Rockwell Automation 2098-UWCPRG Ultraware Software User Manual User Manual

Page 174

176

Rockwell Automation Publication 2098-UM001G-EN-P - February 2011

Chapter 4 Configuring the Ultra5000 Drive

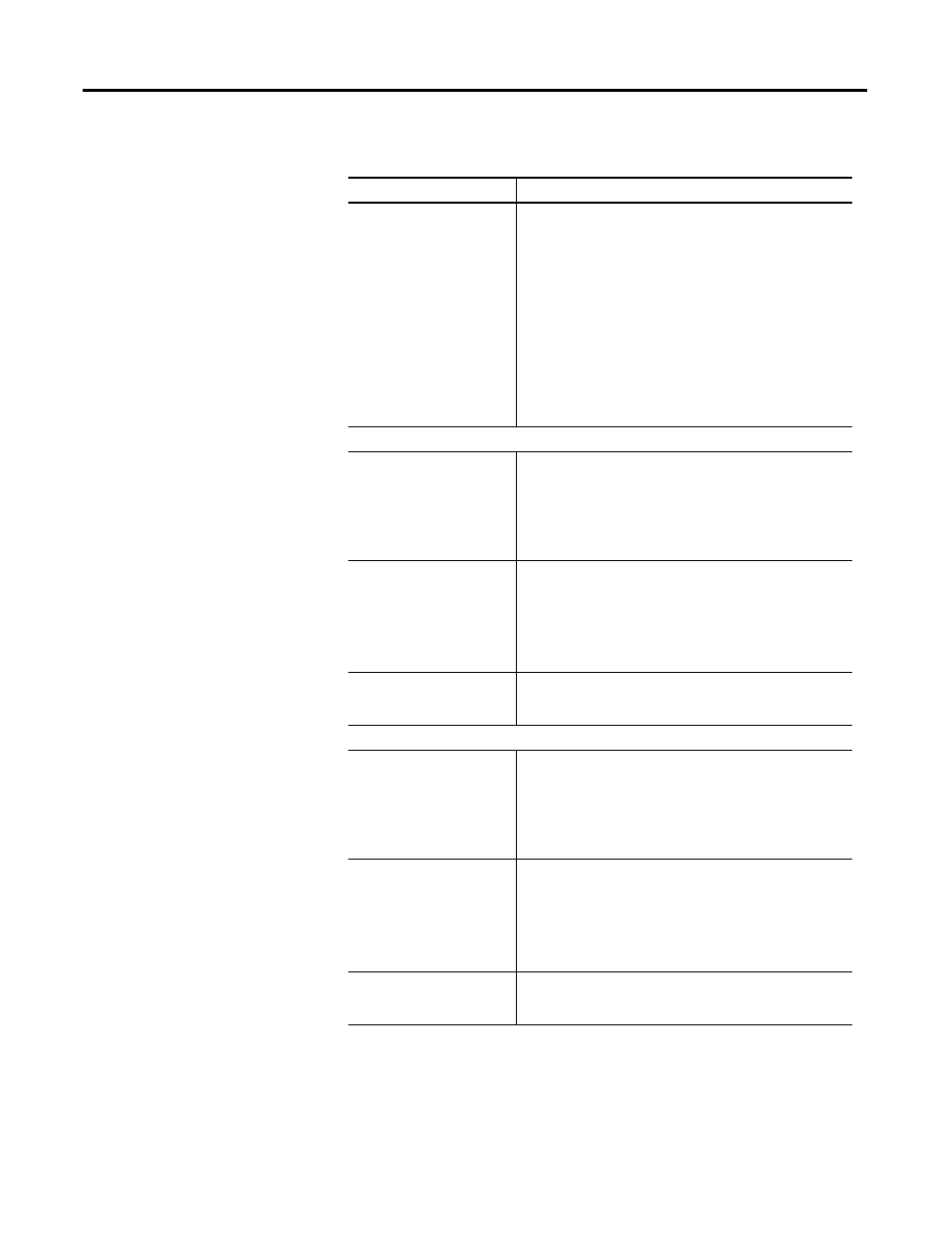

The following parameters can be entered and edited in the Encoders window.

Parameter Description

Motor Encoder Interpolation:

The amount of interpolation to be used with sine/cosine

encoders:

• 4

• x8

• x16

• x32

• x64

• x128

• x256

• x512

• x1024

For example, if a Stegmann encoder outputs 1024 cycles per

revolution and Encoder interpolation is set to x256, the drive will

use 262144 (1024 x 256) counts per revolution as the effective

feedback.

Motor Encoder

Polarity

The Motor Encoder’s polarity:

• Positive – turning the motor in a clockwise direction (as

viewed from the shaft end) increases the feedback position

(in counts).

• Negative – turning the motor in a clockwise direction (as

viewed from the shaft end) decreases the feedback position

(in counts).

Filter

The state of the motor encoder filter:

• Disabled

• Enabled

Note: The filter reduces the upper limit of the rate at which

feedback pulses are recognized. You man need to enable

feedback in a noisy environment, or when a long encoder cable

is used.

Fault Mode

The state of fault checking for the motor encoder at powerup:

• Disabled

• Enabled

Master Encoder

Polarity

The Master Encoder’s polarity:

• Positive – turning the motor in a clockwise direction (as

viewed from the shaft end) increases the feedback position

(in counts).

• Negative – turning the motor in a clockwise direction (as

viewed from the shaft end) decreases the feedback position

(in counts).

Filter

The state of the master encoder filter:

• Disabled

• Enabled

Note: The filter reduces the upper limit of the rate at which

feedback pulses are recognized. You man need to enable

feedback in a noisy environment, or when a long encoder cable

is used.

Fault Mode

The state of fault checking for the master encoder at powerup:

• Disabled

• Enabled