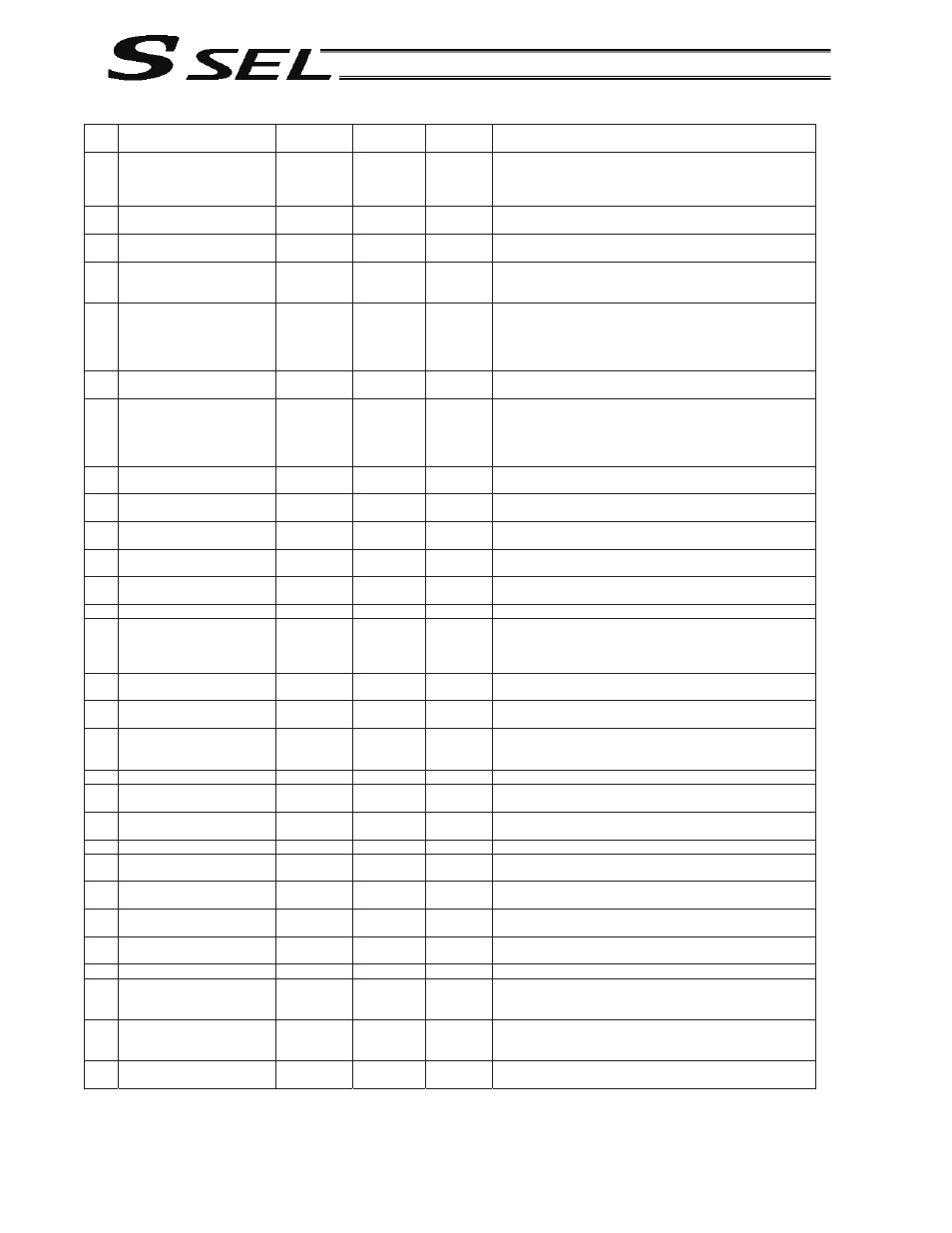

413 appendix axis-specific parameters – IAI America SSEL User Manual

Page 435

413

Appendix

Axis-Specific Parameters

No Parameter

name

Default value

(Reference)

Input range

Unit

Remarks

26 (Phase-Z

evacuation

distance at absolute home

return (old))

1000

0 ~ 99999

0.001 mm

Evacuation distance from the actual phase-Z position

(Positive value = Applied in the direction of moving away

from the end) (Phase-shift prevention margin) (Refer to axis-

specific parameter No. 76)

27 Maximum

motor

speed

5000

Reference

only

In rpm when a rotary encoder is used, or in mm/sec when a

linear encoder is used (cannot be changed).

