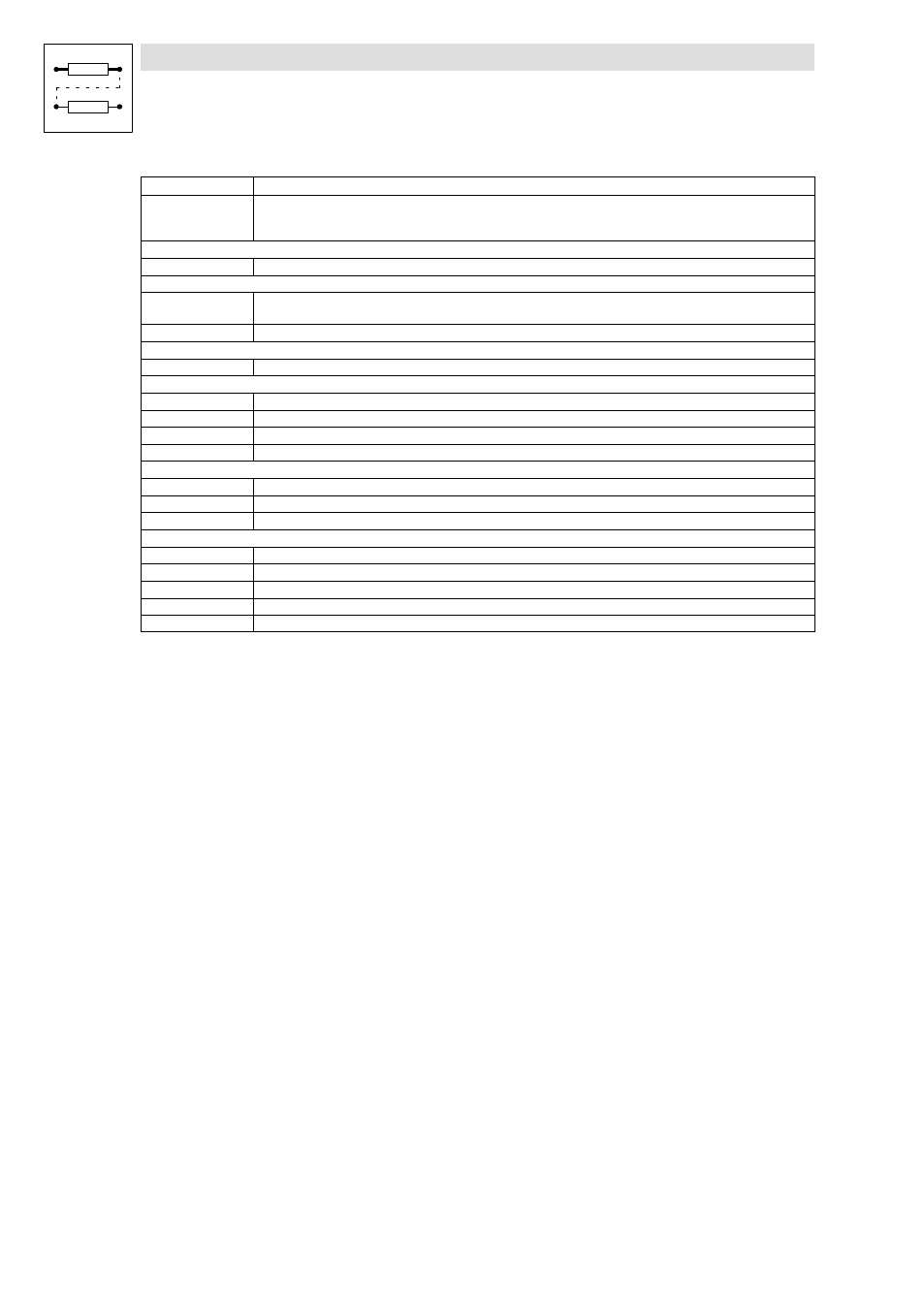

Code

Description

C0005 = 12000

With this configuration and an absolute feedback system (resolver or Sin/Cos absolute value encoder), the position

values of the motor shaft can be stored when switching off the mains. When the mains is switched on again, the actual

values are compared to the stored values.

·

Master value

C0425

Encoder constant of the master value

·

Cam profile data

C1300 ... C1317

The cam profile data are determined by the generation of the profile. Usually, they do not have to be changed

separately.

C1420

Determines the profile to be used when an event input is activated (X5/E1 = LOW).

·

Contouring error evaluation

C1380/1 and C1380/2 Determine comparison window and hysteresis of the contouring error evaluation.

·

Adjustment values

C0472/2

Influence of speed precontrol

C0472/3

Influence of torque precontrol

C1477/2

Contouring error limit (in s/units)

C0472/4

Reduction factor for contouring error warning; warning limit = C0472/4 × C1477/2

·

Profile influence

C1472/1

Stretching/compression of X−axis (100 % = no stretching/compression)

C1476/1

Angle trimming in X−direction

C1477/1

Angle trimming in Y−direction

·

Position memory

C1430/1, C1430/2

Tolerance window of the comparison functions

C1431

Determination of values to be stored (master and/or actual value)

C1476/16

TOUCH−PROBE position in X−direction

C0472/9

Stretching/compression of Y−axis

C0472/10

Torque limit value