Festo Электромотор MTR-DCI User Manual

Page 260

B. Reference – Festo Handling and Positioning Profile (FHPP)

B-42

Festo P.BE-MTR-DCI-CO-EN en 1209a

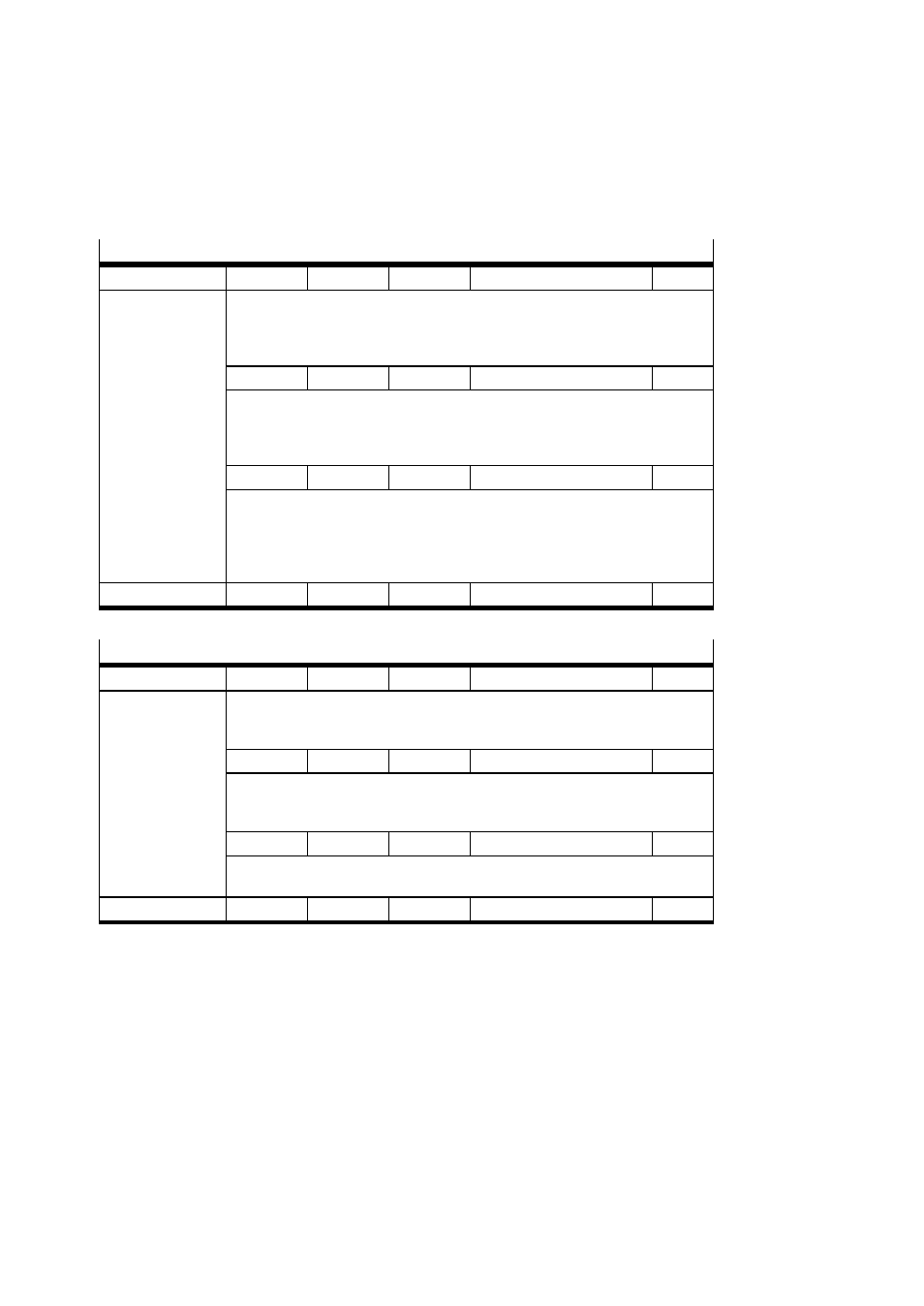

Gear Ratio

FHPP

1002

1, 2

Array

uint32

rw

Description

Ratio of the internal motor revolutions to the external revolutions of the drive

shaft of the MTR-DCI. The values are set fixed depending on the internal gear

(see type plate of the MTR-DCI).

Gear ratio = motor revolutions / spindle revolutions

Motor revolutions 1002

1

uint32

rw

Internal motor revolutions (gear ratio - counter)

Gear G7: Fixed: 27 (0x1B)

Gear G14: Fixed: 3969 (0xF81)

Gear G22: Fixed: 1710 (0x6AE)

Shaft revolutions 1002

2

uint32

rw

External revolutions of the drive shaft of the MTR-DCI

(gear ratio – denominator).

Gear G7: Fixed: 4 (0x04)

Gear G14: Fixed: 289 (0x121)

Gear G22: Fixed: 77 (0x4D)

CANopen / CI

6091h

01h, 02h

Array

uint32

rw

Feed Constant

FHPP

1003

1, 2

Array

uint32

rw

Description

The feed constant specifies the path (= feed) which the slide traverses when

the drive shaft of the linear axis makes one revolution (feed constant = shaft

revolution).

Feed 1003

1

uint32

rw

Specification of feed (feed constant - counter) in [μm].

When known axis types are selected on the control panel or in FCT, the value

is entered automatically.

Shaft revolutions 1003

2

uint32

rw

Feed constant - denominator.

Fixed: 1 (0x01)

CANopen / CI

6092h

01h, 02h

Array

uint32

rw