28 Maximum

operating

speed

of each axis

1000 1

~

9999

mm/s

29

VLMX speed

1000

1 ~ 9999

mm/s

During VLMX operation, the maximum operating speed of

each axis or VLMX speed, whichever is lower, is used as the

maximum speed of the applicable axis.

30

Servo ON check time

150

0 ~ 5000

msec

Brake equipped:

Time after receiving a servo-ON start

response until start of brake unlocking

Brake not equipped: Time after receiving a servo ON start

response until transition to an

operation-enabled status

31

Offset travel speed at home

return

3 1

~

500

mm/sec

32

Actual distance between

phase Z and end

-1

-1 ~ 99999

0.001 mm

Absolute distance from the end (mechanical or LS).

Obtained automatically if the distance is a negative value.

When multiple actuators are combined, it is recommended to

write the flash ROM after automatic acquisition. (Refer to

axis-specific parameter No. 76)

33 Ideal

distance

between

phase Z and end

0

0 ~ 99999

0.001 mm

Absolute distance from the end (mechanical or LS). (Refer to

axis-specific parameter No. 76)

34 Brake

equipment

specification

0

0 ~ 1

0: Not equipped, 1: Equipped

35

Brake unlock check time

150

0 ~ 3000

msec

Time after receiving a brake-unlock start response until

transition to an operation-enabled status

36

Brake lock check time

300

0 ~ 1000

msec

Time after receiving a brake-lock start response until start of

servo OFF

37

Encoder linear/rotary type

0

0 ~ 1

0: Rotary encoder

1: Linear encoder

38

Encoder ABS/INC type

0

0 ~ 1

0: INC, 1: ABS

39 Magnetic-pole

sensor

equipment specification

(For future expansion =

Change prohibited)

1

0 ~ 1

0: Not equipped, 1: Equipped

40 For

future

expansion

(change prohibited)

0 0

~

1

41 For

future

expansion

(change prohibited)

25 1

~

100

DRVVR

42

Encoder resolution

131072

0 ~

99999999

Pulse/rev,

0.001

Pm/pulse

Pulses (before division)/rev, in the case of a rotary encoder.

0.001

Pm/pulse (before division), in the case of a linear

encoder.

43

Encoder division ratio

3

-7 ~ 7

Pulses are multiplied by (“n”th power of 1/2).

44 Length

measurement

correction

0 -99999999

~ 99999999

0.001 mm/

1M

Valid only for linear movement axes. (Coordinates other than

the encoder reference Z point will change proportionally.)

45

Input polarity of belt

breakage detection sensor

0

0 ~ 2

0: Do not use

1: Contact a

2: Contact b

(Main application version 0.17 or later)

46 (For

expansion)

0

47

Screw lead

20000

1 ~

99999999

0.001 mm

Valid only for linear movement axes.

Invalid in the case of a linear encoder.

48 ~

49

(For expansion)

0

50

Gear ratio numerator

1

1 ~

99999999

Invalid in the case of a linear encoder.

51

Gear ratio denominator

1

1 ~

99999999

Invalid in the case of a linear encoder.

52 (For

expansion)

0

53

Setting bit pattern 1 of each

axis

0 0H

~

FFFFFFFF

H

54

Travel distance for push

stop detection at home

return

20

1 ~ 99999

0.001 mm

Used to confirm push action during home return.

55

Travel distance for push

stop detection at positioning

30

1 ~ 99999

0.001 mm

Used to confirm push action during PUSH command

operation.