Using the rotary motor window – Rockwell Automation 2098-UWCPRG Ultraware Software User Manual User Manual

Page 335

Rockwell Automation Publication 2098-UM001G-EN-P - February 2011

337

Creating Custom Motors Chapter 7

Using the Rotary Motor

Window

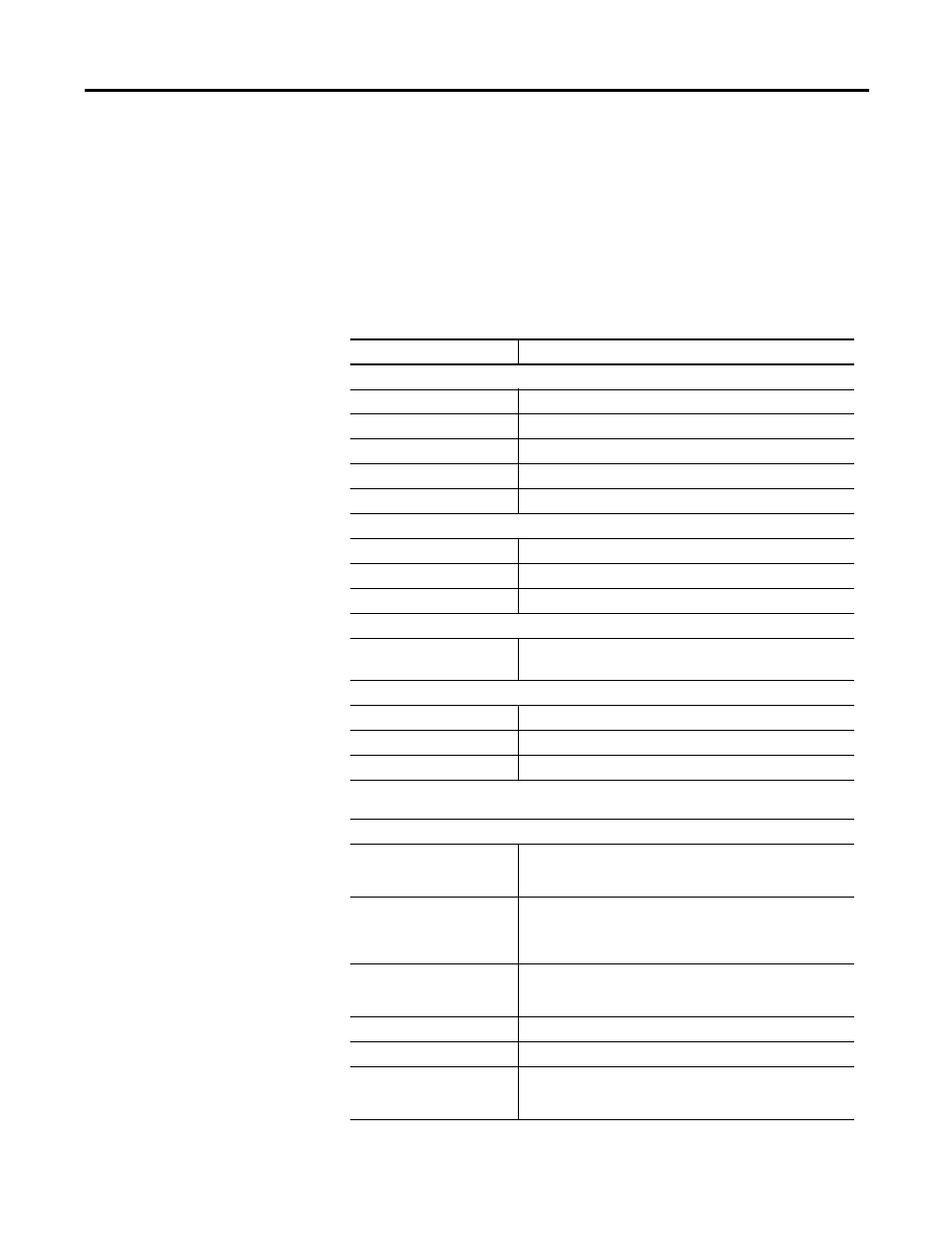

The Rotary Motor window configures a custom motor by entering motor

parameters, or to edit an existing motor's parameter set.

Standard motors are opened in a read-only mode. If a motor is duplicated, it

becomes a custom motor with a default model name consisting of the duplicated

motor's model with _copy n appended (for example, Std-Rotary_copy 1).

The following parameters can be entered and edited in the Rotary Motor

window.

Parameter Description

General

Model:

Model number or name up to 32 digits in length

Standard Motor:

Checked if standard Rockwell Automation motor.

Torque Constant:

0.00024…15.9998 N-m/A

Inertia:

0.00001…65535.999 Kg-cm^2

Poles per Revolution:

even numbers from 2…100

Electrical

Resistance:

0.0039…255.996 Ohms

Inductance:

0.0039…255.996 mH

Rated Voltage:

100…1000 Volts

Flux Saturation

1/8, 1/4, 3/8, 1/2, 5/8, 3/4, 7/

8, and Peak Current

0.000…1.000

Set all flux saturation levels for custom motors to 1.000.

Ratings

Maximum Speed:

300…32767 rpm

Intermittent Current:

0.008…255.99 Amps

Continuous Current

0.008…255.99 Amps

Note: All units relative to current (Amps) are based upon 0 to Peak of the sine wave (not RMS

units). Winding data values are phase-to-phase.

Feedback

Encoder Type:

The type of encoder provides motor feedback:

• Incremental

• Sine/Cosine

Commutation Type:

The type of commutation for the motor:

• Brush

• Trapezoidal

• Sinusoidal

Startup Type:

The start-up commutation algorithm for the motor:

• Self-Sensing

• Hall Inputs

Hall Input Offset:

0…359º

Lines Per Revolution:

100…64,000 lines

Integral Limits:

Check when feedback has integral limit switches. For example,

if the motor has built-in overtravel limits which are interfaced to

the Ultra drive's Encoder (CN2) connector.