Parameters common to all axes, 410 appendix – IAI America SSEL User Manual

Page 432

410

Appendix

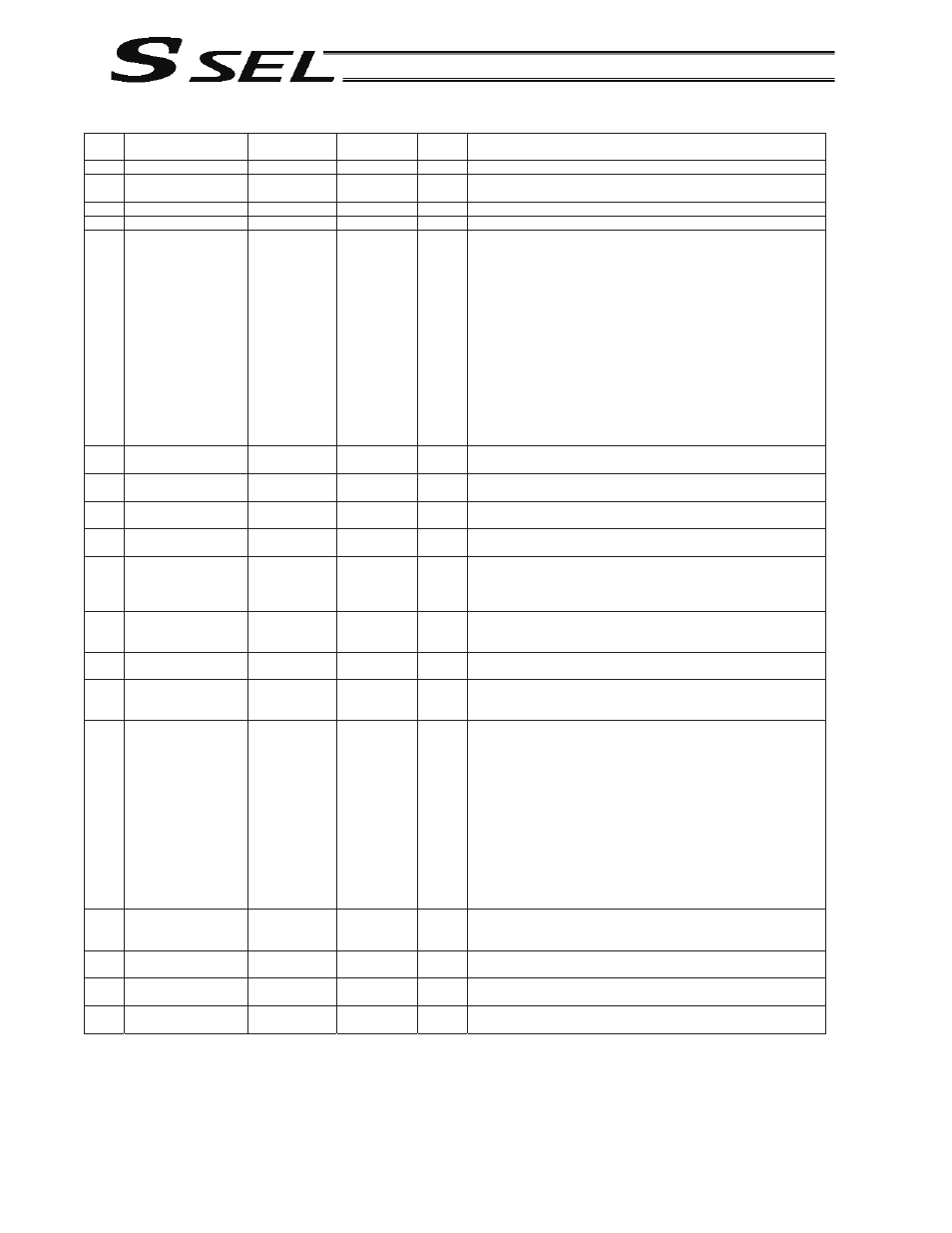

2. Parameters Common to All Axes

No. Parameter

name

Default value

(Reference)

Input range

Unit

Remarks

~

1

Valid axis pattern

0000B

00B ~

11111111B

An OFF bit indicates that no driver is installed.

2

Default override

100

1 ~ 100

Used if not specified in program. (Invalid for SIO operation)

3 ~ 8 (For expansion)

0

~

9

Physical axis pattern

for which enable

switch (deadman

switch/safety gate) is

effective

11111111B 00B

~

11111111B

Not affected by a BASE command. (To make the enable switch

effective for all axes (= it must be effective for all axes, as a rule),

always specify “11111111.” Only when “11111111” is set will the

enable switch be included in the drive-source cutoff factor. If a

value other than “11111111” is set, the drive source will not be cut

off and only the servo of the specified axis will be turned off.)

* All axes are specified if “Other parameter No. 11: Deadman

switch/safety-gate open recovery type” is set to 1 (Reset required

for recovery).

* The drive-source cannot be cut off for axes whose motor-drive

power unit is not housed inside this controller or whose drive-

source cutoff circuit is not controlled by this controller.

* If the optional (custom) specification is available, the optional

(custom) specification will be given priority over the deadman-

switch-enabled physical axis/drive-source cutoff specification,

servo OFF specification or 7-segment display specification.

10

Default TP position

movement axis order

0 0H

~

FFFFFFFFH

11

Default acceleration

30

1 ~ 200

0.01 G

Used if not specified in position data, program or SIO message,

etc.

12

Default deceleration

30

1 ~ 200

0.01 G

Used if not specified in position data, program or SIO message,

etc.

13

Default speed

30

1 ~ 250

mm/s

Used if not specified in SIO message or position data, when

movement is to be continued, etc.

14 Valid

selection

when

operation point data

deceleration is 0

0

0 ~ 5

0: “Deceleration = Acceleration” when the deceleration in the

operation point data is “0”

1: “Deceleration = 0” when the deceleration in the operation point

data is “0”

15 Maximum

jog

speed

when home return is

incomplete

30 1

~

250

mm/s

16 ~

18

(For expansion)

0

~

19

Processing type upon

stationary (non-push)

torque limit over

0

0 ~ 9

0: Operation-cancellation level error (recommended)

1: Operation cancellation (SEL command outputs will turn OFF)

*

Driver errors resulting from overload, etc., will be given priority.

20 Maximum

operating

speed check timing

1

0 ~ 1

0: Check at input

1: Check at operation

* If “Check at operation” is selected, the distribution speed (CP)

of specified speed or the specified speed (PTP) will be

compared against the maximum operating speed of each axis

and clamped at the allowable speed. Accordingly, the system

can achieve its maximum performance in accordance with

the operation command. However, complete check cannot be

performed at input (since the command/operation start

position is indeterminable). In the case of CP, the distribution

speed will vary depending on the operation start position.

Therefore, specifying CP at an unspecified position (first point

movement, etc.) will cause the speed to fluctuate depending

on where the operation is started.

21 Maximum

operating

speed for input value

check

1000

1 ~ 9999

mm/s

If “Input” is selected as the maximum speed check timing, this

parameter will be used to check for input error.

22 Maximum

acceleration

100

1 ~ 999

0.01 G

23 Maximum

deceleration

100

1 ~ 999

0.01 G

24 Minimum

emergency

deceleration

30

1 ~ 300

0.01 G