Festo Электромотор MTR-DCI User Manual

Page 194

6. Diagnostics and error display

6-10

Festo P.BE-MTR-DCI-CO-EN en 1209a

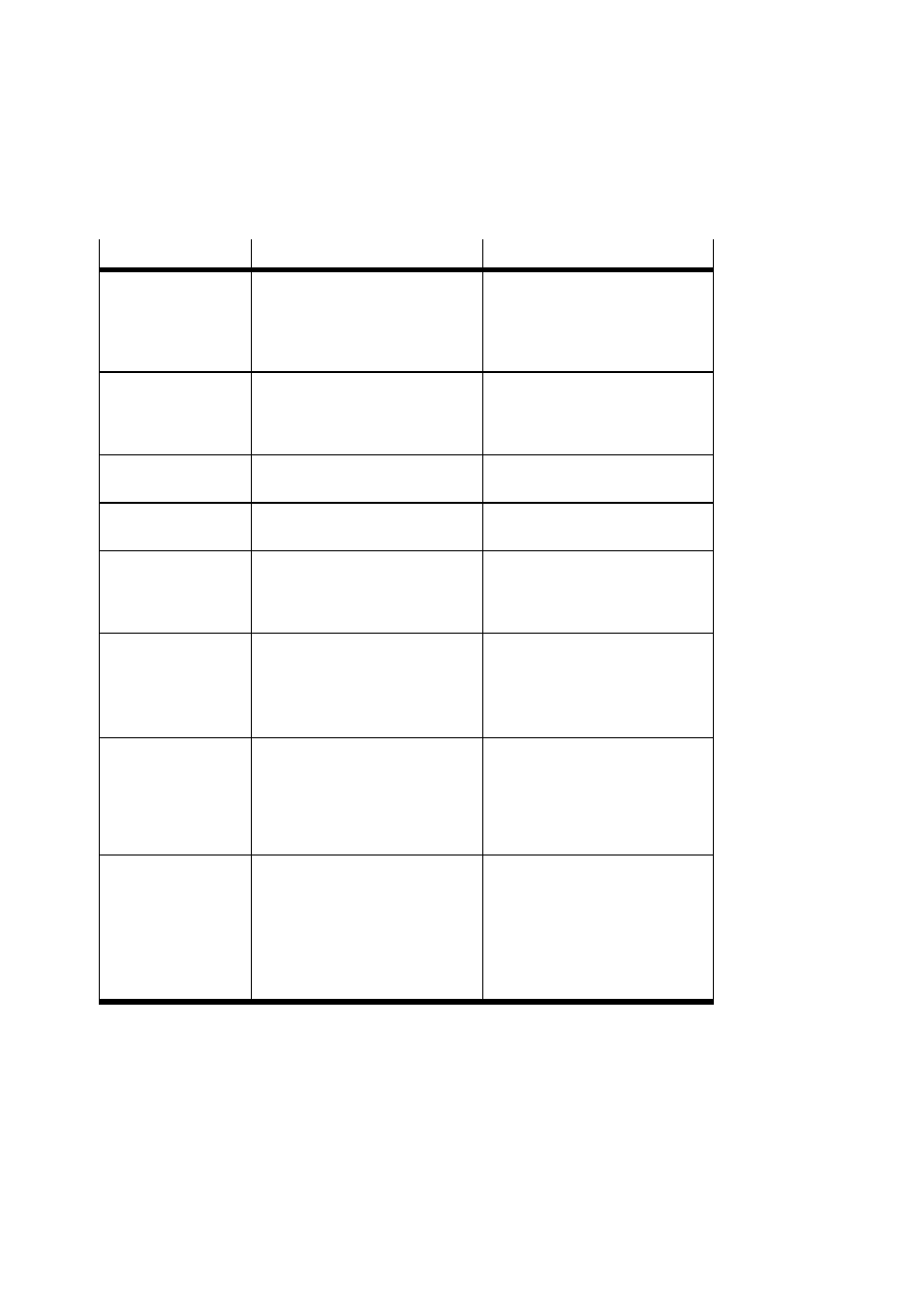

Fault

Possible cause

Remedy

CAN-BUS INIT NO

PARAMETER ERROR

Essential bus parameters not set.

– MTR-DCI not on the bus.

•

Set bus parameters (see sec-

tion 5.2.7):

– CAN Node-ID

– CAN bit rate

– CAN profile

CAN-BUS NO EXT. SUP-

PLY VOLTAGE

External CAN supply missing (only if

parameterised, see section 4.5.6,

Tab. 4/10 or object 2FF6h, sec-

tion C.3.4).

•

Check external CAN supply (see

section 3.6 or

•

Set internal CAN supply (see sec-

tion 5.2.7)

HARDWARE ERROR

Device fault (EEPROM defective, or

user data destroyed)

•

Contact Festo Service.

I2t-ERROR

Current monitoring i

2

t.

– The drive is blocked

•

Check the mechanical system of

the drive.

HOMING ERROR

Error during homing

– Homing run interrupted

– Reference switch defective

•

If necessary, check the function of

the reference switch.

•

It is essential that you repeat

homing.

LOAD-POWER-DOWN

Voltage monitoring

– Load voltage too low

MTR-DCI 32/42/52: U < 18 V

MTR-DCI 62: U < 34 V

– Voltage drops under load

•

Check the power supply:

– Power supply unit too weak?

– Supply line too long?

MOTOR STOP

Error during the positioning proced-

ure

– A positioning procedure is dis-

continued on the control panel

with EMERG.STOP (Taste

”Menu”).

•

Acknowledge the error on the

control panel with ”Enter”

OVERHEATING

Overheating

(Operating temperature > 80 °C).

– Temperature of power output

stage too high.

– Ambient temperature too high

•

Check:

– That the limits are complied

with (motor characteristic

curves),

– the mechanical system e.g. for

sluggishness.

•

If necessary, reduce the ambient

temperature.