1 membrane isolation valve – INFICON HAPSITE Smart Plus Chemical Identification System User Manual

Page 34

1 - 6

IP

N 07

4-

47

2-

P1

C

HAPSITE Smart Plus Operating Manual

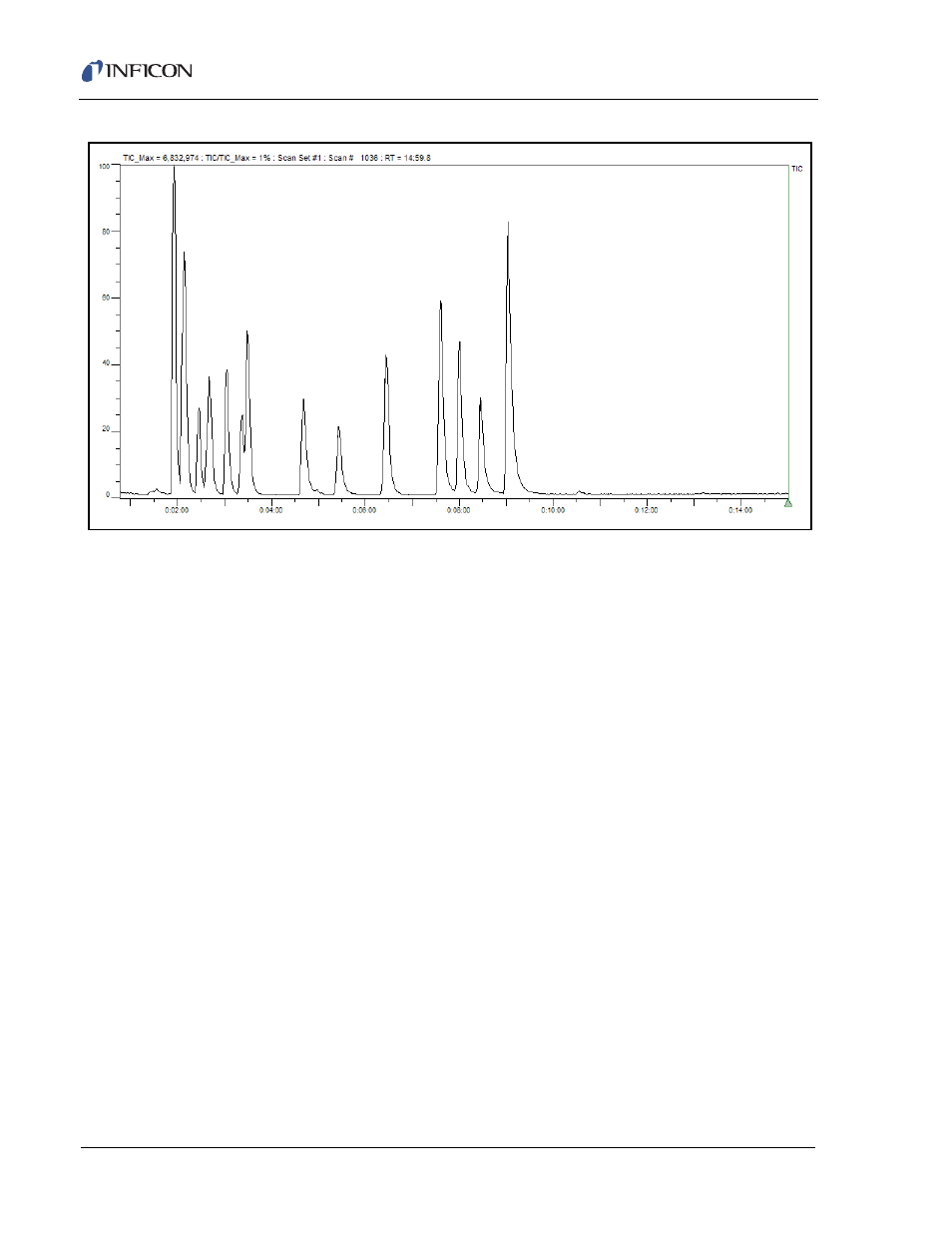

Figure 1-2 Total Ion Chromatogram

The performance of the column is affected by temperature, therefore, the column

is housed in a temperature controlled oven.

The gas chromatograph performs many operational functions, including injecting

the sample, analyzing the sample, flushing the system, and tuning the system.

GC/MS measurement begins with the Sample Pump drawing the gas to be

analyzed into the Sample Loop. It then uses the pressure of the Carrier Gas to flush

the sample from the Sample Loop on to the pre-column and the analytical column.

This step is termed injection.

When the analytes have passed through the pre-column, the Carrier Gas is

directed to the junction of the two columns where the Carrier Gas continues to

transport the analytes through the analytical column while back-flushing the

pre-column to prepare the pre-column for the next analysis sequence. This

back-flush continues throughout the next filling of the Sample Loop.

1.6.1.1 Membrane Isolation Valve

Gas exiting the analytical column crosses the face of a membrane mounted in the

membrane isolation valve. This membrane has the special characteristic of

transmitting the flow of organic compounds to the Mass Spectrometer, while

effectively blocking the flow of inorganic gases (such as the Nitrogen Carrier Gas).

When the membrane isolation valve is opened, the appropriate gases are

permitted to enter the Mass Spectrometer for analysis while the Mass

Spectrometer remains under vacuum. The membrane’s performance is affected by

temperature fluctuations and requires housing in a temperature-controlled zone.