IAI America RCM-101-USB User Manual

Page 62

5. Editing Position Data on CON Controllers and Older Models

50

(4) Positioning (test operation mode)

You can move the axis to the position corresponding to the cursor row in the position data input area.

The moving speed is calculated by multiplying the speed set in the position data input area with the speed

factor. (The speed factor can also be set by the track bar.)

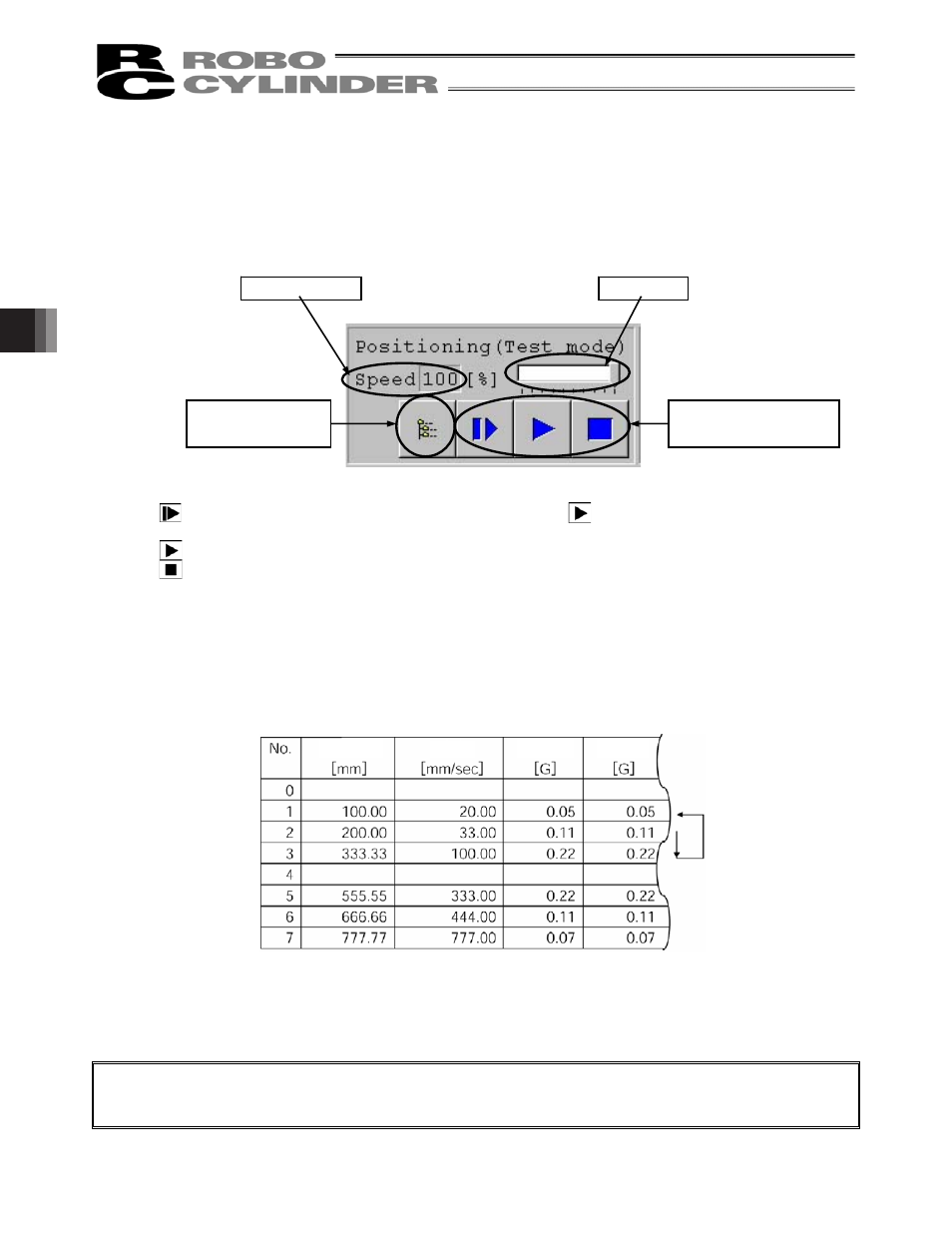

Fig. 5.19 Positioning

Clicking

(step) will move the axis by one position, while clicking

(continuous move) will cause the axis

to move continuously by looping within the block of specified position data.

Clicking

again while the axis is moving continuously will stop the axis when it reaches the next position.

Clicking

will stop the axis (the axis will start decelerating the moment the button is clicked and continue to

decelerate until it finally stops.)

* What is a continuous move?

If a continuous move command is issued at position No. 2 when the position table is set as follows, the actuator

will operate continuously through a group of positions where data is available (= until the position immediately

before one where no data is registered (whose data fields are empty)), starting from the position at which the

command is issued. In this example, the actuator will operate from position No. 2 Æ No. 3 Æ No. 1 Æ No. 2,

and so on.

* If the data loaded from the controller has been changed, write the modified data again to the controller

beforehand.

* While this mode is active, data cannot be entered in the jogging/inching control groups or point data input

area.

Ɣ

When PCON, ACON, SCON, MSCON, ERC2 and ERC3 are connected, the maximum speed becomes the

safety speed of 250 mm/sec or less if the MANU operation mode is set to the teach mode 1 (safety speed

effective).

Speed factor

Track bar

Step, continue and stop

buttons from the left

Multiple axes

simultaneous start

Position

Velocity

Acceleration

Deceleration