Kv -300 – KEYENCE Visual KV Series User Manual

Page 214

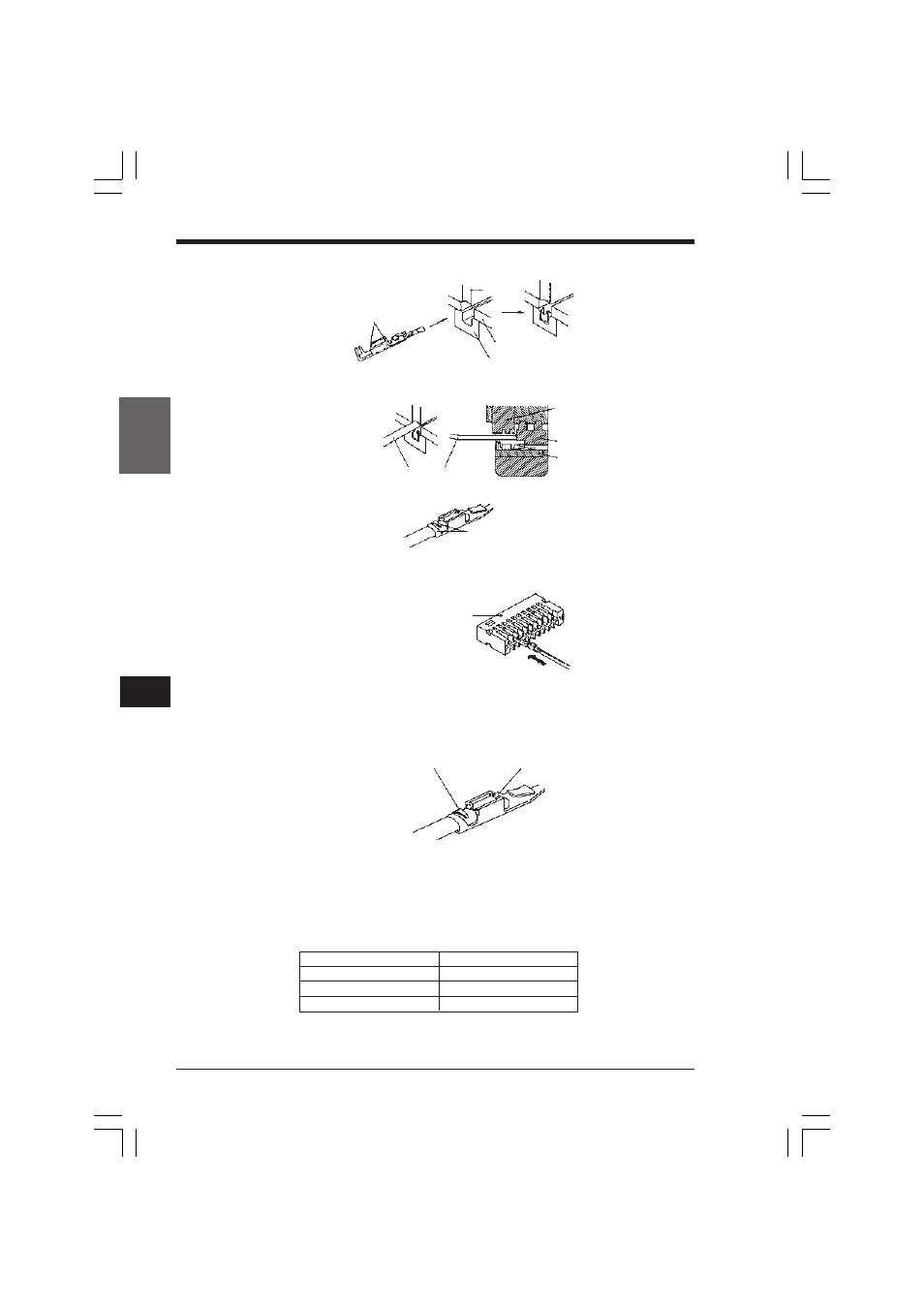

5.3 Module/Unit Connections

KV

-300

KV-10/80

5

Chapter 5 KV-300 Hardware

1-190

2. Insert the contact directly until it touches the contact holder.

3. Insert the cable directly to the end along the crimping slot.

4. Grip the handle until the contact clamp fully encircles the cable.

5. Gently pull the cable and remove the crimped contact from the contact holder.

Insert it into a housing containing no contact.

Crimping tool cautions

•

Choose an appropriate cable.

•

Cut the cable tip sharply so that no burrs remain. It is not necessary to peel back

the sheath.

•

After crimping, check the following:

•

The crimping tool is plastic and is designed to be lightweight. It may break if

excessive force is applied to the handle after crimping.

•

The precision mechanism of the crimping tool may malfunction if it is dropped or

jarred. Do not disassemble the tool.

•

The plastic material will melt upon contact with strong solvents such as acetone,

trichlene, or benzine. Do not allow solvents to contact the tool.

•

Even if no crimping tool is available, you may be able to solder the contact and

cable.

•

A flat cable can be used, as the connector conforms to the MIL Standard.

Crimping grooves

Crimping

punch

Cover

Guide

Cable

Cable

Crimping punch

Cover

Guide

The clamp should fully encircle the cable.

Housing with no contact

The clamp must fully

encircle the cable.

The cable must be inserted

completely into the contact.

Special crimping tool

Part no. OP-21734

34-pin connector

Part no. OP-23139

20-pin connector

Part no. OP-22185

Contacts (200)

Part no. OP-22186

KVHKA Chap 05.p65

08.3.11, 11:14 AM

190