12 service the embosser module, 1 about servicing the embosser module, Service the embosser module – MagTek EC2000 99875607 User Manual

Page 39: 3 - preventive maintenance

3 - Preventive Maintenance

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 39

3.12 Service the Embosser Module

3.12.1 About Servicing the Embosser Module

The embosser module presses characters into card stock by squeezing the card between a raised metal

letter, called a punch, and an indented letter of the same shape, called a die, installed on the embosser’s

top and bottom daisy wheels. For indented characters, the die is replaced with a flat metal plate so the

card stock is only altered on the character side. Worn out punches or dies can produce characters of poor

quality, or characters that are raised/indented less than the required depth.

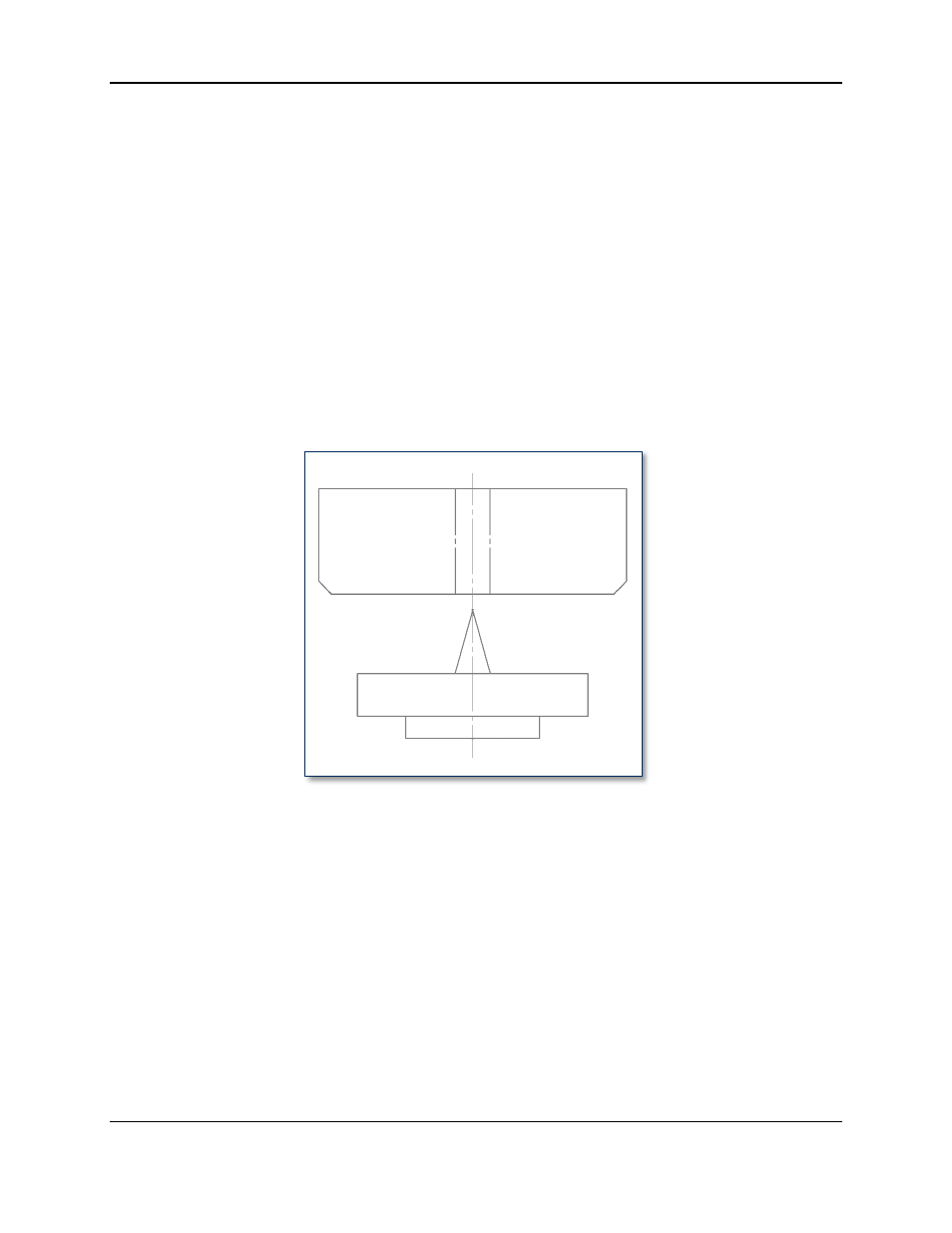

The top and bottom embosser motors each drive a hammer that applies force to the punches and dies on

the daisy wheel. Both hammers have a small round plate with a hole that lines up with a cone on each

character. The cone on each character should be sharp and unbent, and must line up properly with the

hole in the hammer. Figure 3-7 shows a magnified view of a properly aligned hammer (above) and die

(below), viewed from the front of the embosser. Because it can be difficult to see the front of the

embosser module with the EC2000’s cover and other modules installed, it is best to inspect the cones with

an inspection mirror. Section 3.12.2 provides further detail.

Figure 3-7 - Embosser Hammer and Character (FRONT VIEW)