32 speed optimization, 33 reference parameters – Siemens 440 User Manual

Page 192

Parameter Description

Issue 01/06

MICROMASTER 440 Parameter List

192

6SE6400-5BB00-0BP0

3.32 Speed

optimization

P1960

Speed control optimisation

Min: 0

CStat:

CT

Datatype: U16 Unit:

-

Def:

0

P-Group: MOTOR

Active: first confirm

QuickComm.: No

Max: 1

The drive should be set into a vector mode (P1300 = 20 or 21) to carry out speed controller optimisation.

When speed controller optimisation is enabled (P1960 = 1) the warning A0542 will become active.

When the drive is next started it will do the optimisation tests. The drive will accelerate the motor to 20 % of

P0310 (rated motor frequency) using the ramp up time P1120 and then under torque control go to 50 % of

P0310 (rated motor frequency). The drive will then ramp back down to 20 % using the ramp down time

P1121. This procedure is repeated several times and then average time taken. From this an estimation of

the inertia of the load on the motor can be derived. From this the inertia ratio parameter (P0342) and the Kp

gains for VC (P1460) and SLVC (P1470) are modified to give a response suitable for the measured inertia.

Possible Settings:

0 Disabled

1 Enabled

Note:

-

When the test is complete P1960 will be cleared to zero.

-

If there is a problem due to instability the drive may trip with an F0042 fault if a stable value has not

been obtained on the ramp up within a reasonable time.

-

It should be noted that the DC-link controller should be enabled whilst doing the test as otherwise

overvoltage trips maybe experienced. This will however depend on the ramp down time and the system

inertia.

-

The speed loop optimisation may not be suitable for some applications due to the nature of the test i.e.

accelerating under torque control from 20 % to 50 %.

3.33 Reference

parameters

P2000[3] Reference

frequency

Min: 1.00

CStat:

CT

Datatype: Float Unit:

Hz

Def:

50.00

P-Group: COMM

Active: first confirm

QuickComm.: No

Max: 650.00

Parameter P2000 represents the reference frequency for frequency values which are displayed/transferred

as a percentage or a hexadecimal value. Where:

-

hexadecimal 4000 H ==> P2000 (e.g.: USS-PZD)

-

percentage 100 % ==> P2000 (e.g.: ADC)

Index:

P2000[0] : 1st. Drive data set (DDS)

P2000[1] : 2nd. Drive data set (DDS)

P2000[2] : 3rd. Drive data set (DDS)

Example:

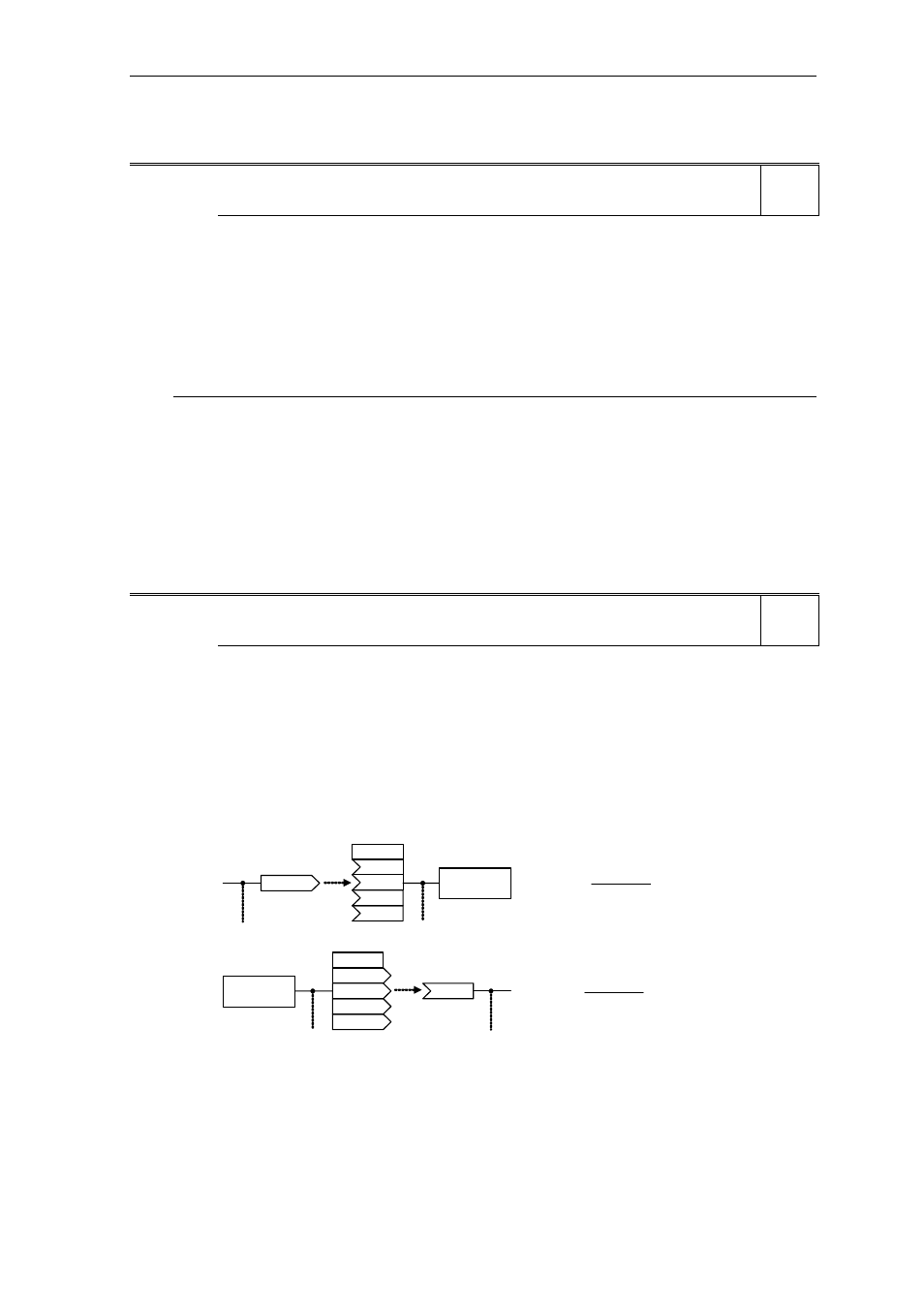

If a BICO connection is made between two parameters or alternatively using P0719 or P1000, the "unit" of

the parameters (standardized (Hex) or physical (i.e. Hz) values) may differ. MICROMASTER implicitly

makes an automatic conversion to the target value.

P1070

y[Hz]

2000

P

4000[Hex]

r2015[1]

y[Hz]

⋅

=

r2015

[0]

[1]

[2]

[3]

P2016

[0]

[1]

[2]

[3]

r0021

x[Hz]

y[Hex]

x[Hex]

]

Hex

[

4000

P2000[Hz]

r0021[Hz]

y[Hex]

⋅

=

USS-PZD

BOP link

USS-PZD

BOP link

Level

3

Level

2