3 calibrate tip angle (pressure), 4 calibrate dwell time, 5 - adjustments – MagTek EC2000 99875607 User Manual

Page 176

5 - Adjustments

ExpressCard 2000| Instant Issuance Card Personalization System | Hardware Service Manual

Page 176

5) If the text is not centered as shown, follow these steps to center it:

a) Navigate to

Menu

>

Settings

>

Tipper

b) If the text was too high inside the rectangle, increase the

Grip Motor Steps

value (steps of 10

work well to start with), put the tipper foil spool assembly back in the EC2000, and repeat these

steps from the beginning.

c) If the text was too low inside the rectangle, decrease the

Grip Motor Steps

value (steps of 10

work well to start with), put the tipper foil spool assembly back in the EC2000, and repeat these

steps from the beginning.

d) Press the

Save

button to save settings, and press

OK

to close the confirmation popup window.

5.8.3 Calibrate Tip Angle (Pressure)

1) Create a tipped sample card from

Menu

>

Samples

.

2) Examine the card’s foil-tipped characters.

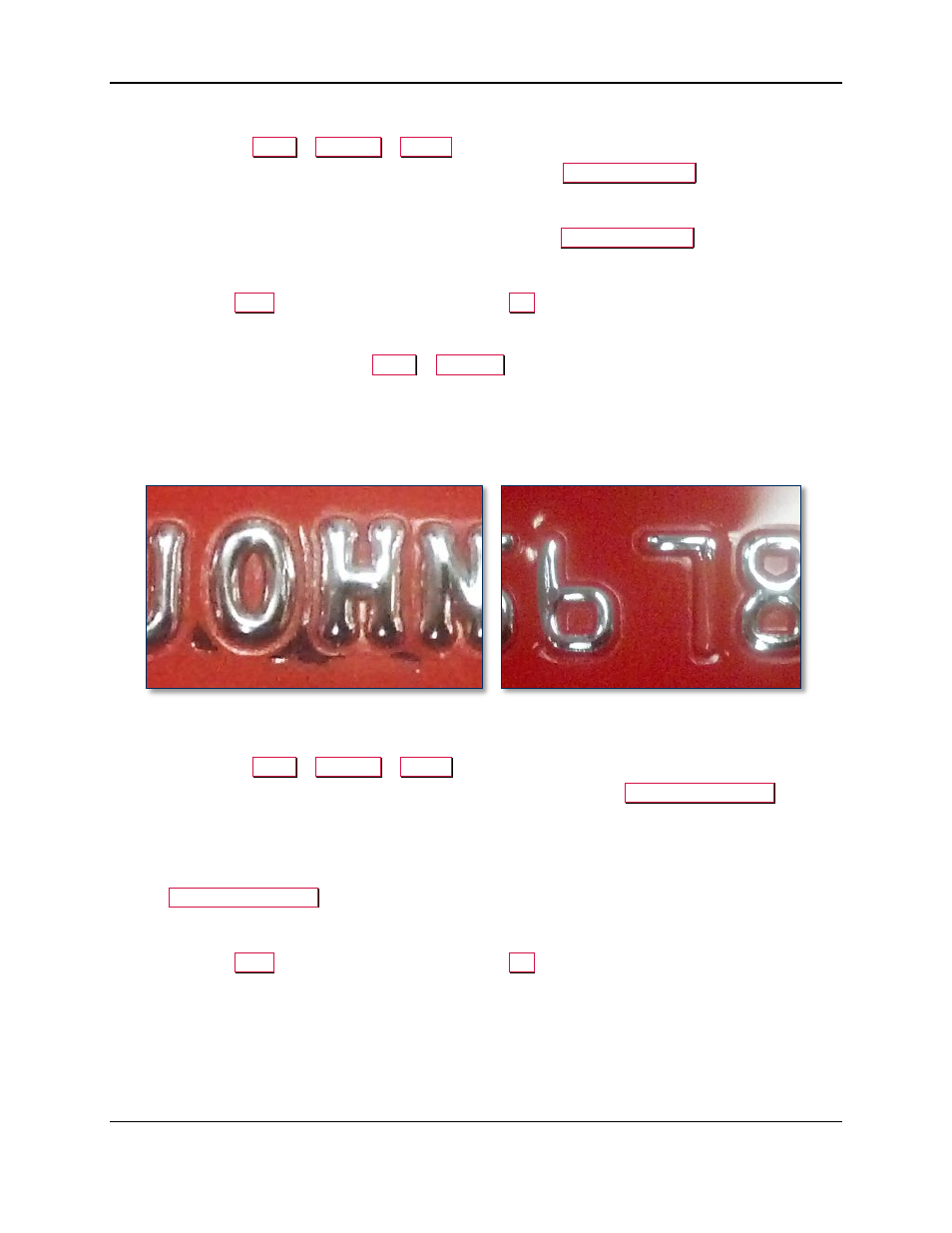

3) Make sure the tipper is not “overflashing” (foil is being put on the flat portion of the card), and is not

leaving embossed characters uncovered. See Figure 5-11. You may also be able to gauge the tipper

calibration by removing and examining the foil.

Figure 5-11 - Tipper Overflashing (Left) and Inadequate Coverage (Right)

4) If the tipper is not calibrated correctly, follow these steps:

a) Navigate to

Menu

>

Settings

>

Tipper

.

b) If the tipper is overflashing, use the arrow buttons to decrease the

Tipper Motor Angle

setting

(subtract 10). If you reduce to the minimum value of 160, stop calibrating the Tipper Motor

Angle setting and notify Engineering. Perform further adjustments by decreasing the Dwell Time

setting.

c) If the tipper is leaving embossed characters uncovered, use the arrow buttons to increase the

Tipper Motor Angle

setting (add 10). If you increase to the maximum value of 210, stop

calibrating the Tipper Motor Angle setting and notify Engineering. Perform further adjustments

by increasing the Dwell Time setting.

d) Press the

Save

button to save settings, and press

OK

to close the confirmation popup window.

e) Repeat these steps from the beginning until the Tipper Motor Angle is properly calibrated.

5.8.4 Calibrate Dwell Time

“Dwell time” is how long the tipper holds the foil on embossed characters during the tipping cycle, and

can be adjusted on the same page as Tipper Motor Angle. A typical dwell time is 100ms.